Adhesive composition, adhesive layer, polarizing film having adhesive layer, and image formation device

A technology of adhesive layer and composition, which is applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., and can solve liquid crystal display device liquid crystal orientation effects, small static electricity generation, uneven display, etc. Problems, achieve excellent antistatic function, improve durability, and prevent unevenness after heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

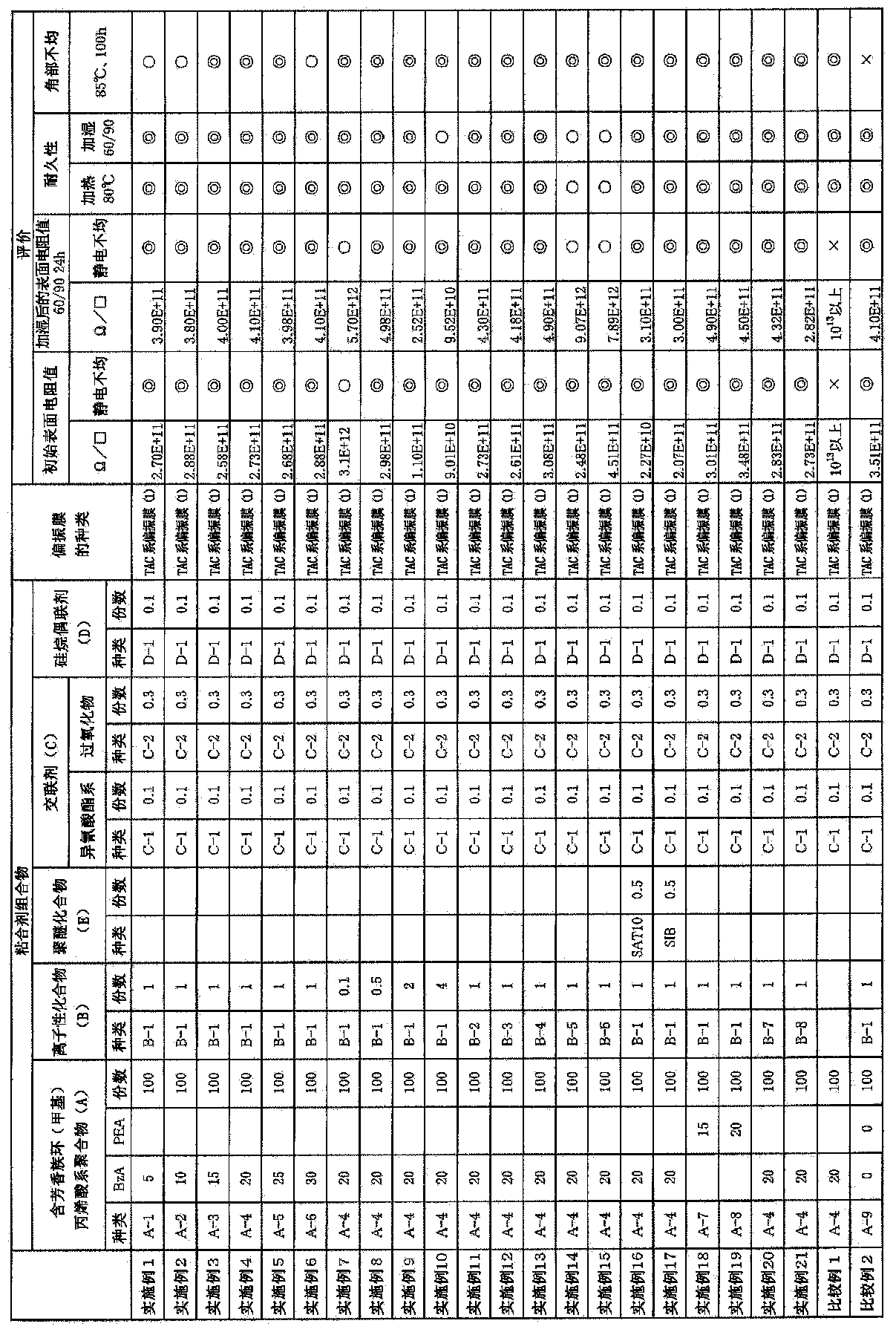

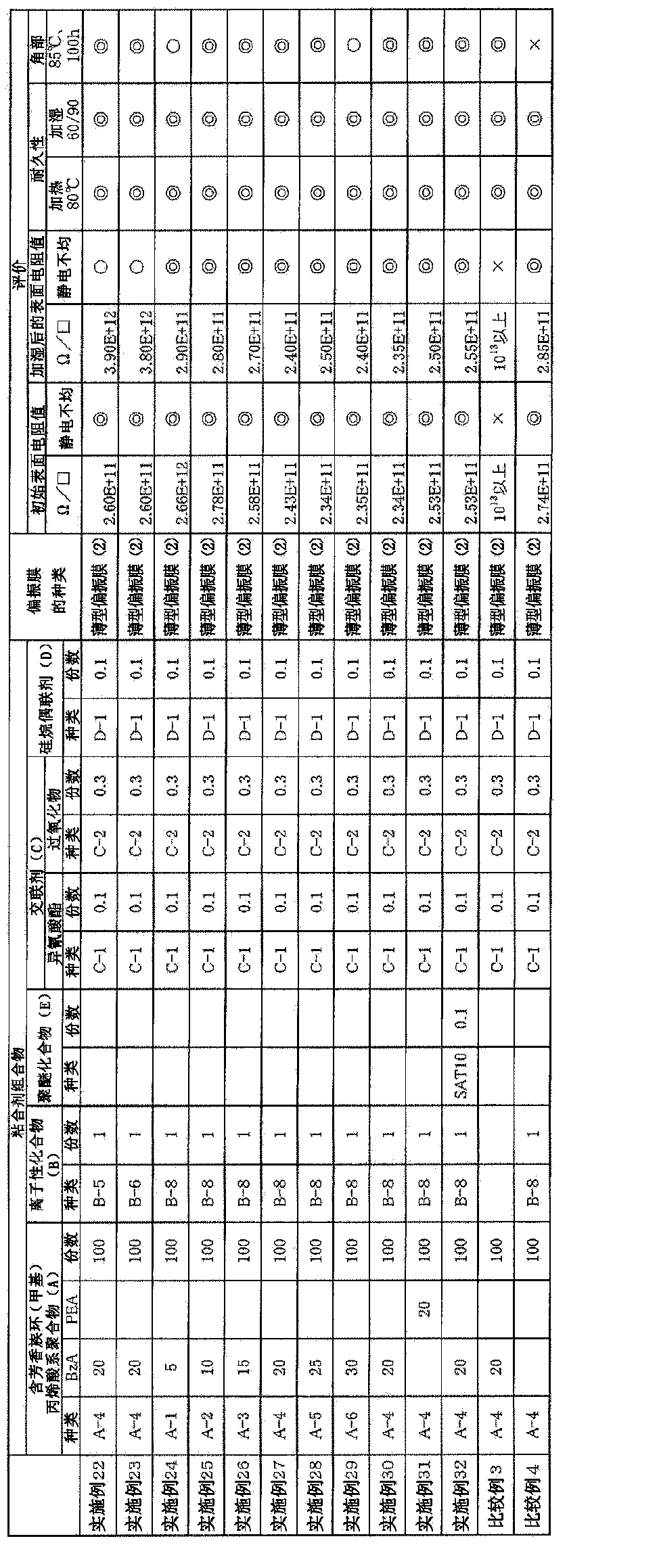

[0161] The following examples illustrate the present invention in detail, but the present invention is not limited by these examples. In addition, the parts and % in each example are based on weight.

[0162]

[0163] The weight-average molecular weight of the aromatic ring-containing (meth)acrylic polymer (A) is measured by GPC (gel permeation chromatography).

[0164] ・Analyzer: HLC-8120GPC manufactured by Tosoh Corporation

[0165] ・Pillar: Made by Tosoh Corporation, G7000H XL +GMH XL +GMH XL

[0166] · Column size: each Total 90cm

[0167] ·Column temperature: 40℃

[0168] ·Flow: 0.8ml / min

[0169] ·Injection volume: 100μl

[0170] ·Eluent: tetrahydrofuran

[0171] Detector: Differential refractometer (RI)

[0172] ·Standard sample: polystyrene

[0173]

[0174] A polyvinyl alcohol film having a thickness of 80 μm was stretched 3 times while being dyed in a 0.3% iodine solution at 30° C. for 1 minute between rollers having different speed ratios. Then, wh...

manufacture example 1

[0180]

[0181] In a reaction vessel equipped with a condenser tube, a nitrogen introduction tube, a thermometer, and a stirring device, 90 parts of butyl acrylate, 5 parts of benzyl acrylate (BzA), 5 parts of 4-hydroxybutyl acrylate, and a relative 100 parts of the monomer (solid state) is 1 part of AIBN as an initiator, and it is reacted at 60° C. for 7 hours under a nitrogen stream, and then ethyl acetate is added to the reaction solution to obtain a compound with a weight average molecular weight of 120. Wan's solution (solid content concentration: 30% by weight) of an aromatic ring-containing (meth)acrylic polymer (A-1).

manufacture example 2

[0183]

[0184] As the monomer mixture in Production Example 1, a monomer mixture containing 87 parts of butyl acrylate, 10 parts of benzyl acrylate, and 3 parts of 4-hydroxybutyl acrylate was used, and the same operation as in Production Example 1 was carried out, A solution of an aromatic ring-containing (meth)acrylic polymer (A-2) having a weight average molecular weight of 1.3 million was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com