Fuzzy Temperature Control Method and Control System Based on State Machine

A fuzzy control and fuzzy controller technology, applied in the field of temperature sensors, can solve problems such as low efficiency, hysteresis, and unintuitive control system testing and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

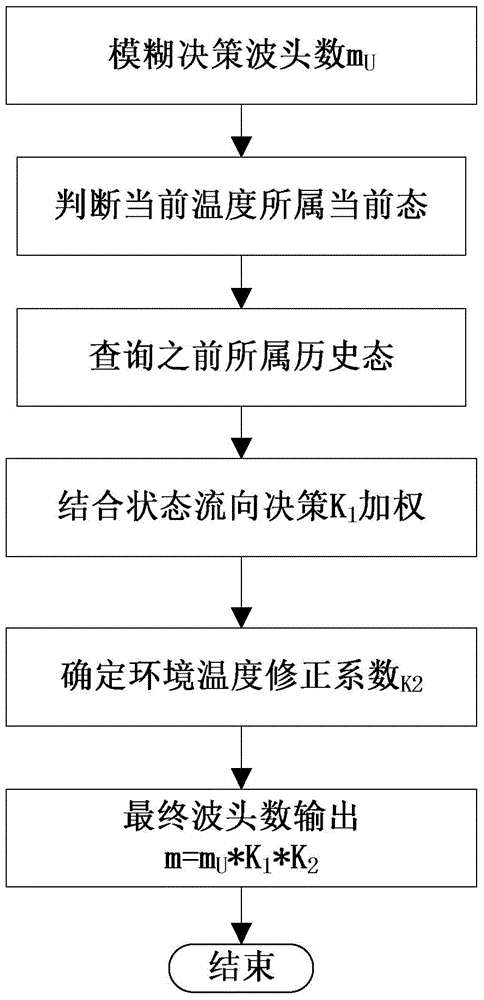

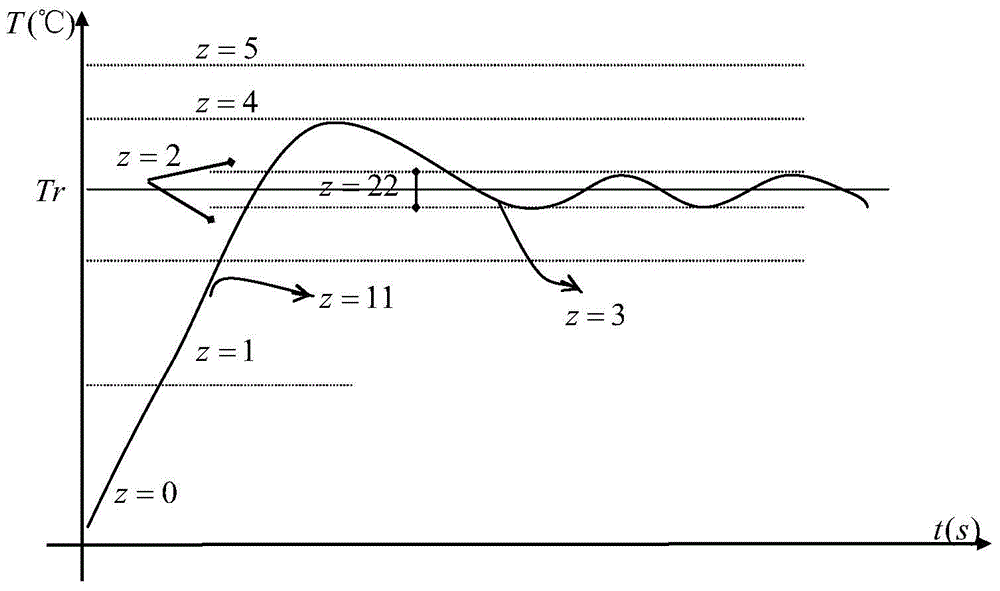

[0043] The temperature fuzzy control method based on the state machine of the present invention, refer to figure 1 , first of all, according to the experiment, the temperature response under normal circumstances will be divided into multiple states, and the conversion flow of the state machine will be weighted for the subsequent final control output;

[0044] Then the temperature deviation e(T) and the deviation rate ec(T) are fuzzy into multiple intervals respectively, and the ranges of the temperature deviation e(T) and the deviation rate ec(T) are respectively set, and then the temperature deviation is made The ranges of e(T) and deviation rate ec(T) are normalized to the same fuzzy set universe;

[0045] Then, according to the temperature operation characteristics in the experiment, the fuzzy control rule table is established, and then the output U is obtained from the fuzzy control rule table, and the fuzzy output U is solved by the "maximum membership degree" method, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com