A crucible-free wall-contact single crystal growth method based on a necked crucible

A growth method and contact technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of difficult to control the solid-liquid interface, difficult to improve the quality of the single crystal, difficult to control the melt convection, etc. The effect of separating deviation and preventing melt volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

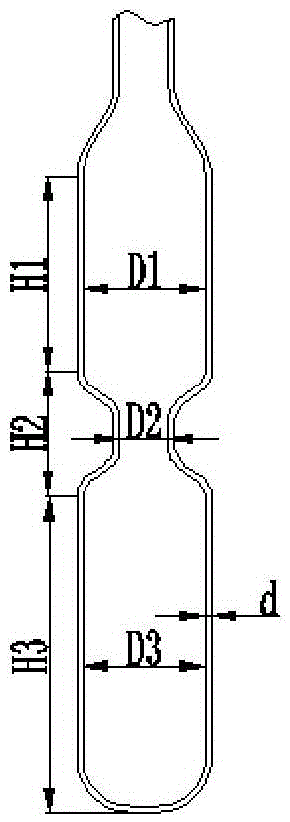

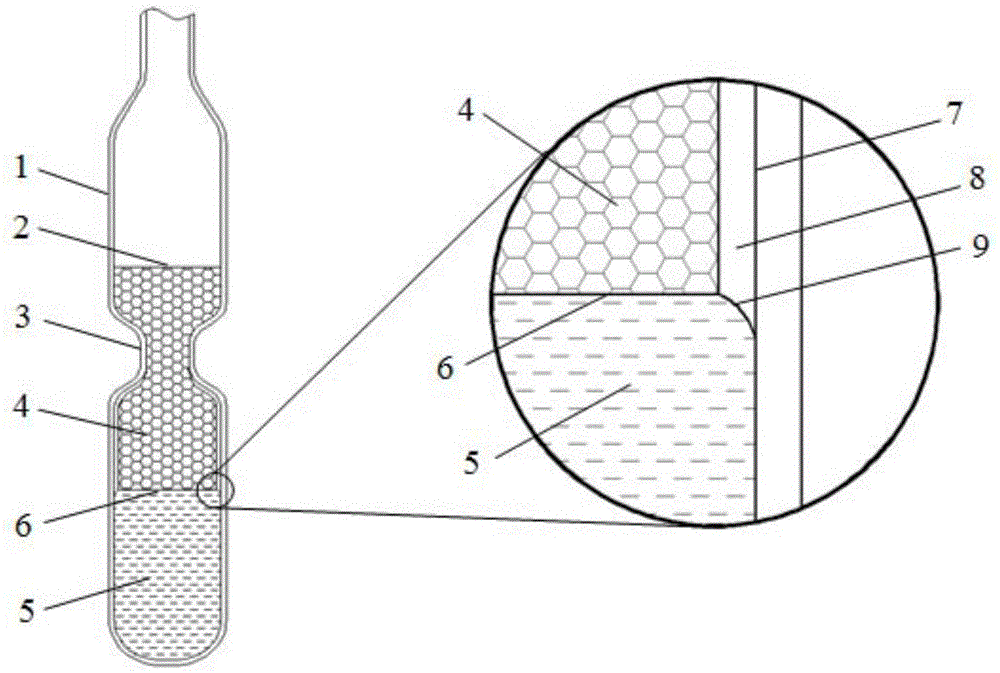

[0041] 1 design crucible 1. The material of the crucible can be quartz, and the structure of the crucible is as follows: figure 2 As shown, the inner diameters D1 and D3 of the crucible are 120mm, the inner diameter D2 at the constriction is 20mm, the wall thickness d of the crucible is 3.5mm, H1 is 100mm, H2 is 60mm, and H3 is 150mm.

[0042] 2 Coating carbon on the inner surface of the quartz crucible. Vacuum the quartz crucible (vacuum degree ~ 5×10 ‐6 Pa), heated to about 900 degrees, filled with an appropriate amount of high-purity methane gas, the methane gas will be cracked at high temperature, and a carbon film will be formed on the inner surface of the crucible.

[0043] 3 Press Cd 0.96 Zn 0.04 The stoichiometric ratio of Te weighs the raw materials of tellurium (Te), zinc (Zn) and cadmium (Cd) with a purity of 7N (99.99999%) respectively. The total weight of the raw materials is about 13.8kg. into the crucible.

[0044] 4 Vacuum the quartz crucible (vacuum deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com