Basalt fiber and polyvinyl alcohol combined anti-erosion construction protection method for silt slope

A technology of basalt fiber and polyvinyl alcohol, applied in botany equipment and methods, excavation, infrastructure engineering, etc., can solve the problems of pollution impact, non-compliance with environmental protection requirements, non-compliance with green requirements, etc., to improve tensile and anti-corrosion Shear strength, easy large-scale application and popularization, and the effect of reducing erosion and infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

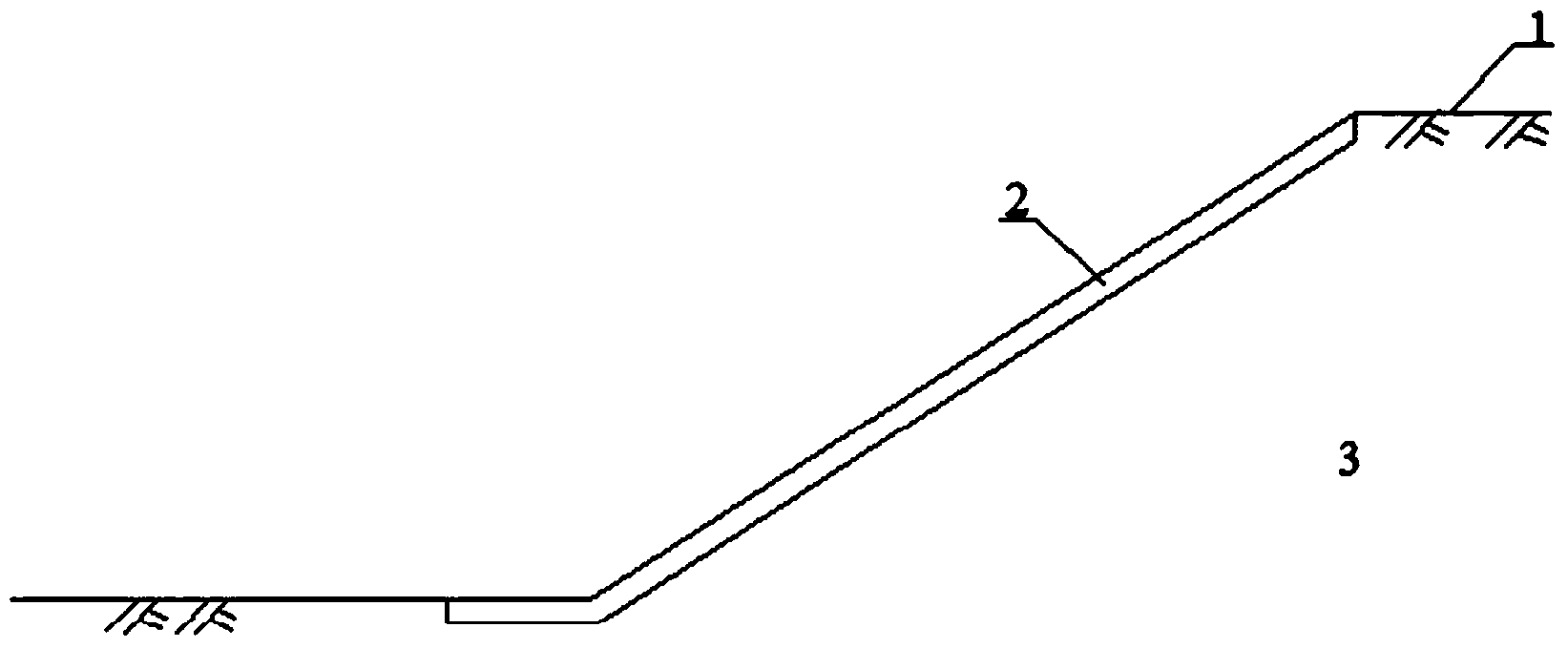

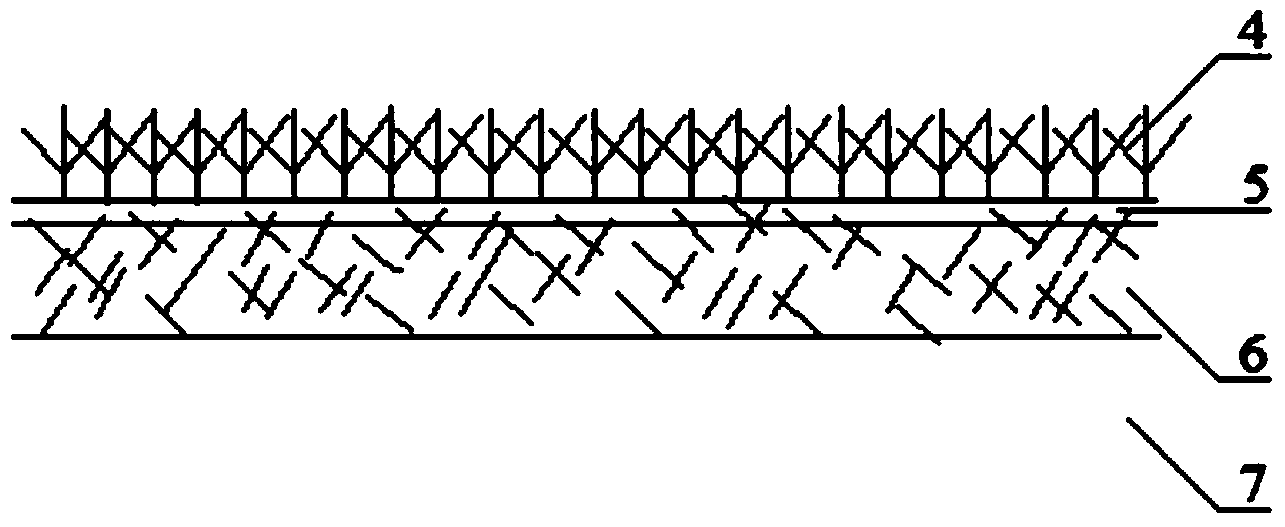

[0027] Attached below figure 1 The technical scheme of the present invention is described in detail:

[0028] The basalt fiber and polyvinyl alcohol combined anti-scouring protection technology and construction method of the silt slope mainly include two parts: design and construction. The specific steps are as follows:

[0029] A basalt fiber and polyvinyl alcohol combined anti-scouring protection construction method for silt slopes is characterized in that the method includes two parts, design and construction, and the specific steps are as follows:

[0030] Step 1: Collect rainfall observation data from meteorological stations in the project area for more than 10 years, and calculate the average rainfall intensity within the design return period and rainfall duration according to Article 9.1.6 of "Code for Design of Highway Drainage JTG / T D33-2012"; If there is no rainfall observation data, the rainfall intensity can be calculated according to Article 9.1.7 of "Code for De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com