Method for manufacturing artificial skull restoration prosthesis

A skull and prosthesis technology, applied in the field of plastic reconstruction of skull prosthesis, can solve the problems of affecting the repair effect, easy to pierce the skin, collapse of the repair body, etc., to shorten the preparation period, overcome the mechanical properties, and reduce the side effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

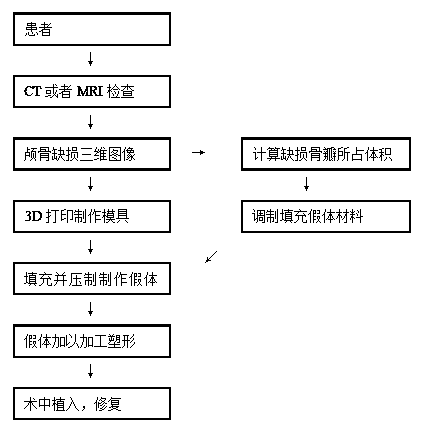

[0017] A method for preparing an artificial skull repair prosthesis, comprising the steps of:

[0018] (1) Using imaging techniques such as CT or MRI, establish a three-dimensional model of the skull repair prosthesis in three-dimensional modeling software;

[0019] (2) According to the data of the three-dimensional model of the prosthesis, 3D printing technology is used to make a skull defect mold;

[0020] (3) The material used for the prosthesis is a material with excellent tissue compatibility with human beings (such as HAP bone cement material and citric acid aqueous solution to form a water and coagulation system);

[0021] (4) Through computer calculation, calculate the volume and other parameters of the required filling prosthesis, and deploy the filling material, so that it is filled into the mold and pressed to achieve the required prosthesis for repairing the skull defect;

[0022] (5) Clean up the printed prosthesis materials and improve individualized shaping.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com