Silicone sealant and its preparation method

A technology of silicone sealant and hydroxy polysiloxane, applied in the field of sealant, can solve problems such as carbon chain breakage, high viscosity peak, and slow rubber vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

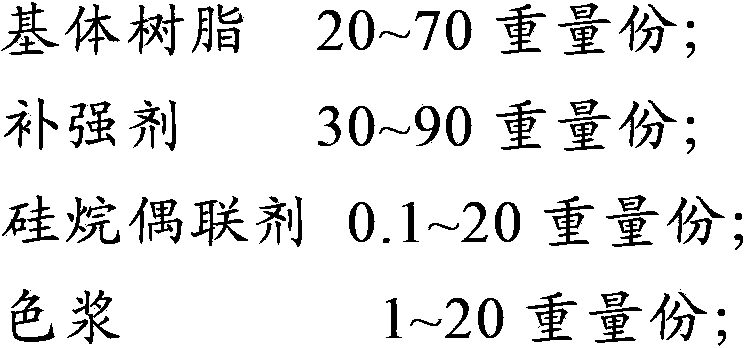

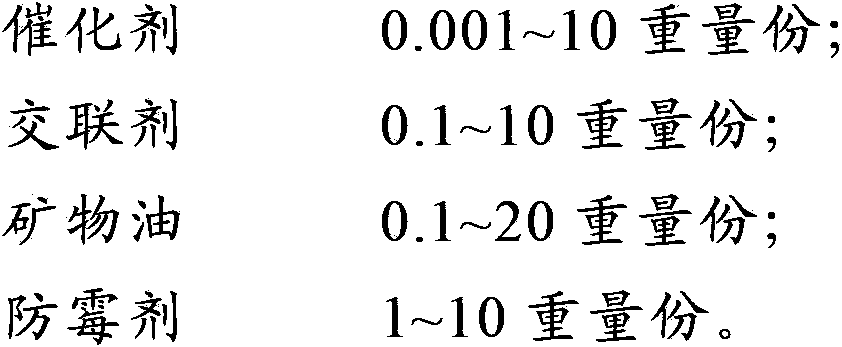

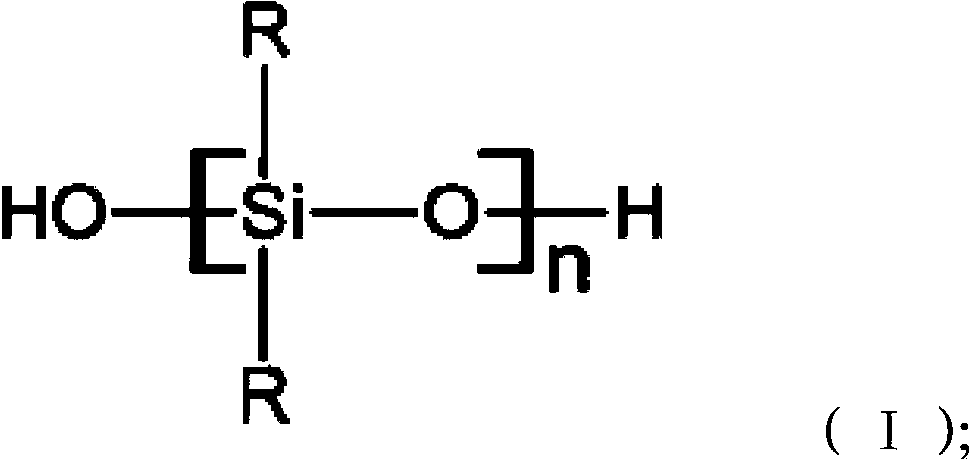

[0036] The present invention also provides a preparation method of silicone sealant, comprising: mixing 20-70 parts by weight of matrix resin and 30-90 parts by weight of reinforcing agent, and stirring to obtain the base glue;

[0037] 0.1-20 parts by weight of silane coupling, 1-20 parts by weight of color paste, 0.001-10 parts by weight of catalyst, 0.1-10 parts by weight of cross-linking agent, 0.1-20 parts by weight of mineral oil, 1-10 parts by weight of One part antifungal agent is mixed with the base glue and stirred to obtain stone silicone sealant.

[0038] According to the present invention, in the process of preparing the silicone sealant, the preparation of the base glue is first carried out, and the base glue is the colloid obtained by mixing the matrix resin and the reinforcing agent. In order to make the performance of the silicone sealant better Excellent, as a preferred solution, the preparation method of the base glue is specifically:

[0039] Put 1 / 2~2 / 3 of ...

Embodiment 1

[0048] Preparation of base glue Start the kneader and pump in 25 parts by weight of α, ω-dihydroxy polysiloxane, feed while kneading, adjust the speed of the kneader to 50r / min; gradually put in 60 parts by weight of active nano-calcium carbonate and 10 parts by weight of heavy calcium carbonate, the rotating speed of the kneader is 50r / min, the temperature of the kneading material is 110°C, the rotating speed is 50r / min, when the kneading temperature rises to 110°C, the vacuum is pumped to -0.04~-0.1 After kneading for 4 hours at Mpa; then vacuumize the kneader, open the thinner valve, pump in the remaining 25 parts by weight of α, ω-dihydroxypolysiloxane, adjust the speed of the kneader to 50r / min, and wait until the base resin is completely pumped. After filling, close the suction valve, open the vacuum valve, evacuate to -0.04~-0.1Mpa, vacuumize and knead for 2 hours, remove the vacuum and turn on the circulation pump, and circulate for 10 minutes while stirring at a speed ...

Embodiment 2

[0052] Preparation of the base glue Start the kneader and pump in 10 parts by weight of α, ω-dihydroxypolysiloxane, feed while kneading, adjust the speed of the kneader to 50r / min, and gradually put in 70 parts by weight of active nano Calcium carbonate and 20 parts by weight of light calcium carbonate, the speed of the kneader is 50r / min, kneading until the temperature of the material rises to 110 ° C; Knead for 4 hours after Mpa, the speed of the kneader is 50r / min. Then the vacuum is released, the thinner valve is opened, and the remaining 10 parts by weight of α, ω-dihydroxypolysiloxane is sucked in. The rotating speed of the kneader is 50r / min. After the base resin is completely sucked in, the suction valve is closed. Open the vacuum valve, evacuate to -0.04~-0.1Mpa, evacuate and knead for 2 hours, remove the vacuum and turn on the circulation pump, and circulate for 10 minutes while stirring at a speed of 50r / min to obtain the base glue.

[0053] The preparation of colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com