A kind of dissolving method of para-aramid and its application

A para-aramid and solution technology, applied in the field of para-aramid dissolution, to achieve the effects of easy control, good compatibility, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.1g of para-aramid pulp (purchased by Dupont), dissolve 0.1g of dodecylbenzenesulfonic acid in 2g of DMSO, put in the aramid pulp and stir well, heat to 50°C, and ultrasonically After 48 hours, stand still at 20°C until it becomes transparent, and remove a small amount of undissolved para-aramid in the lower layer by filtration to obtain a para-aramid solution with a mass fraction of 5%.

Embodiment 2

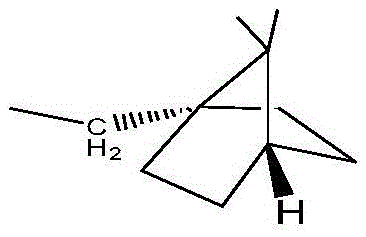

[0033] Weigh 0.15g of para-aramid pulp, dissolve 0.3g of camphorsulfonic acid in 4g of m-cresol, put in the aramid pulp and stir well, heat to 60°C, ultrasonic for 36h, and stand still at 25°C until transparent, remove a small amount of undissolved para-aramid in the lower layer by filtration, and obtain a para-aramid solution with a mass fraction of 3.75%.

Embodiment 3

[0035] Weigh 0.2g of para-aramid pulp, take 0.25g of C 8 h 17 Dissolve COOH in 2g of toluene, put in aramid pulp and stir evenly, heat to 60°C, ultrasonicate for 64 hours, stand still at 35°C until transparent, filter to remove a small amount of undissolved para-aramid in the lower layer, and obtain a mass fraction of 8% para-aramid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com