Middle-infrared band broadband cycle wave-absorbing material

A wave-absorbing material and infrared band technology, applied in optical components, optics, instruments, etc., can solve the problems of single frequency band and narrow absorption frequency band, and achieve the effect of expanding bandwidth, wide absorption frequency band, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

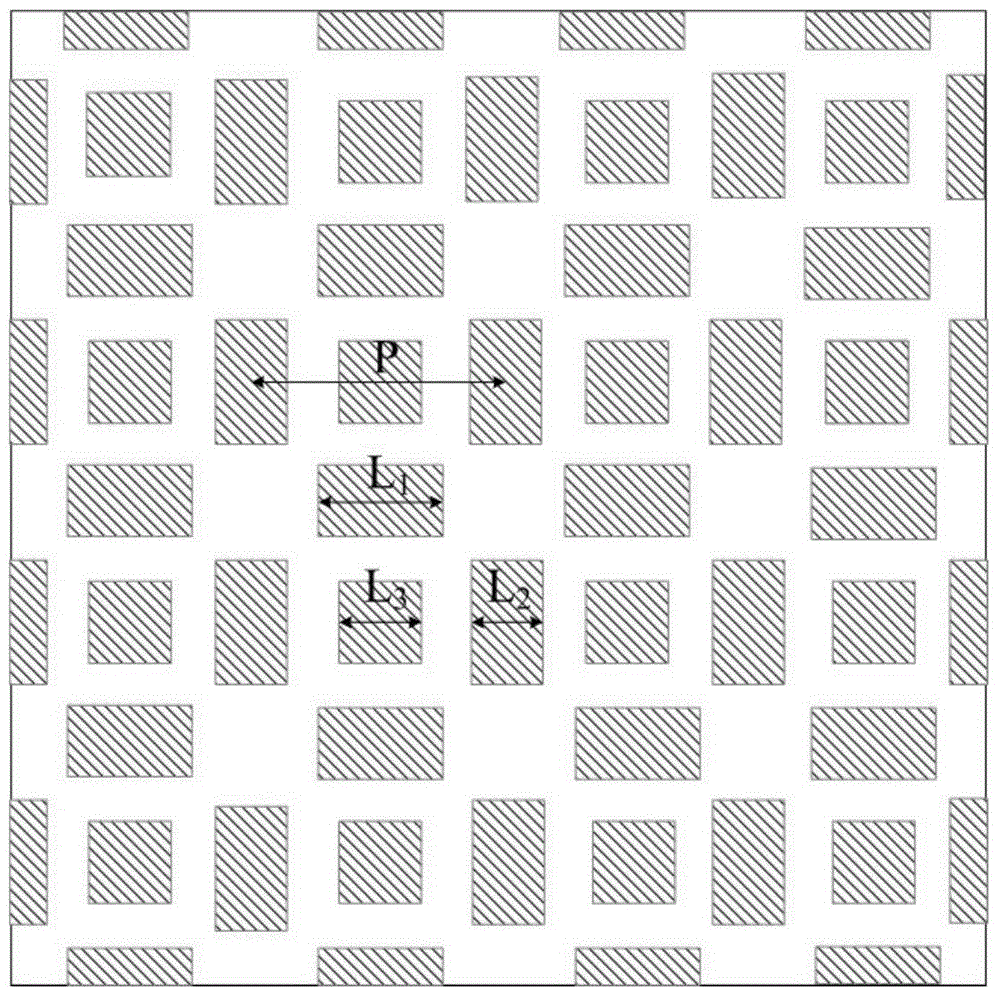

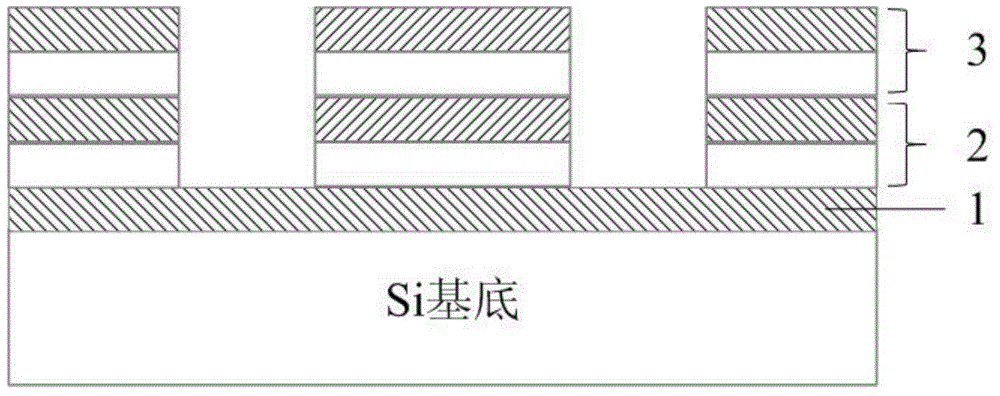

[0027] like figure 2 As shown, a double-layer "metal-dielectric" resonant layer structure and a periodic absorbing structure composed of a continuous metal film on the bottom layer are used to realize the broadband absorbing structure BM-1. On the supporting Si substrate, there is first a continuous metal Al thin film 1 with a thickness of 100nm, and a double-layer "metal-medium" resonant layer structure on it. The medium in the lower resonance layer 2 is Y with a thickness of 100nm 2 o 3 thin film, the real part of its dielectric constant is 3.21, and the medium in the upper resonant layer 3 is Al with a thickness of 150nm 2 o 3 The real part of the dielectric constant of the thin film is 2.28, and the thickness of the metal patch layer in the two resonant layers is both 50nm. The period of BM-1 is P=4.7μm, and the size of the patch in the resonant unit is L 1 =1.7μm, L 2 =1.5μm, L 3 =1.6μm. Its absorption rate curve is as Figure 4 As shown in the figure, it can be...

specific Embodiment approach 2

[0028] like figure 2 As shown, a double-layer "metal-dielectric" resonant layer structure and a periodic absorbing structure composed of a continuous metal film on the bottom layer are used to realize the broadband absorbing structure BM-2. On the supporting Si substrate, there is first a continuous metal Al film with a thickness of 100nm, and a double-layer "metal-medium" resonant layer structure on it. The medium in the lower resonance layer is Al with a thickness of 100nm 2 o 3 Thin film, the real part of its dielectric constant is 2.28, and the medium in the upper resonant layer is MgF with a thickness of 150nm 2 The real part of the dielectric constant of the thin film is 1.75, and the thickness of the metal patch layer in the two resonant layers is both 50nm. The period of BM-1 is P=4.7μm, and the size of the patch in the resonant unit is L 1 =1.7μm, L 2 =1.5μm, L 3 =1.6μm. Its absorption rate curve is as Figure 5 As shown, it can be seen from the figure that d...

specific Embodiment approach 3

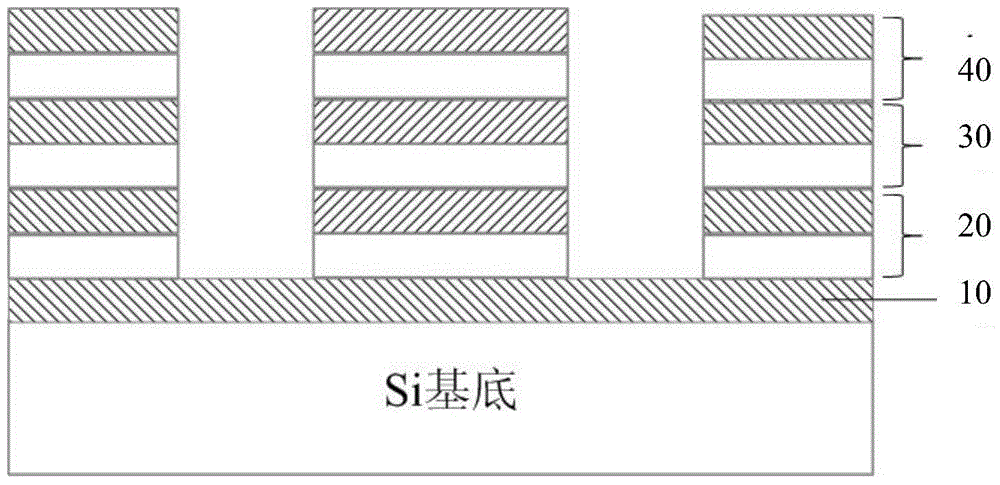

[0029] like image 3 As shown, a three-layer "metal-dielectric" resonant layer structure and a periodic absorbing structure composed of a continuous metal film on the bottom layer are used to realize the broadband absorbing structure BM-3. On the supporting Si substrate substrate, there is first a continuous metal Al film 1 with a thickness of 100nm 0 , above which is a three-layer "metal-dielectric" resonant layer structure. Bottom resonant layer 2 0 The medium in the medium is MgF with a thickness of 150nm 2 Thin film, the real part of its dielectric constant is 1.75, the middle resonant layer 3 0 The medium in the medium is Al with a thickness of 100nm 2 o 3 thin film with a real part of the dielectric constant of 2.28 and a top resonant layer of 4 0 The medium in the medium is Y with a thickness of 150nm 2 o 3 The real part of the dielectric constant of the thin film is 3.21, and the thickness of the metal patch layer in the three resonant layers is 50nm. The peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com