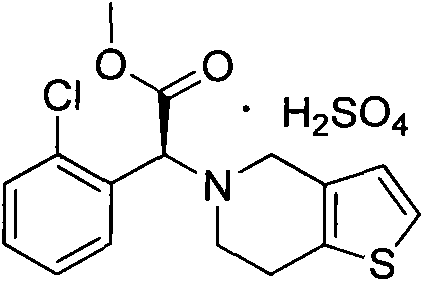

Method for refining clopidogrel hydrogen sulfate

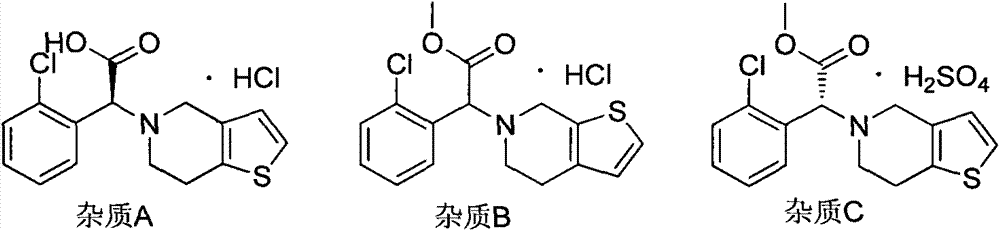

A technology of clopidogrel bisulfate and crude clopidogrel bisulfate, which is applied in the direction of organic chemistry, can solve the problems of cumbersome operation steps and unfavorable large-scale production, and achieve the effects of simple post-processing, convenient operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

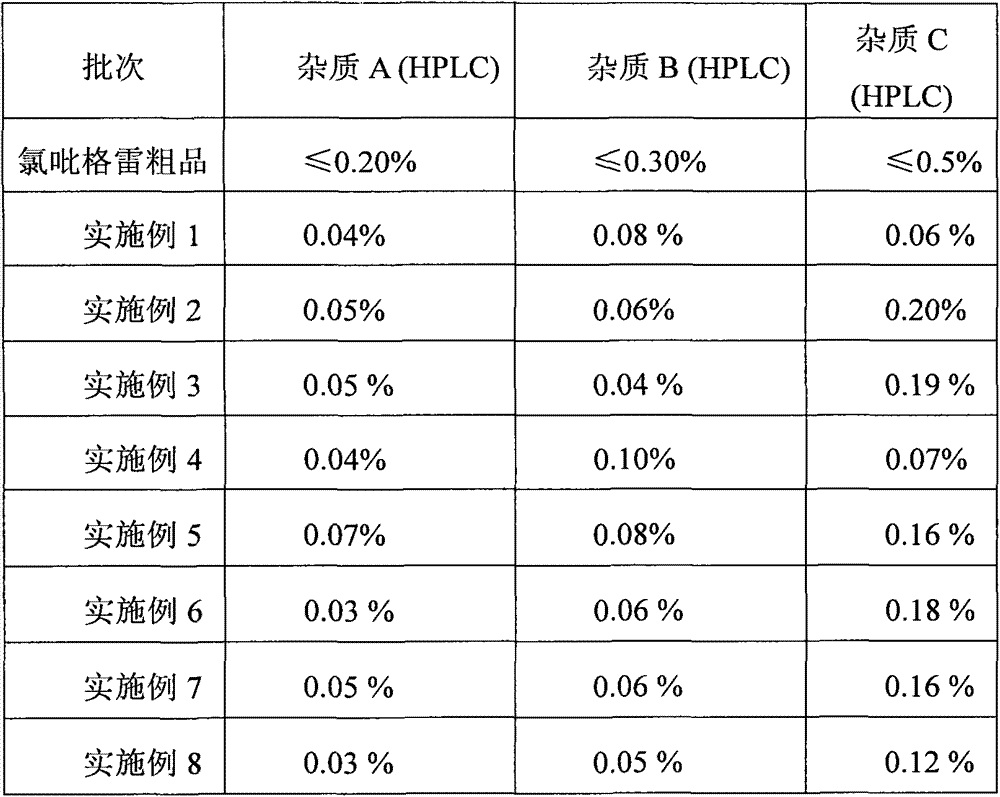

Examples

Embodiment 1

[0027] Example 1: 100 g of crude clopidogrel hydrogen sulfate, 10 g of methanol solution and 800 g of acetone solution were added together into a reaction flask, and then the reaction solution was heated to 20° C. After being completely dissolved, the temperature was slowly lowered to 15°C, and off-white crystals were precipitated. The crystals were slurried in acetone solution, filtered, and vacuum-dried at 30°C to obtain white crystals with a yield of 90%, a purity of 99.8%, and mp : 184~186℃, [α] D =55.0°.

Embodiment 2

[0028] Example 2: 100 g of crude clopidogrel hydrogen sulfate, 100 g of methanol solution and 100 g of ethyl acetate solution were added together into a reaction flask, and then the reaction solution was heated to 35°C. After complete dissolution, slowly lower the temperature to -15°C, precipitate off-white crystals, filter with suction, beat the crystals in ethyl acetate solution, filter, and then vacuum dry at 50°C to obtain white crystals with a yield of 87% , with a purity of 99.6%, mp: 184-186°C, [α] D =55.0°.

Embodiment 3

[0029] Example 3: 100 g of crude clopidogrel hydrogen sulfate, 20 g of methanol solution and 300 g of methyl tert-butyl ether solution were added into a reaction flask, and then the reaction solution was heated to 30°C. After completely dissolving, slowly lower the temperature to 5°C to precipitate off-white crystals, filter them with suction, beat the crystals in a solution of methyl tert-butyl ether, filter, and then dry them under vacuum at 60°C to obtain white crystals. 85%, purity 99.7%, mp: 184-186°C, [α] D =55.0°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com