Process for treating landfill leachate through Fenton method and supercritical water oxidation method

A supercritical water oxidation and landfill leachate technology, applied in the field of environmental science, can solve the problems of high power consumption, difficulty in large-scale industrial application, and high requirements for reactor materials, and achieve cost saving, appropriate cost, and thorough treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

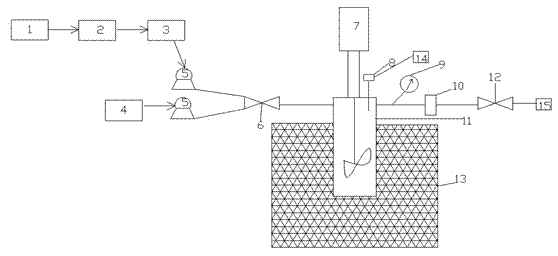

Method used

Image

Examples

Embodiment 1

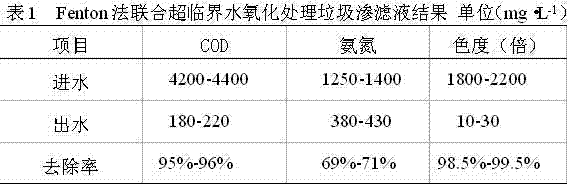

[0015] Embodiment 1 of the present invention: Fenton method combines supercritical water oxidation method to process landfill leachate, comprises the following steps:

[0016] 1) Landfill leachate with COD of 2000-30000mg / L and salinity less than 5%, adjust the pH of the landfill leachate to 4, add hydrogen peroxide and ferrous sulfate, the molar ratio of hydrogen peroxide and ferrous sulfate is 4:1, Use the Fenton method to pretreat the landfill leachate, react for 2 hours, adjust the pH to 8 to terminate the reaction, and let it settle for 1 hour;

[0017] 2) Take the supernatant after static precipitation in step 1) and enter the supercritical water oxidation system, using copper nitrate as the catalyst, after adding copper nitrate, Cu 2+ The concentration is 45mg·L -1 , Hydrogen peroxide is added to the reactor according to 3 times the theoretical oxygen demand of the landfill leachate, and the temperature is controlled at 440°C and the pressure is 26MPa to react for 4 mi...

Embodiment 2

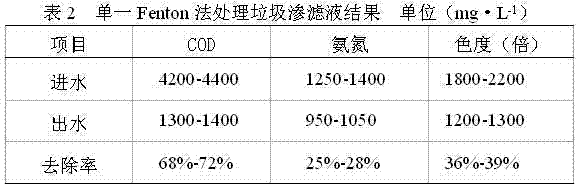

[0021] Embodiment 2: the Fenton process of landfill leachate, reaction condition: pH=4, n (H 2 o 2 ): n (Fe 2+ )=4:1, the reaction time is 2h, the results are shown in Table 2:

[0022]

Embodiment 3

[0023] Example 3: Supercritical water oxidation treatment of landfill leachate, reaction conditions: temperature 500°C, pressure 26 MPa, oxidant ratio K 3.0, copper ion concentration 45 mg L -1 , the results are shown in Table 2:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com