Thermally-operated conversion system

A conversion system and intermediate heat exchanger technology, applied in the field of thermal-dynamic conversion system, can solve the problems of complex system, poor thermal conductivity of lead, high power density, etc., and achieve the effects of system safety and reliability, good thermal conductivity and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

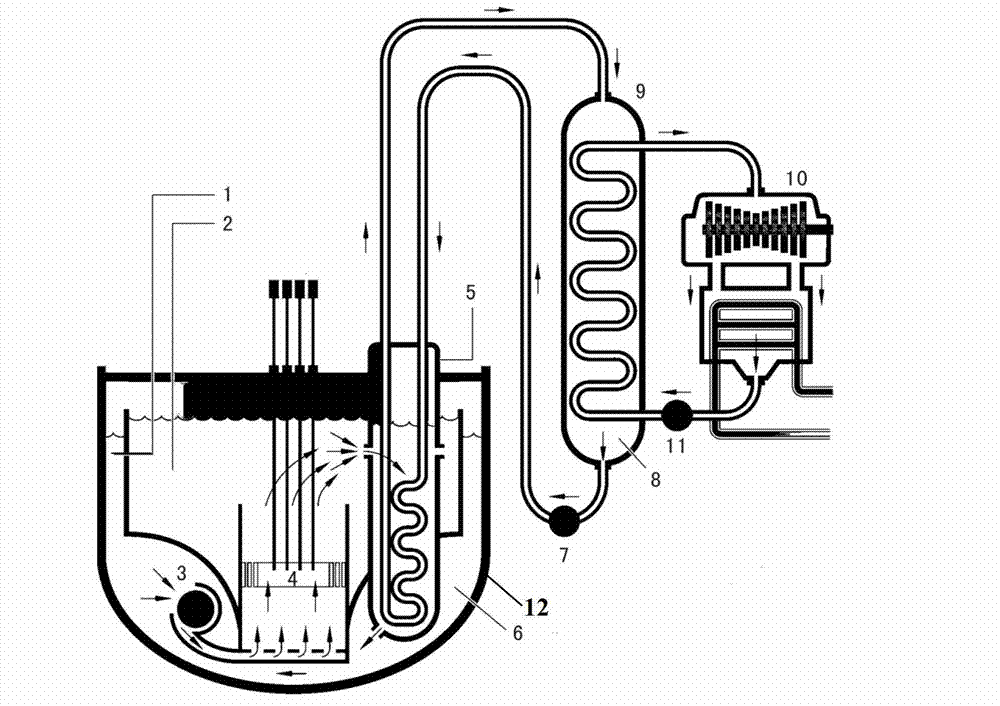

[0025] Such as figure 1 As shown, a thermal conversion system of the present invention includes three loops, and the first loop includes a cold pool 1, a main pump 3, a core 4, a hot pool 2, and an intermediate heat exchanger arranged in the main container 12 and connected sequentially. 5. The second circuit includes the secondary circuit circulation pump 7, intermediate heat exchanger 5, and steam generator 9 connected in sequence; the third circuit includes the feed water pump 11, steam generator 9, and steam turbine 10 connected in sequence; the working medium of the primary circuit is liquid metal Sodium 6, the working medium of the secondary circuit is liquid metal lead or lead-bismuth alloy 8, and the third circuit is a traditional water-steam circuit;

[0026] The specific heat transfer process of the thermal conversion system is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com