Test method of stretching stress-strain curve of ceramic matrix composite material

A technology of composite materials and tensile stress, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high processing accuracy and the inability to measure the tensile stress-strain curve of ceramic matrix composite materials, etc., to achieve The effect of low machining accuracy requirements, easy implementation, and high test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

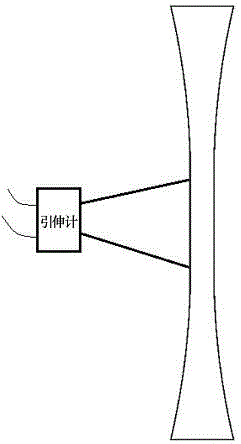

[0030] (1) Select a ceramic matrix composite plate with a length L of 120 mm and a width W of 10 mm, and process it into a dovetail-shaped specimen, such as figure 2 shown;

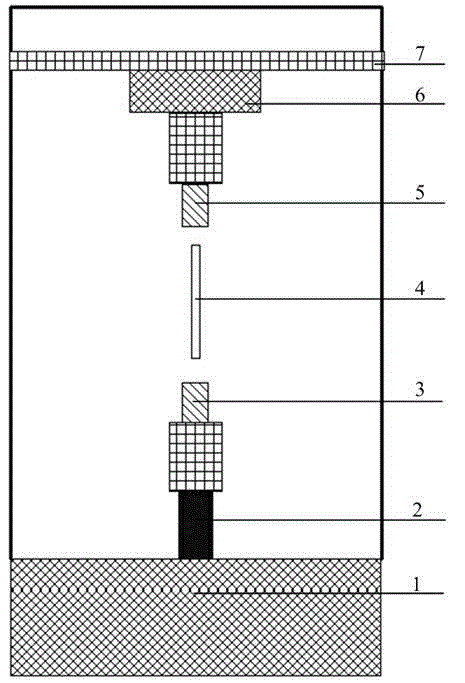

[0031] (2) Load the fixture with dovetail-shaped tenon groove on the chuck of the tensile testing machine, and then use the centering device to ensure the centering of the upper and lower chucks, and then snap the dovetail-shaped test piece into the tenon groove;

[0032] (3) First, fix the extension rod of the extensometer on both ends of the test section of the dovetail-shaped specimen, then connect the extensometer signal line to the computer of the tensile testing machine, measure and record the strain data of the dovetail-shaped specimen, such as image 3 shown;

[0033] (4) Start the tensile testing machine, adjust the lower chuck to move downward through the actuator, so that the dovetail-shaped test piece bears a small tensile force;

[0034] (5) Start the heating device, heat the dovetail-shap...

Embodiment 2

[0038] (1) Select a ceramic matrix composite plate with a length L of 120 mm and a width W of 10 mm, and process it into a dog-bone-shaped specimen, such as image 3 shown;

[0039] (2) Cut an aluminum reinforcement sheet of the same size and shape as the clamping section of the dog-bone-shaped specimen, and paste the reinforcement sheet on the clamping surface of the dog-bone-shaped specimen with high-strength structural adhesive. Put the dog-bone-shaped test piece into the chuck of the tensile testing machine to adjust the centering, and then clamp the dog-bone-shaped test piece.

[0040] (3), first paste the strain gauge on the strain gauge on the surface of the test section of the dog-bone specimen, then connect the strain gauge to the strain gauge, and finally connect the strain gauge to the computer of the tensile testing machine to measure and record the dog bone The strain data of the test piece, such as Figure 5 shown;

[0041] (4) Start the tensile testing machin...

Embodiment 3

[0045] Step (3) is to first aim the camera of the non-contact tester at the test section of the dog-bone-shaped specimen, and then connect the non-contact tester to the computer of the tensile testing machine to measure and record the strain data of the dog-bone-shaped specimen, such as Image 6 shown. All the other steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com