Hydrophobic gas-phase SiO2 nano-pore heat-insulating material and preparation method thereof

A thermal insulation material, hydrophobic technology, applied in the field of hydrophobic gas phase SiO2 nanoporous thermal insulation material and its preparation, can solve the problem of increased dielectric constant of gas phase silica, inconvenient material storage, transportation and handling, collapse of nanoporous structure and thermal insulation effect and other problems, to achieve the effect of low physiological inertia, excellent mechanical properties, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

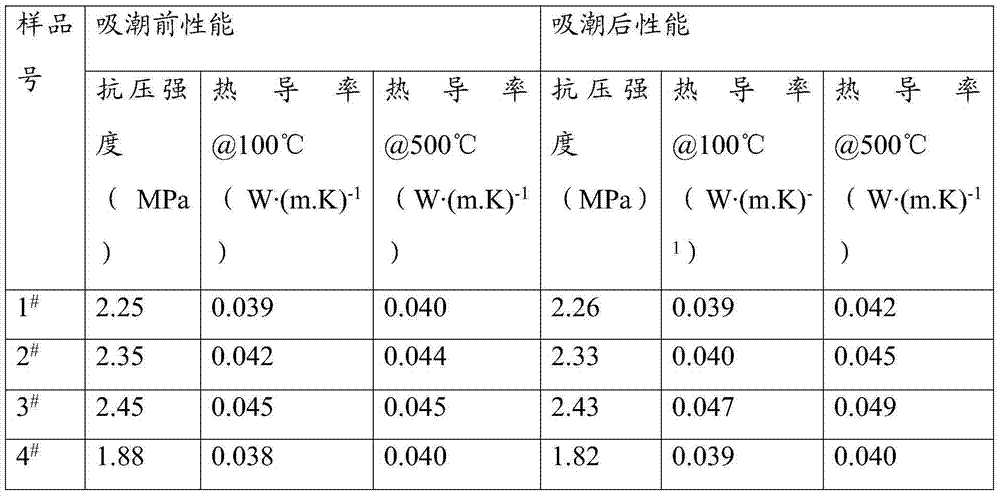

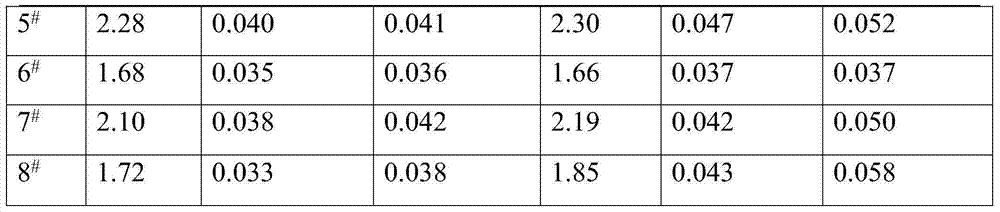

Examples

Embodiment 1

[0039] In this embodiment, a kind of hydrophobic gas phase SiO 2 Nanoporous thermal insulation material, prepared from the following raw material components: 75wt% hydrophobic gas phase SiO 2 , 7wt% pretreated glass fiber, 13wt% infrared shielding agent and 5wt% inorganic binder (calcined kaolin: wollastonite powder: sodium silicate: diatomaceous earth at a mass ratio of 1:2:1:1.5).

[0040] The above-mentioned hydrophobic gas phase SiO 2 A method for preparing a nanoporous heat insulating material, comprising the steps of:

[0041] (1) Gas-phase SiO 2 Put it in the reactor and stir, the stirring speed is 600r / min, and the temperature is 200°C. After stirring for 1h, add the surface treatment agent into the reactor in a spray state, adjust the stirring speed to 750r / min, and conduct heat treatment at 200°C for 4h to obtain hydrophobicity. Vapor SiO 2 (Carbon content up to 4.5%);

[0042] Among them, gas phase SiO 2 The mass ratio with the surface treatment agent is 89:11...

Embodiment 2

[0047] In this embodiment, a kind of hydrophobic gas phase SiO 2 Nanoporous thermal insulation material, prepared from the following raw material components: 65wt% hydrophobic gas phase SiO 2 , 10wt% pretreated glass fiber, 15wt% infrared shielding agent and 10wt% inorganic binder (calcined kaolin: wollastonite powder: sodium silicate: diatomaceous earth at a mass ratio of 1:2:1:1.5).

[0048] The above-mentioned hydrophobic gas phase SiO 2 A method for preparing a nanoporous heat insulating material, comprising the steps of:

[0049] (1) Gas-phase SiO 2 Put it in the reactor and stir at a stirring speed of 500r / min and a temperature of 300°C. After stirring for 1 hour, add the surface treatment agent into the reactor in a spray state, adjust the stirring speed to 650r / min, and conduct heat treatment at 220°C for 3 hours to obtain hydrophobicity. Vapor SiO 2 (Carbon content up to 3.2%);

[0050] Among them, gas phase SiO 2 The mass ratio of surface treatment agent is 90:...

Embodiment 3

[0055] In this embodiment, a kind of hydrophobic gas phase SiO 2 Nanoporous thermal insulation material, prepared from the following raw material components: 80wt% hydrophobic gas phase SiO 2 , 5wt% pretreated glass fiber, 10wt% infrared shielding agent and 5wt% inorganic binder (calcined kaolin: wollastonite powder: sodium silicate: diatomaceous earth at a mass ratio of 1:2:1:1.5).

[0056] The above-mentioned hydrophobic gas phase SiO 2 A method for preparing a nanoporous heat insulating material, comprising the steps of:

[0057] (1) Gas-phase SiO 2 Place in the reactor and stir at a stirring speed of 500r / min and a temperature of 120°C. After stirring for 1 hour, add the surface treatment agent into the reactor in a spray state, adjust the stirring speed to 600r / min, and conduct heat treatment at 200°C for 3 hours to obtain hydrophobicity. Vapor SiO 2 (Carbon content reaches 4.1%);

[0058] Among them, gas phase SiO 2 The mass ratio with the surface treatment agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com