Fluidized bed reactor of biomass tar

A fluidized bed reactor and biomass technology, which is applied in chemical refining tar processing, hydrocarbon oil treatment, petroleum industry and other directions, can solve problems such as increasing production process, subsequent process equipment damage, damage, etc., to reduce solid deposition, The effect of reducing production costs and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

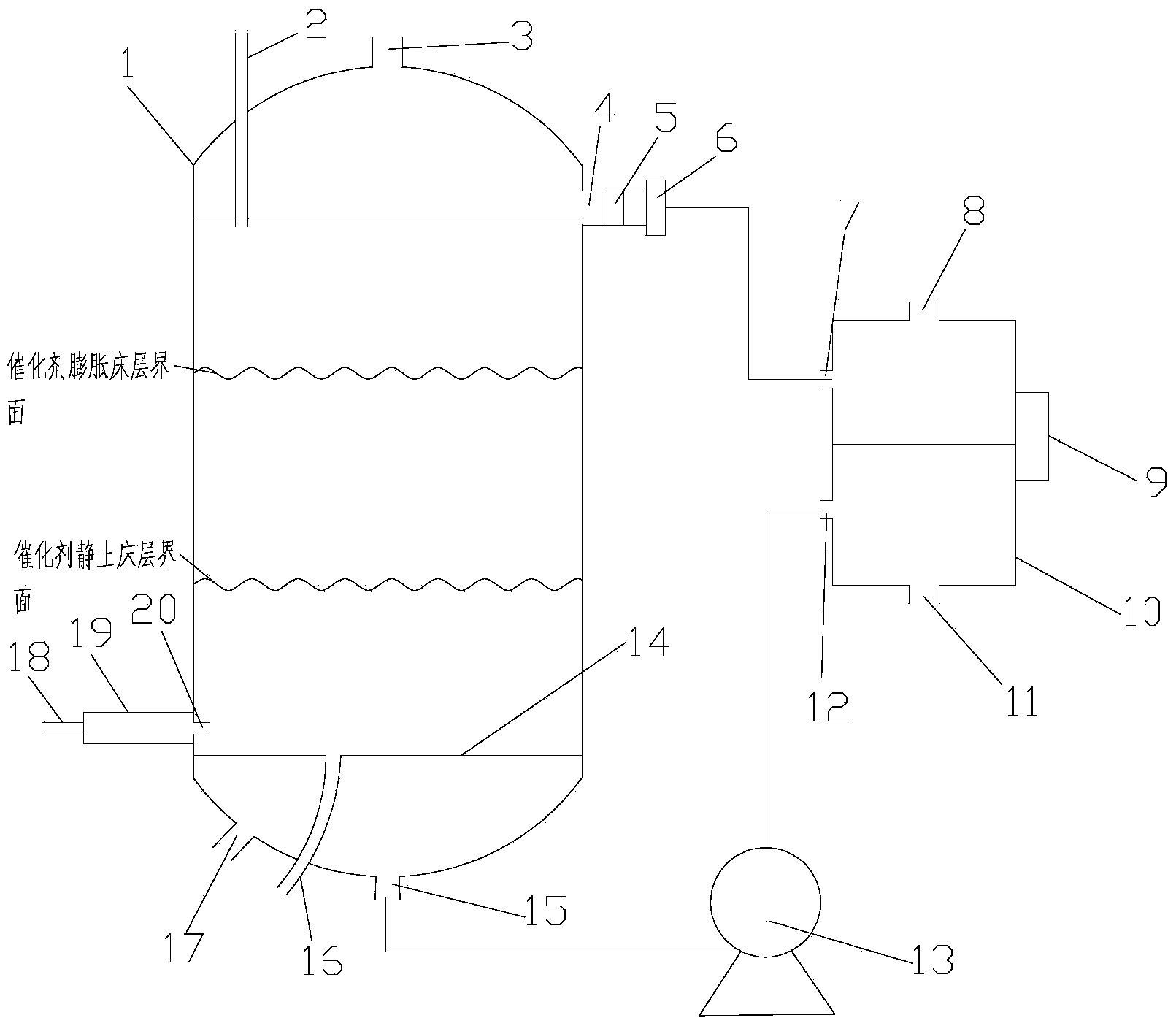

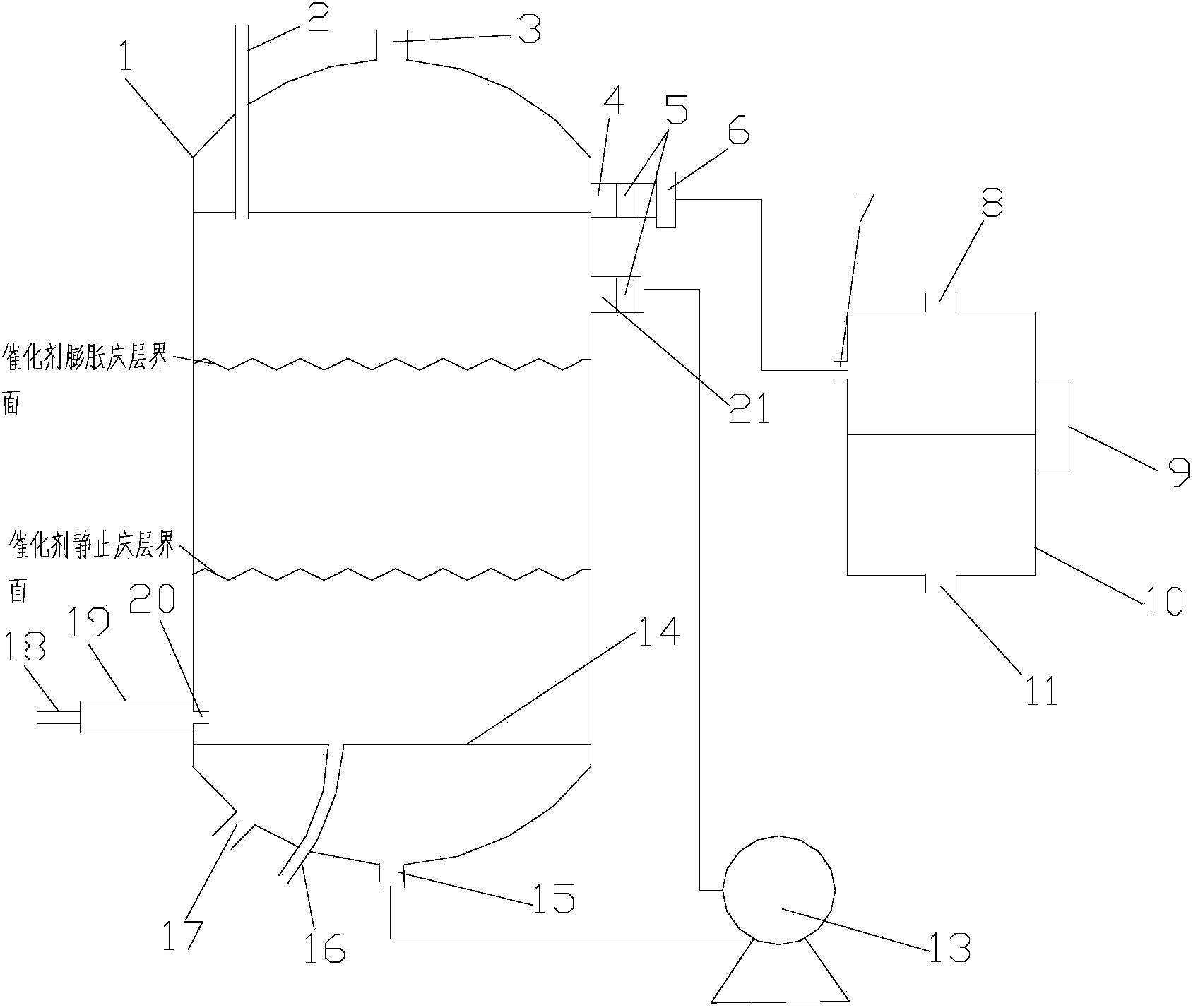

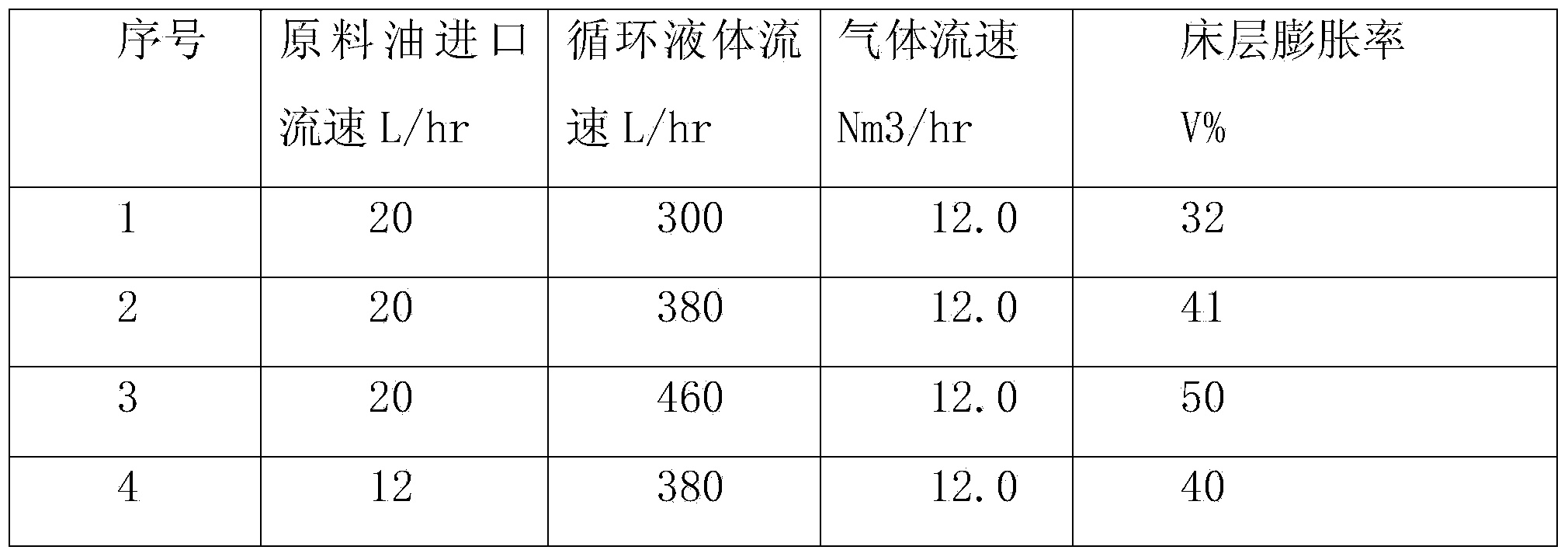

[0021] figure 1 It is a structural schematic diagram of the first embodiment of the present invention, figure 2 It is a structural schematic diagram of the second embodiment of the present invention, as shown in the figure, a kind of ebullating bed reactor of biomass tar provided by the present invention at least includes a reactor shell 1 for accommodating reaction materials, and the reactor shell The lower part of the body 1 is fixedly provided with a distributor 14, and the reactor shell 1 is provided with a raw material inlet and a product outlet, and the raw material inlet at least includes a biomass tar inlet 20, and the biomass tar inlet 20 is arranged in the reactor. The lower part of the side wall of the device housing 1 is located above the distributor 14. The function of the distributor 14 is to better allow the raw materials, circulating liquid and hydrogen to mix evenly and react with the catalyst evenly. The distributor 14 Bubble cap type, grid plate type, orif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com