Method for preparing ink capable of being used for preparing Cu2ZnSnS4 solar cell absorption layer film

A technology of solar cells and preparation methods, which is applied in the field of preparation of functional materials, can solve problems such as poor stability, poor safety, and restrictions on large-scale industrialization, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

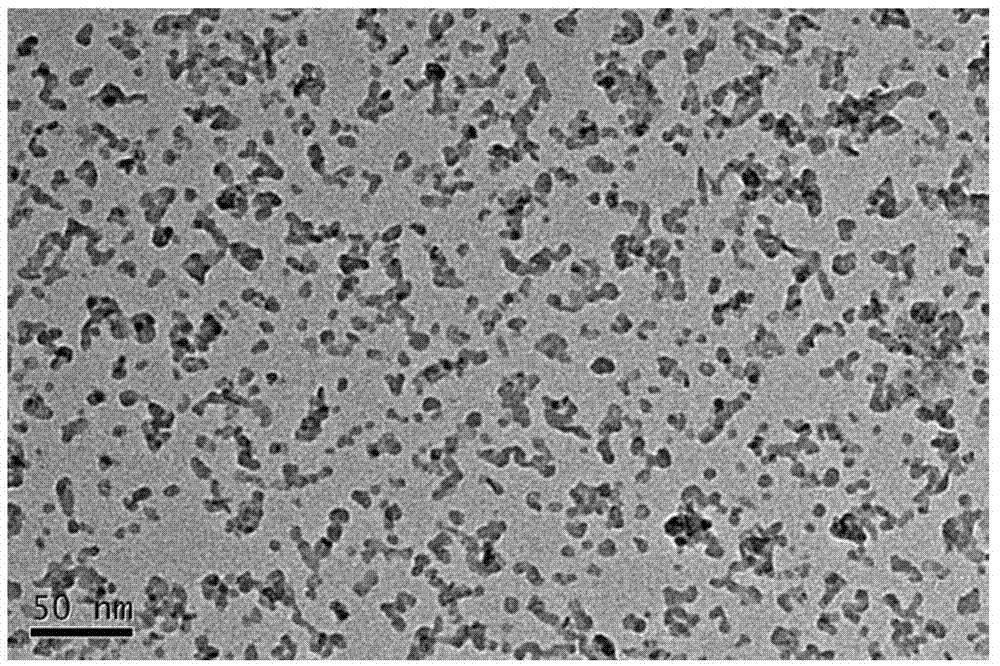

[0011] According to Cu:(Zn+Sn):S molar ratio 0.8:1:3, Zn:Sn molar ratio 1.2:1. First, dissolve copper chloride, zinc chloride, and tin chloride into 3ml dimethyl sulfoxide respectively, then mix the above three solutions together, then add the amount of dimethyl sulfoxide to 10ml, and fully Stir for 5 minutes, then add thioacetamide, stir fully at room temperature for 30 minutes, after it is completely dissolved, add ethanolamine solution drop by drop, stop adding when the color of the solution turns black, and the obtained black solution is the preparation ink.

[0012] The substantive features and remarkable advantages of the present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments, and the present invention is by no means limited to the stated embodiments.

[0013] 1). Weigh 1.0224g cupric chloride, 0.5571g zinc chloride, 0.7699g tin chloride.

[0014] 2). Take 3 vials and pour 3ml of dimethyl sulfoxide into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com