Method for preparing graphene powder by using dry process

A technology of graphene powder and graphite, which is applied in the field of dry preparation of graphene powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

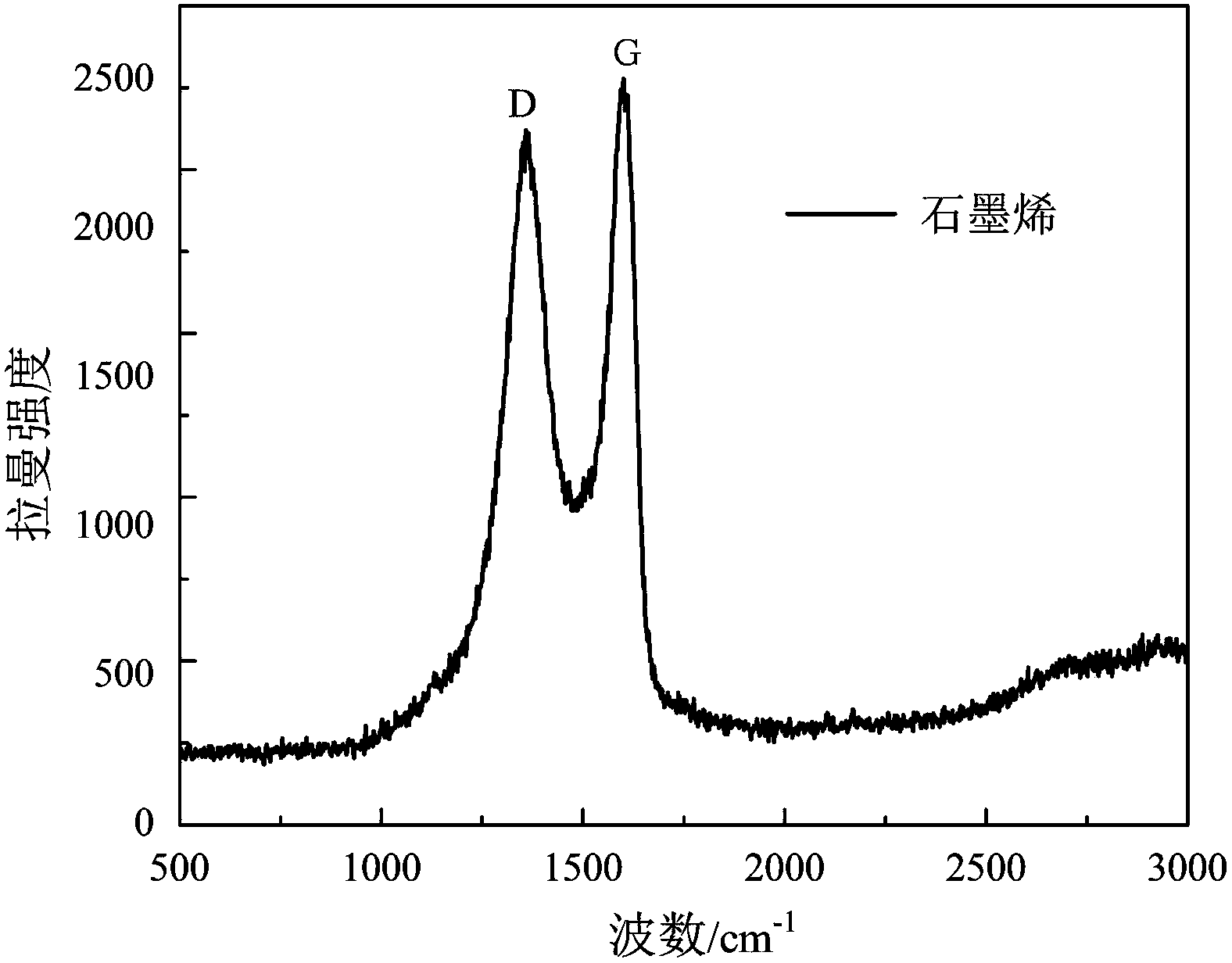

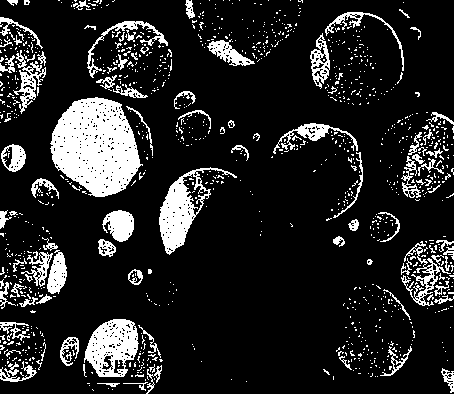

[0016] The prepared samples were characterized by TEM, Raman spectroscopy and AFM, and the results were as follows: figure 1 , figure 2 and image 3 shown, from figure 1 It can be seen that at 1351.79cm -1 D peak appears at 1600.98cm -1 G peak appears at , which shows that the inventive method can prepare graphene; from figure 2 and image 3 It can be clearly seen that the prepared graphene has a gauze-like translucent sheet structure and a wrinkled surface.

[0017] Example 2

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com