Photomultiplier of electrostatic focusing micro-channel plates

A photomultiplier tube and microchannel plate technology, applied in the direction of electron multiplier tubes, electron multiplier details, electron multiplier anode devices, etc., can solve the problems of slow progress, unpredictable resistance, low coverage, etc. The effect of time difference, high gain, and reduction of signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments. It should be noted that the embodiments described here are for illustration only and do not limit the present invention.

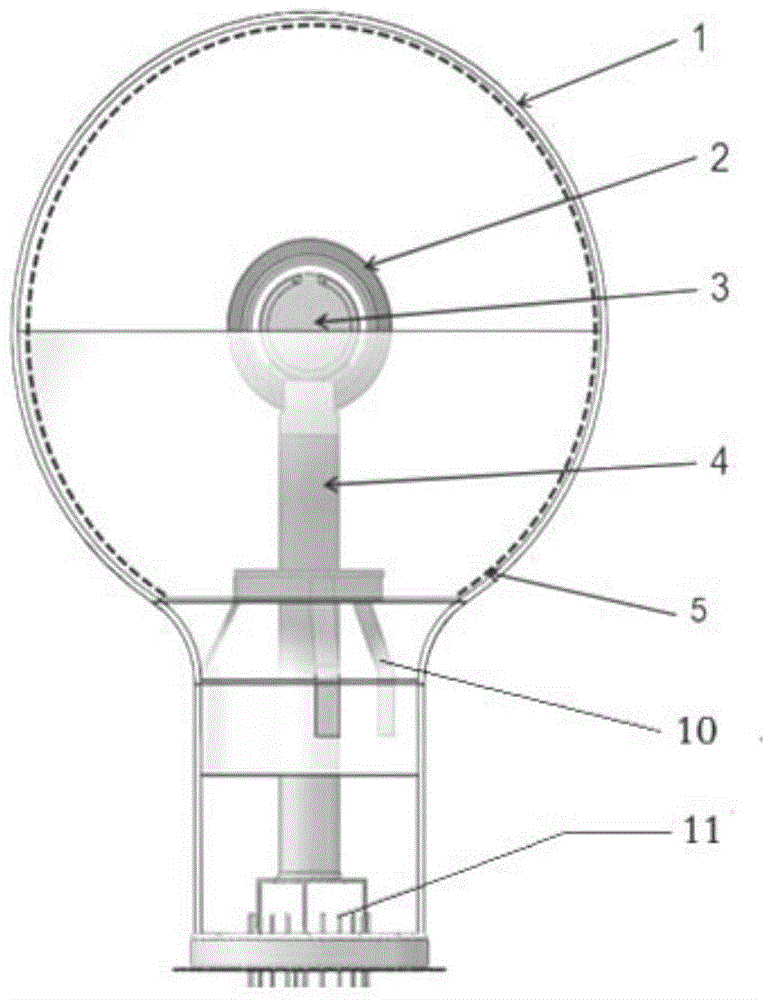

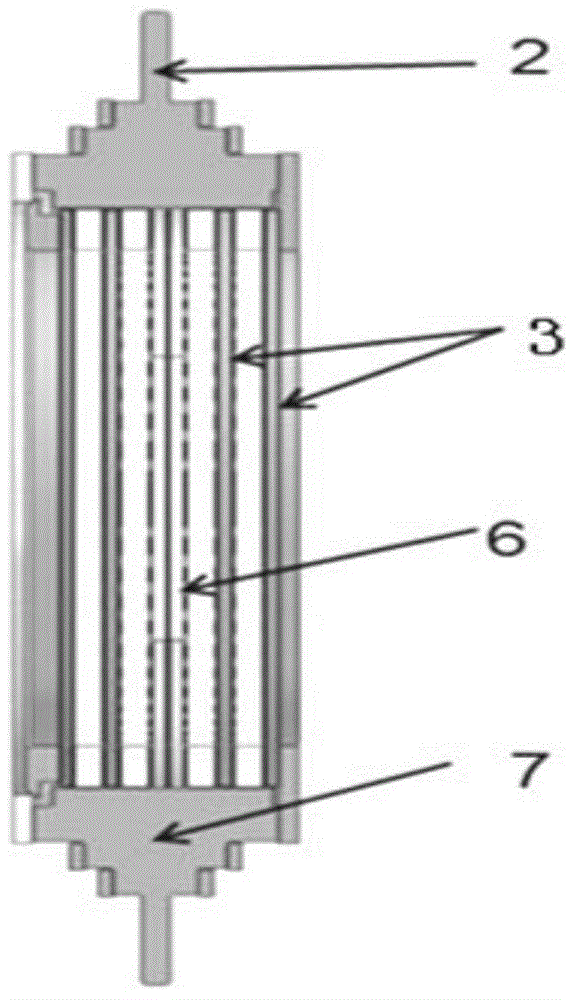

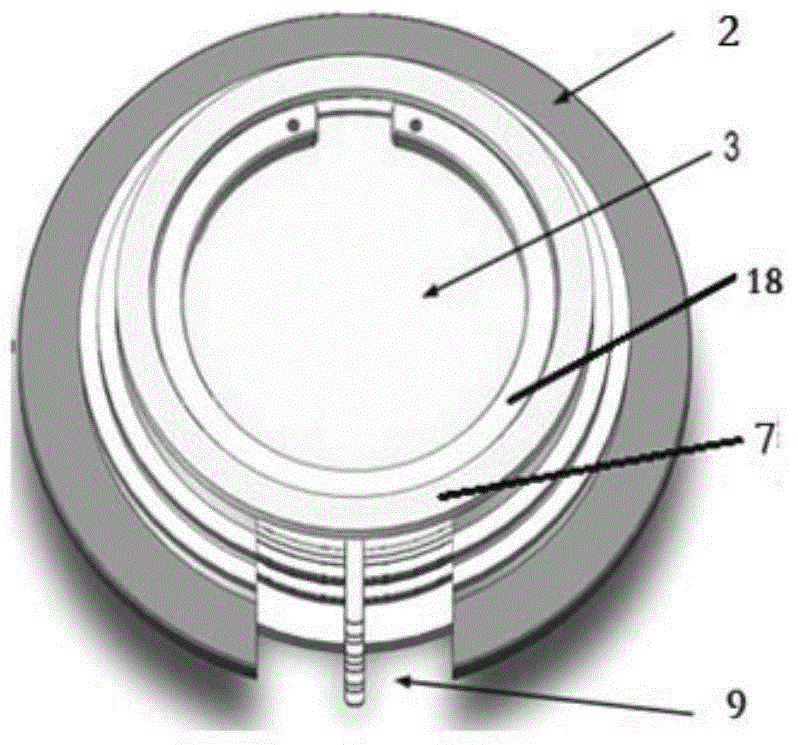

[0038] Such as figure 1 As shown, the photomultiplier tube of the first embodiment of the present invention mainly includes a spherical or ellipsoidal vacuum vessel 1 made of glass, a photocathode 5 attached to the inner surface of the glass, a focusing electrode 2, an electron multiplier 3, and an anode 6 ( See figure 2 ) and support column 4, focusing electrode 2, electron multiplier 3, and anode 6 are integrated through ceramic skeleton 7 (such as figure 2 shown), the centers of the three are coaxial, and are fixed at the center of the vacuum vessel 1 by the support column 4, and the support column 4 is fixed by the three claws 10 and the glass core column 11 below.

[0039] The electron multiplier of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com