Water-soluble high-efficiency rare-earth luminescent material and preparation method thereof

A technology of rare earth luminescent and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of high efficiency, increased dissolved concentration, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

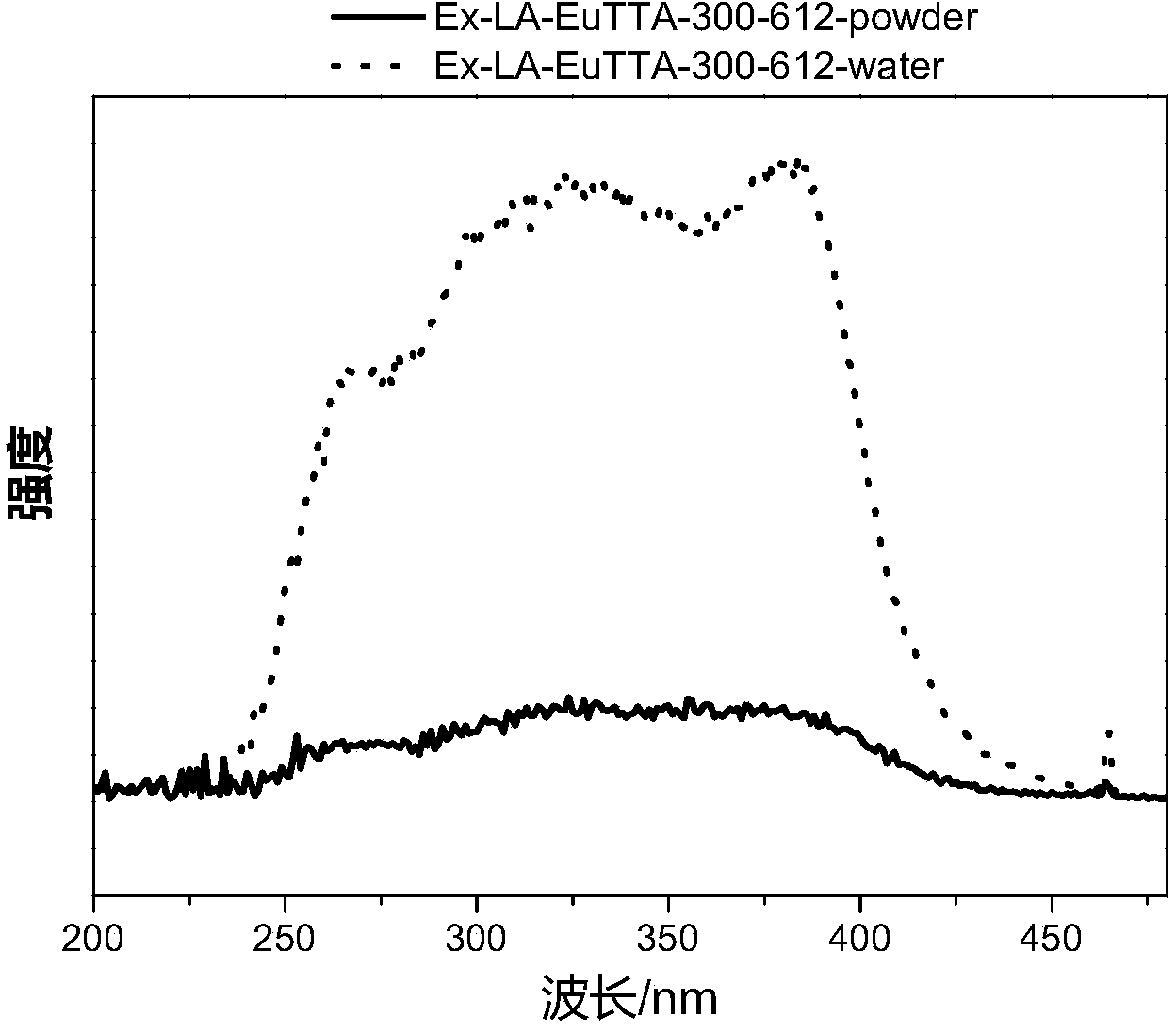

[0048] (1) Take 1g of laponite LAPONITE RD in a 100ml flask, add 15ml of double-distilled water to dissolve, ultrasonicate, and stir with a glass rod until it is in a transparent gel state (about 30min), then add 10ml of 0.1mol / L EuCl to it 3 ·6H 2 O ethanol solution, refluxed in an oil bath at 80°C for 24h. After centrifugation and drying, the ion-exchanged water-soluble gel-state nanoclay is obtained, which is designated as LA-Eu.

[0049] (2) Take 0.29g (1.308mmol,) α-thienoyltrifluoroacetone (TTA) in a 100ml flask (the molar number of Ln ions is excessive relative to TTA), add 10ml of absolute ethanol to dissolve, and then dissolve the condensate obtained in the previous step LA-Eu in the gel state was added to the flask, ultrasonicated, and then 6ml of absolute ethanol was added, reacted for 5 hours, centrifuged, and dried to obtain a water-soluble gel-state nanoclay containing luminescent rare earth organic ligands, which was designated as LA-EuTTA.

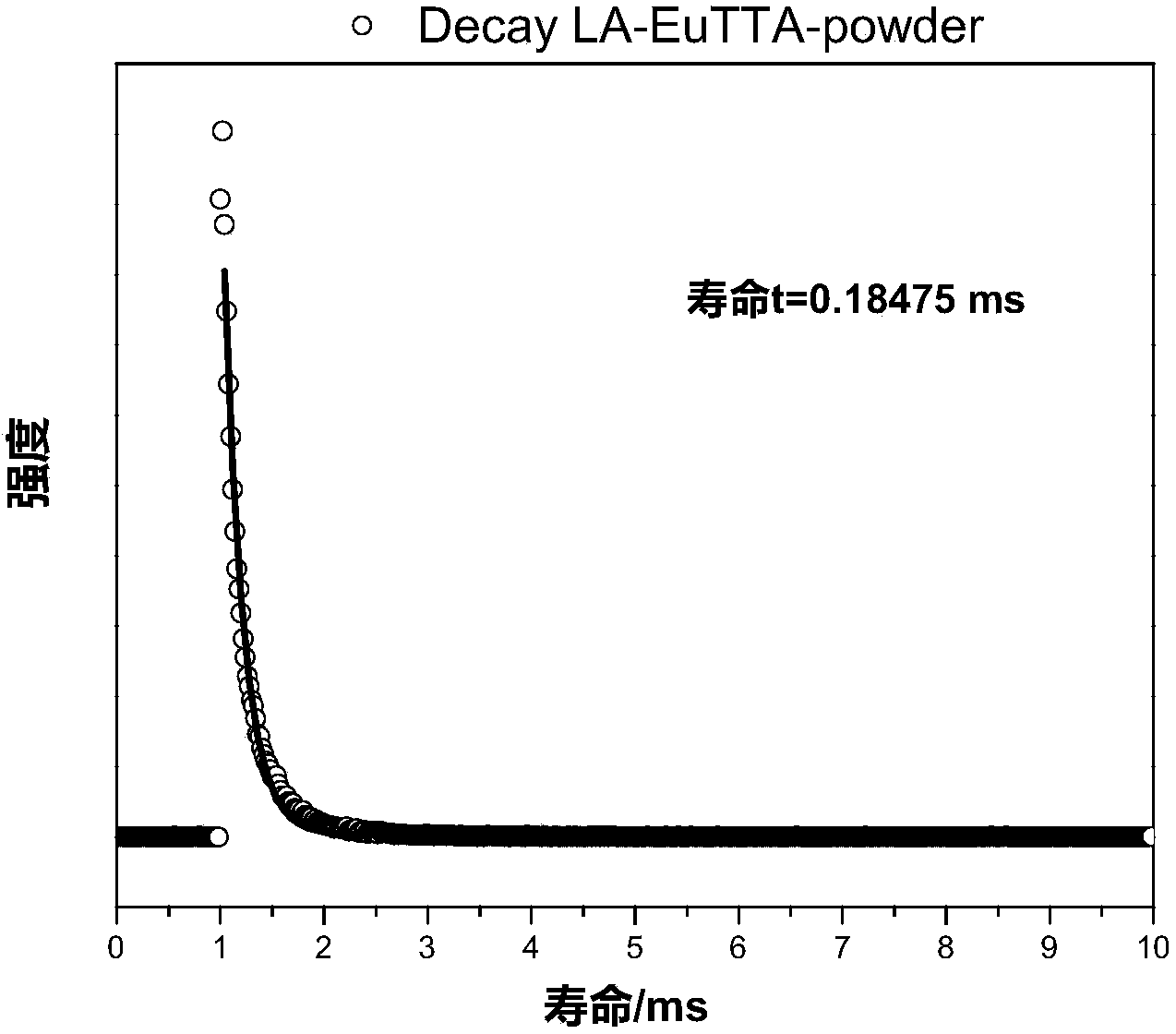

[0050] (3) Take t...

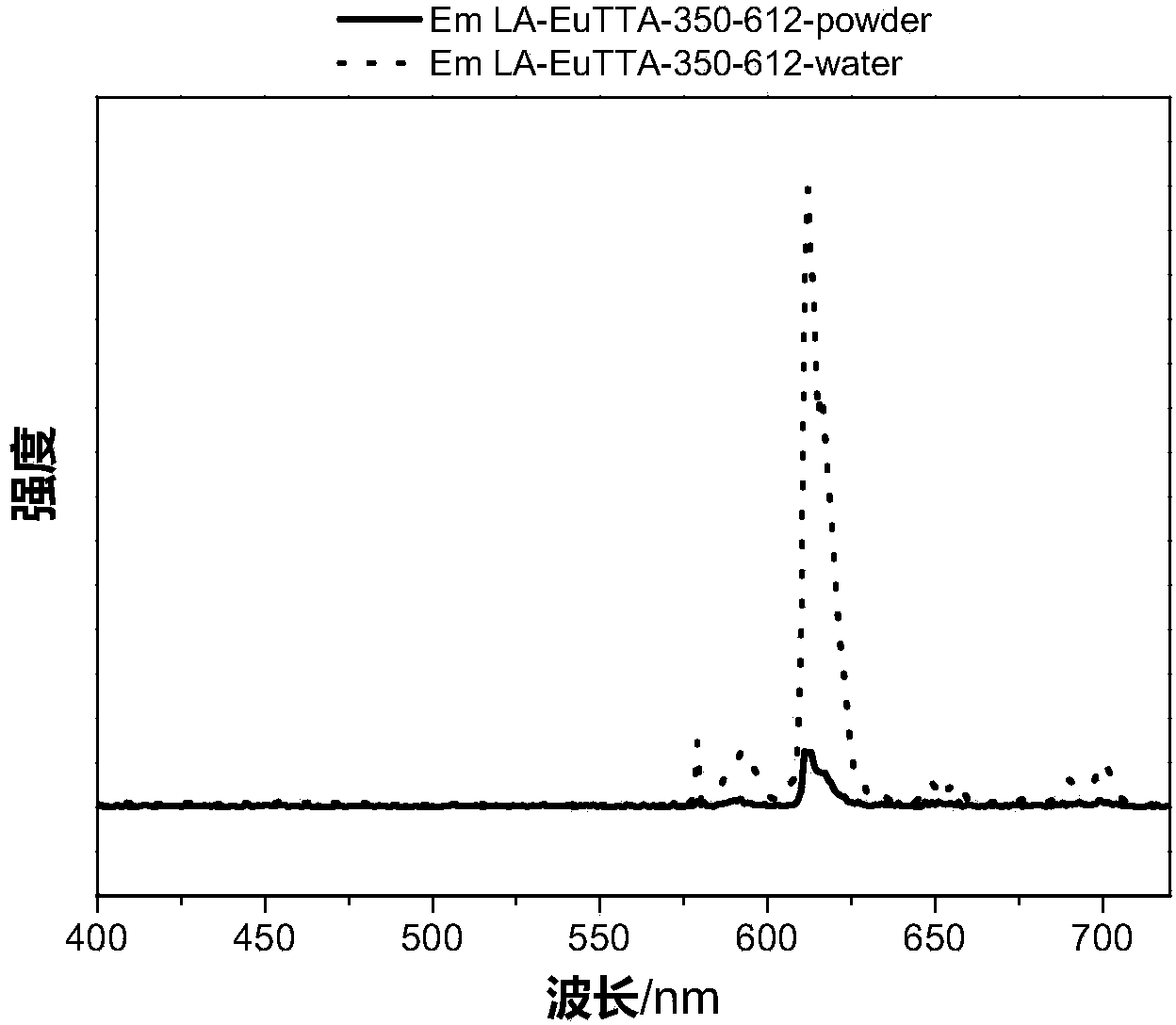

Embodiment 2

[0054] Steps (1) and (2) are the same as in Example 1, but the silanized ionic liquid II in steps (3) and (4) is changed to carboxylic acid ionic liquid VI, and other conditions remain unchanged, and finally water-soluble gel-state luminescence is obtained Material LA-EuTTA-VI. Under ultraviolet light, the luminescent material also exhibits a distinct bright red color. Compared with before modification with carboxylic acid ionic liquid, the luminescence lifetime is increased from 0.22ms to 0.50ms, the quantum efficiency is increased from 5.7% to 17.5%, and the fluorescence intensity at 612nm has also been greatly improved.

Embodiment 3

[0056] Steps (1) and (2) are the same as in Example 1, but the silanized ionic liquid II in steps (3) and (4) is changed to hydroxyl ionic liquid, and other conditions remain unchanged, and finally a water-soluble gel-state luminescent material LA is obtained. -EuTTA-VII. Under ultraviolet light, the luminescent material also exhibits a distinct bright red color. Compared with before modification with hydroxyl ionic liquid, the luminescence lifetime is increased from 0.22ms to 0.51ms, the quantum efficiency is increased from 5.7% to 18.3%, and the fluorescence intensity at 612nm has also been greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com