Detection method for oxidable contaminant in aqueous sample

A pollutant and sample technology, applied in the field of chemical analysis, can solve problems affecting measurement results, signal deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

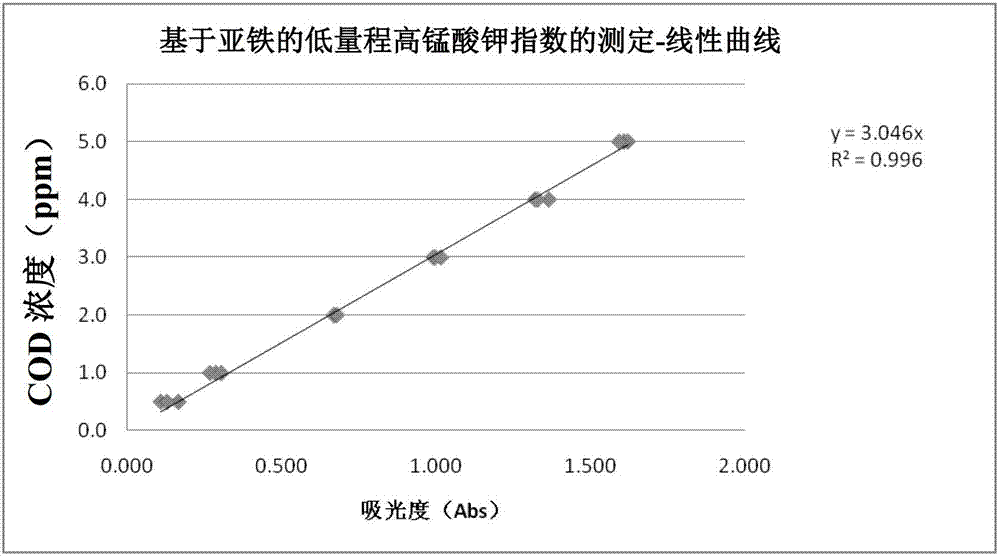

[0103] Embodiment 1: Determination of the potassium permanganate index based on the low range of ferrous iron

[0104] Reagent: 1:3 sulfuric acid, slowly add 1 part of 96%-98% sulfuric acid to 3 parts of water, cool and set aside; 2mmol / L potassium permanganate solution; 10mmol / L ferrous ammonium sulfate solution; indication The agent is 1.222g / L o-phenanthroline solution.

[0105] COD standard sample: Gradiently dilute the 208ppm COD standard sample (GBW(E)080274) purchased from the National Standards Center to 5.0ppm, 4.0ppm, 3.0ppm, 2.0ppm, 0.5ppm for later use. The COD standard contains glucose as oxidizable. Detection steps:

[0106] 1. Add 5mL COD standard sample into a 16mm diameter glass digestion tube that has been prefilled with 0.25mL 1:3 sulfuric acid;

[0107] 2. Add 0.5mL 2mmol / L potassium permanganate solution, cover and mix well;

[0108] 3. Digest in a preheated 100-degree digester DRB200 for half an hour;

[0109] 4. Immediately after digestion, take o...

Embodiment 2

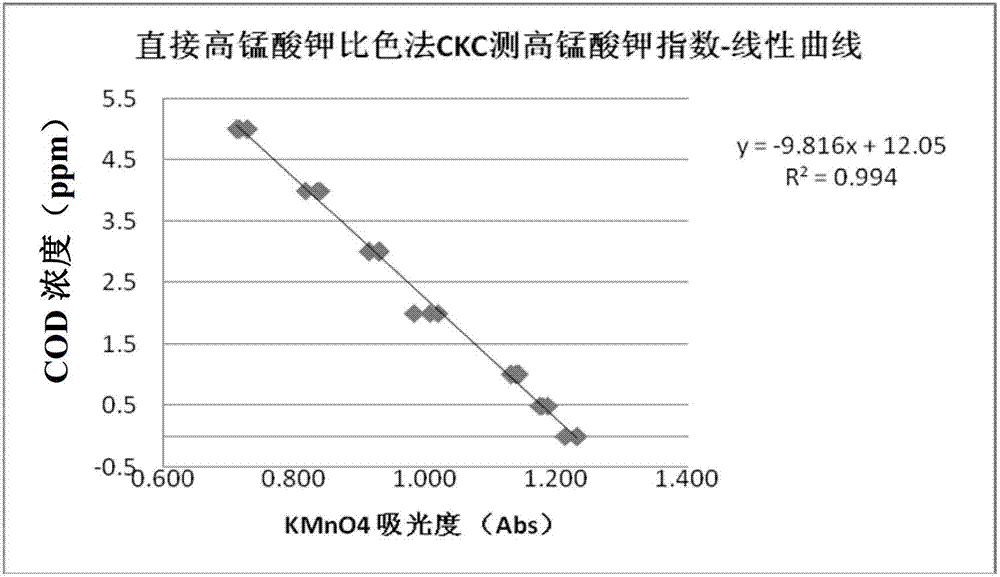

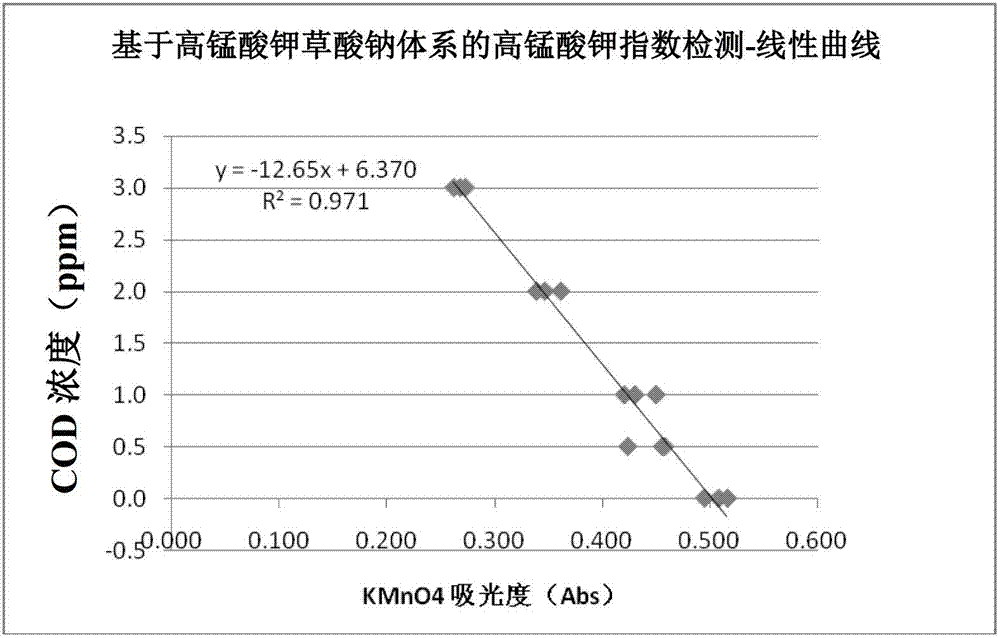

[0115] Embodiment 2: the comparison of the method for measuring potassium permanganate index of the present invention and other two kinds of absorbance detection methods

[0116] This embodiment compares the absorbance detection method based on the reducing agent of the present invention and two other absorbance detection methods based on potassium permanganate, namely the method of Central Kagaku Company (CKC) in Japan and the LCK 394 TNT of Lange (Lange) in Germany plus vial method. The method of Japan CKC Company is to completely react the water sample with quantitative permanganate, and then directly measure the absorbance of the residual permanganate, while the method of German Lange (Lange) is to first use the water sample with permanganate Oxidation, the residual permanganate is reduced with sodium oxalate, then the residual sodium oxalate is oxidized with a quantitative permanganate standard solution, and finally the absorbance of the residual permanganate after reac...

Embodiment 3

[0143] Embodiment 3: Determination of high range potassium permanganate index based on ferrous iron

[0144] The method of the present invention is also applicable to the determination of the potassium permanganate index in a high range.

[0145] Reagent: 1:3 sulfuric acid, slowly add 1 part of 96-98% concentrated sulfuric acid to 3 parts of water, cool and set aside; 6mmol / L potassium permanganate solution; 12mmol / L ferrous ammonium sulfate solution; The indicator is 1.222g / L o-phenanthroline solution.

[0146] COD standard sample: gradiently dilute the 208ppm COD standard sample (GBW(E)080274) purchased from the National Standards Center to 15.0ppm, 14.0ppm, 13.0ppm, 12.0ppm, 10ppm, 9.0ppm, 8.0ppm, 7.0ppm , 6.0ppm, 5.0ppm, 4.0ppm, 3.0ppm standby. The COD standard contains glucose as oxidizable.

[0147] Detection steps:

[0148] 1. Add 5mL COD standard sample into a 16mm diameter glass digestion tube that has been prefilled with 0.75mL 1:3 sulfuric acid;

[0149] 2. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com