A continuous tower reactor for thermal hydrolysis treatment of sludge

A tower reactor, thermal hydrolysis technology, applied in pyrolysis treatment of sludge, dissolution, chemical instruments and methods, etc., can solve the problems of poor stability, long time, complicated operation, etc., to ensure the reaction time, improve the Stirring efficiency and heat transfer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

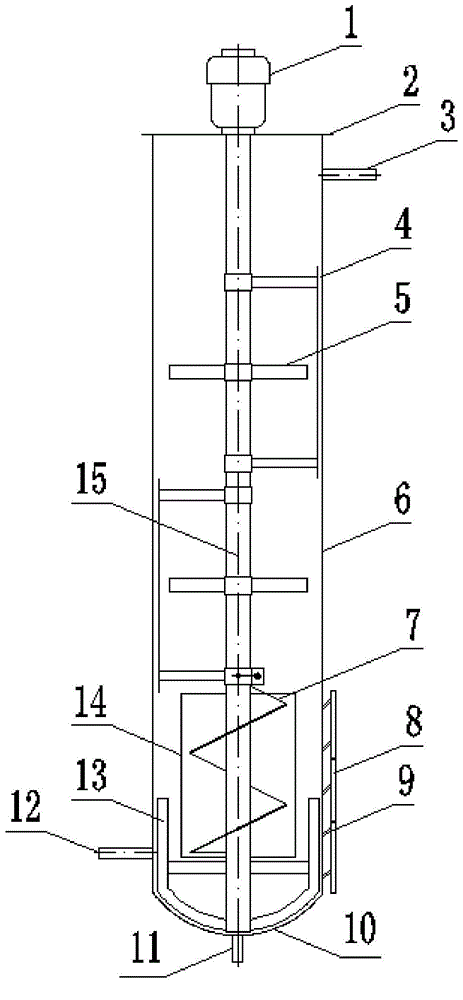

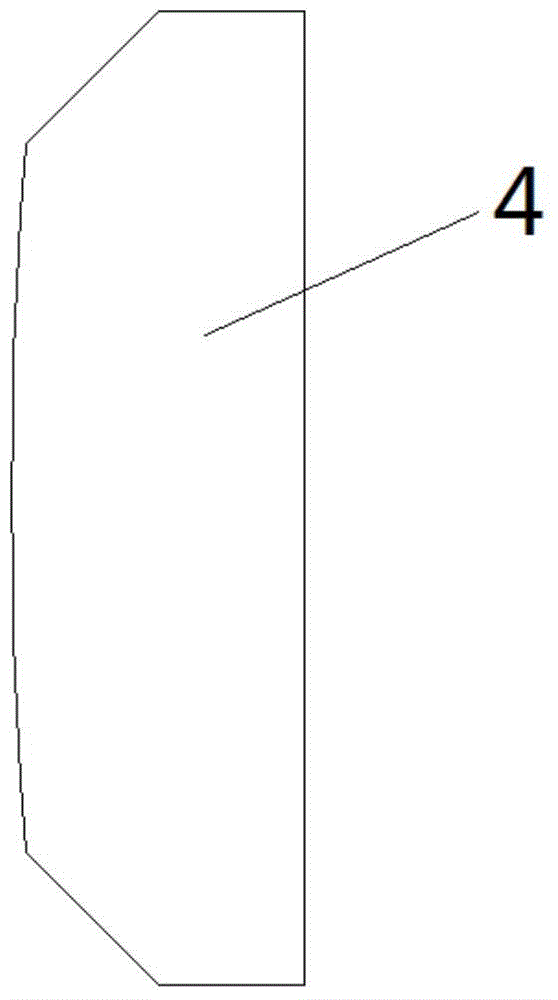

[0023] Such as figure 1 As shown, a continuous tower reactor for sludge thermal hydrolysis treatment includes a cylinder 6 with a top cover 2 at the top and a head 10 at the bottom, and a stirring shaft arranged on the axis of the cylinder 6 15. The stirring shaft 15 is connected to the stirring motor 1 on the upper part of the top cover 2, and the stirring shaft 15 is sequentially provided with an anchor stirrer 13, a screw stirrer 7 and at least one paddle stirrer that fits the reactor head 10 profile from bottom to top. The agitator 5 and the screw agitator 7 are provided with a screw agitator sleeve 14 used in conjunction with it, and the paddle agitator 5 is provided with a near-wall rotary scraper 4 that fits the inner wall of the cylinder body 6. There are edges and corners on both sides, and the bottom end of the cylinder body 6 is provided with a sewage disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com