Silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic and preparation method thereof

A silicon carbide fiber and composite material technology, applied in the field of radar absorbing ceramics, can solve the problems of difficult to achieve gradient distribution of dielectric properties, poor toughness of particle-reinforced ceramic materials, and difficulty in preparing large and complex components, so as to achieve good electromagnetic wave absorption function, Excellent mechanical properties, the effect of improving the interlaminar shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

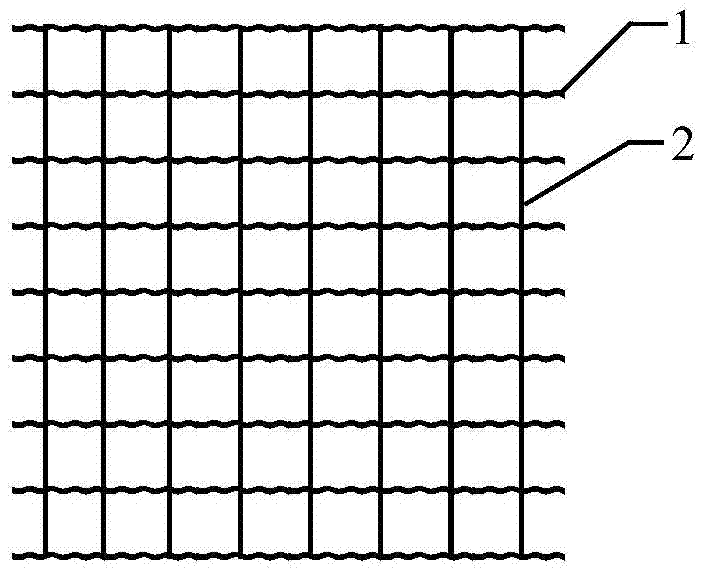

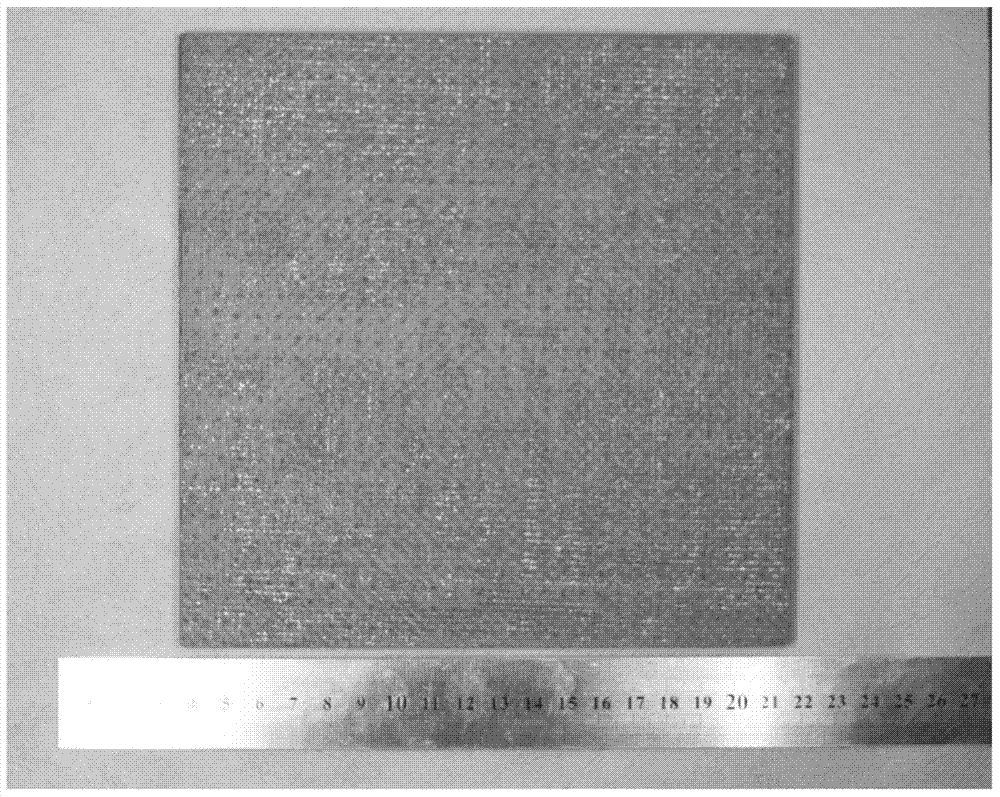

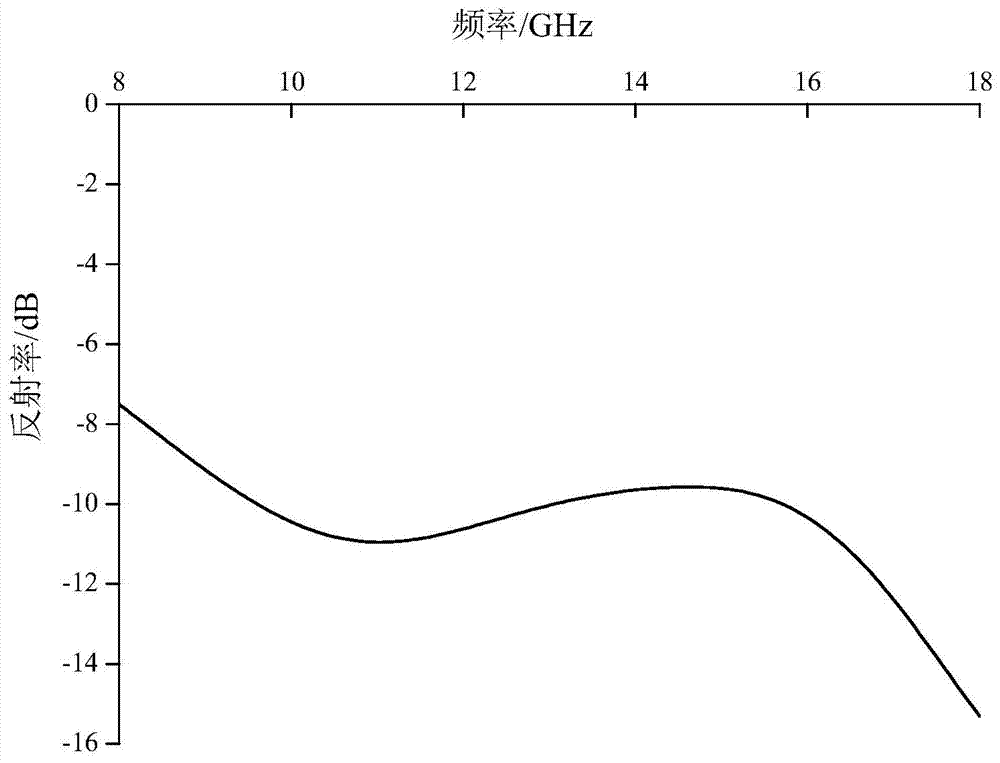

[0033] A silicon carbide fiber-reinforced silicon carbide composite wave-absorbing ceramic of the present invention, the wave-absorbing ceramic is a single-layer structure, and is mainly composed of continuous silicon carbide fiber-reinforced silicon carbide composite material, and the wave-absorbing ceramic is multi-layered Silicon carbide fiber plain weave is used as a reinforcement, and the multi-layered silicon carbide fiber plain weave is connected into a whole by carbon fiber Z-direction stitching, and the wave-absorbing ceramics are prepared by using the precursor impregnation and cracking process. The wave-absorbing ceramic has a bandwidth of 9.4 GHz with a reflectivity lower than -8dB in the frequency band of 8GHz to 18GHz at room temperature; the density of the wave-absorbing ceramic is 2.05g cm -3. The thickness of the wave-absorbing ceramics in the Z-direction sewing direction is 2.25mm. In this wave-absorbing ceramic, the resistivity of the continuous silicon car...

Embodiment 2

[0043] A silicon carbide fiber-reinforced silicon carbide composite wave-absorbing ceramic of the present invention, the wave-absorbing ceramic is a single-layer structure, and is mainly composed of continuous silicon carbide fiber-reinforced silicon carbide composite material, and the wave-absorbing ceramic is multi-layered The silicon carbide fiber plain weave is used as a reinforcement, and the multi-layered silicon carbide fiber plain weave is connected into a whole by carbon fiber Z-direction stitching, and the wave-absorbing ceramics are prepared by the precursor impregnation and cracking process. The bandwidth of the wave-absorbing ceramic with a reflectivity lower than -8dB in the frequency band of 8GHz to 18GHz at room temperature is 6.7GHz; the density of the wave-absorbing ceramic is 1.89g cm -3 . The thickness of the wave-absorbing ceramics in the Z-direction sewing direction is 2.5mm. The resistivity of the continuous silicon carbide fiber in the absorbing cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com