Reaction kettle type heating system for heat transfer reaction of material in chemical industry

A heating system and thermal reaction technology, applied in chemical/physical/physical chemical fixed reactors, chemical/physical processes, feeding devices, etc., can solve the problem that the production rate of aluminum sulfate or aluminum ammonium sulfate is not high and cannot meet the requirements of roasting Time requirements, high requirements for equipment corrosion resistance, etc., to achieve the effect of low raw material processing requirements, controllable reaction time, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

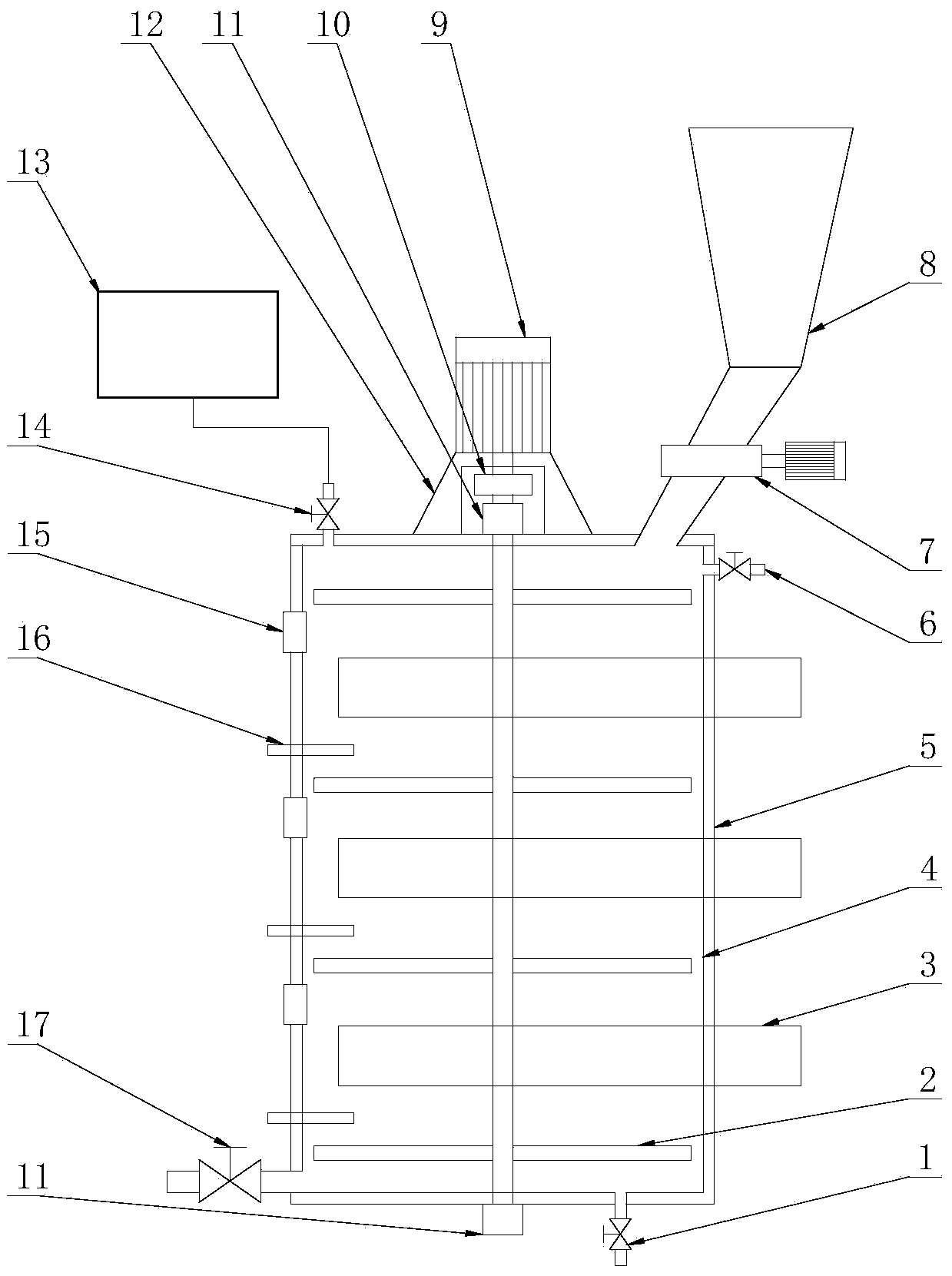

[0026] Such as figure 1 As shown, the present invention is a reactor type heating system used for material heat exchange reactions in the chemical industry, which mainly includes a reactor body 4 and its internal layered heating device 3, stirring device 2 and temperature measuring device 16, and at the same time It also includes a sewage discharge device 1 and a discharge device 17 at the bottom or bottom of the reactor body 4, an aeration and distributing device 6, an absorption or recovery device 13, a feeding device 7, a raw material warehouse 8, etc., and a reactor body 4 Side peeping device 15 etc.

[0027] Among them, the heating device 3 and the stirring device 2 are arranged at intervals to make the temperature in the reactor uniform. The heating device 3 is a heat-conducting oil heating device, which is composed of a coil and is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com