Modified hollow microsphere and application thereof

A hollow microsphere and hollow microbead technology, which is applied in the preparation of microspheres, microcapsule preparations, coatings, etc., can solve the problems of high areal density and narrow absorption band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of aluminum modified hollow microsphere composite coating

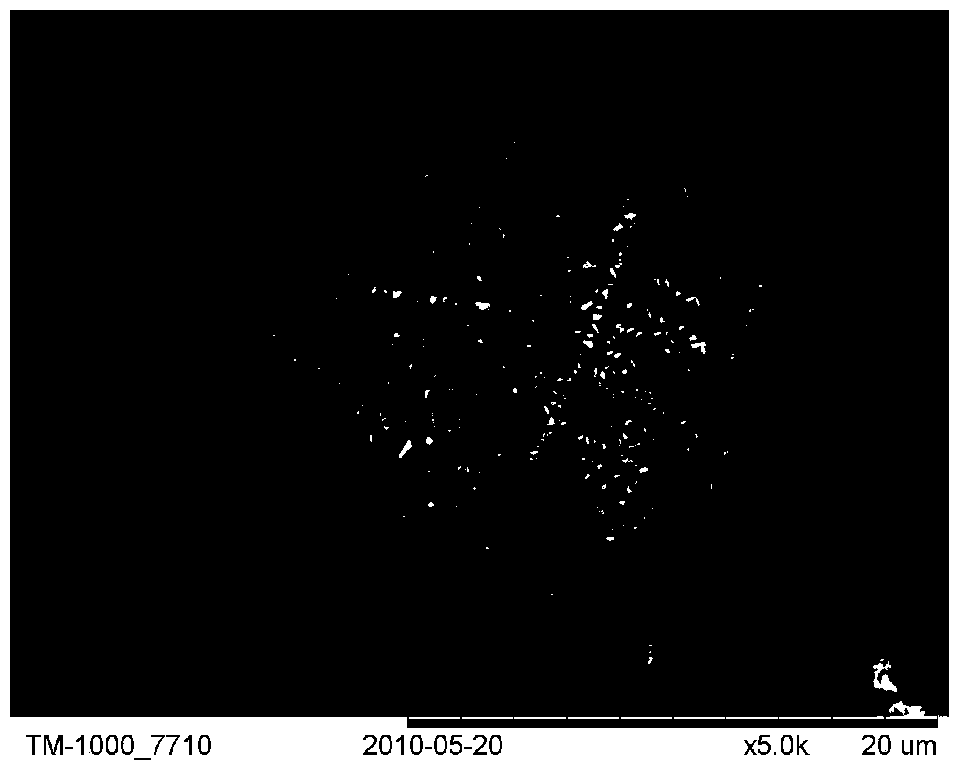

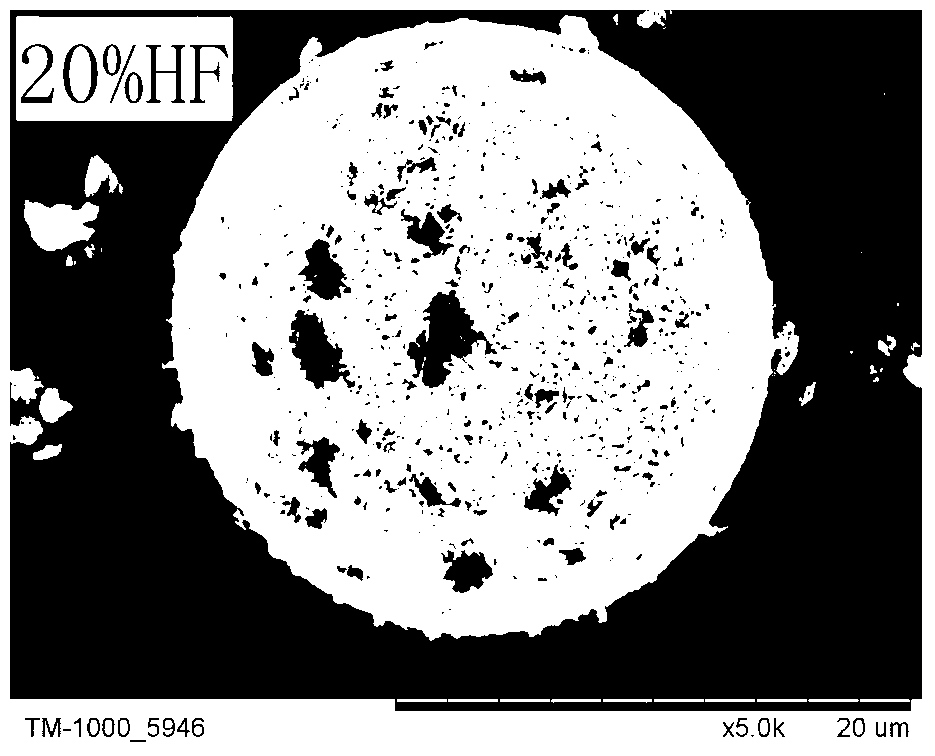

[0026] (1) Preparation of Aluminum Modified Hollow Microspheres

[0027] 1) Pretreatment of hollow microspheres: 20 g of hollow ceramic microspheres were placed in a mixed cleaning reagent, washed at room temperature for 2 hours, rinsed repeatedly with deionized water, and then dried. Add the cleaned hollow ceramic microbeads into 5% hydrofluoric acid solution to roughen them for 5 minutes, then filter them with suction, wash them repeatedly with deionized water, and dry them. The mixed cleaning reagent is: every liter of mixed cleaning reagent contains 50g NaOH, 15g NaOH 2 CO 3 , 15g Na 3 PO 4 and 5g Na 2 SiO 3 , and the balance is water.

[0028] 2) Modification of the hollow microspheres: soak 5 g of the pretreated hollow microspheres obtained in step 1) in 200 mL of distilled water, add 200 ml of 0.25 mol / L aluminum sulfate solution at a constant rate, adjust the pH of the soluti...

Embodiment 2

[0041] Embodiment 2: A kind of aluminum modified hollow microsphere composite coating

[0042] (1) Preparation of Aluminum Modified Hollow Microspheres

[0043] 1) Pretreatment of hollow microspheres: 20 g of hollow ceramic microspheres were placed in a cleaning reagent (50 g / L NaOH solution), washed at room temperature for 2 hours, rinsed repeatedly with deionized water, and then dried. Add the cleaned hollow ceramic microbeads into 5% hydrofluoric acid solution to roughen them for 5 minutes, then filter them with suction, wash them repeatedly with deionized water, and dry them.

[0044] 2) Modification of hollow microspheres: soak 5 g of the pretreated hollow microspheres obtained in step 1) in 200 mL of distilled water, add 0.25 mol / L aluminum sulfate and 0.5 mol / L sodium silicate solution (aluminum sulfate mixed with sodium silicate to obtain an aluminum silicate solution), the pH of the solution was adjusted to 4 with ammonia water, and the stirring was continued for 2 h...

Embodiment 3

[0055] Embodiment 3: A kind of zinc modified hollow microsphere composite coating

[0056] (1) Preparation of zinc-modified hollow microspheres

[0057] 1) Pretreatment of hollow microspheres: 20 g of hollow glass microspheres and hollow ceramic microspheres were placed in a mixed cleaning reagent, washed at room temperature for 2 hours, rinsed repeatedly with deionized water, and then dried. Add the cleaned hollow ceramic microbeads to 5% hydrofluoric acid solution to roughen them for 1 min, then filter them with suction, rinse them repeatedly with deionized water, and dry them. The mixed cleaning reagent is: every liter of mixed cleaning reagent contains 50g NaOH and 15g NaOH 2 CO 3 , and the balance is water.

[0058] 2) Modification of the hollow microspheres: soak 5 g of the pretreated hollow microspheres obtained in step 1) in 200 mL of distilled water, add 200 ml of 0.25 mol / L zinc nitrate solution at a constant rate, and adjust the pH of the solution with urea to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com