A method for preparing hydrophobic sio2 aerogel by drying under normal pressure

An atmospheric drying, hydrophobic technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of solvent waste, restricting practical application value, low integrity of aerogel blocks, etc., achieving good block integrity, The effect of low cost and uncomplicated experimental environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

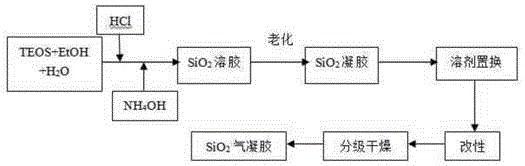

Method used

Image

Examples

Embodiment 1

[0032] Mix 10ml tetraethyl orthosilicate, 4.0ml deionized water, and 18.0ml absolute ethanol, then add hydrochloric acid (1mol / L) to adjust the pH value between 3 and 4, and fully stir the mixed solution at room temperature for 30min , and then add ammonia water (0.1 mol / L) to adjust the pH value between 6 and 8. Put the solution into an airtight container to form a gel, and then age it in absolute ethanol at about 20°C for one day. Add n-hexane to the aged gel for solvent replacement for 12 hours, and replace the ethanol and excess water in the pores. Pour off the remaining n-hexane, add n-hexane modification solution with a volume concentration of 8% TMCS, and carry out surface modification at 50°C for 12h. Then the gel was washed with n-hexane at 50 °C for 8 h. Finally, after drying, the hydrophobic SiO 2 airgel.

[0033] The drying process is as follows: the gel samples are dried at 60°C, 80°C, 100°C, 120°C, and 150°C for 1.5 hours respectively, and then cooled to room...

Embodiment 2

[0037] Mix 10ml of tetraethyl orthosilicate, 4.0ml of deionized water, and 16.0ml of absolute ethanol, then add hydrochloric acid (1mol / L) to adjust the pH value between 3 and 4, and fully stir the mixed solution at room temperature for 30min , and then add ammonia water (0.1 mol / L) to adjust the pH value between 6 and 8. Place the solution in an airtight container to form a gel. Then aged at about 20°C for one day, and selected TEOS / absolute ethanol with a volume ratio of 1:4 as the aging solution. Add n-hexane to the aged gel for solvent replacement for 12 hours, and replace the ethanol and excess water in the pores. Pour off the remaining n-hexane, add n-hexane modification solution with a volume concentration of 12% HMDZ, and modify the surface of the gel at 50°C for 12 hours. Then the gel was washed with n-hexane at 50 °C for 8 h. Finally, after drying, the hydrophobic SiO 2 airgel.

[0038] The drying process is as follows: the gel samples are dried at 50°C, 70°C, 9...

Embodiment 3

[0041] Mix 10ml tetraethyl orthosilicate, 3.5ml deionized water, and 20.0ml absolute ethanol, then add oxalic acid (0.1mol / L) to adjust the pH value between 3 and 4, and stir the mixed solution fully at room temperature After 1 h, aqueous ammonia (0.01 mol / L) was added to adjust the pH value between 6 and 8. Put the solution in an airtight container to form a gel, and then at about 20°C in H with a volume ratio of 1:1.5 2 Aged in O / absolute ethanol for two days. Add n-hexane to the aged gel for solvent replacement for 24 hours to replace excess solvent. Pour off the remaining n-hexane, add n-hexane modification solution with a volume concentration of 10% TMCS, and carry out surface modification at 60°C for 12 hours. Then the gel was washed with n-hexane at 60°C for 10 h. Finally, after drying, the hydrophobic SiO 2 airgel.

[0042] The drying process is as follows: the gel samples are dried at 60°C, 80°C, 100°C, 120°C, and 150°C for 2 hours respectively, and then cooled t...

PUM

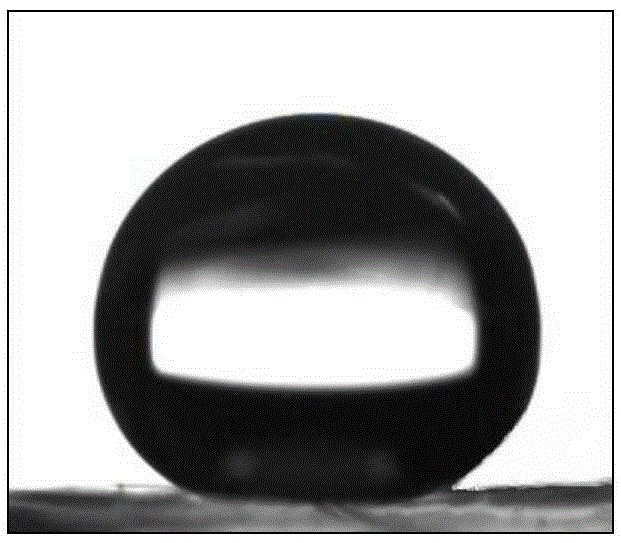

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com