1,2-bis(diphenylphosphino) benzene

A technology for biphenyl phosphorus substitution and toluene, which is applied in the field of 1,2-bis(biphenyl phosphorus substitution) benzene, can solve the problems of low yield, high cost, and increase the cost of downstream products in the preparation process, and achieves the process Simple and easy to operate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

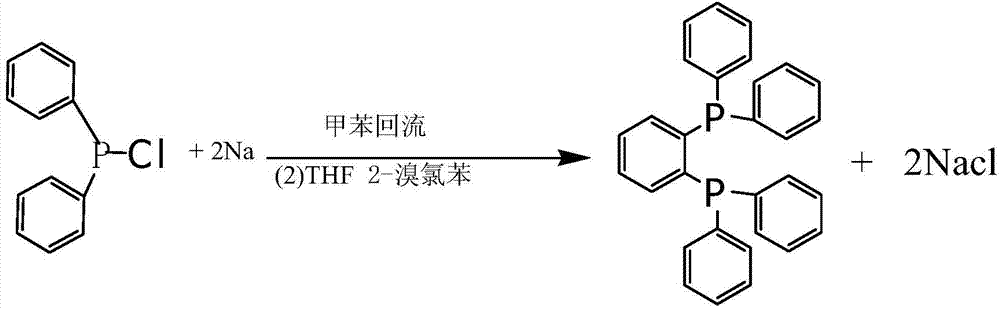

[0026] Please refer to figure 1 , figure 1 It is a schematic diagram of the reaction principle of the preparation method provided by the present invention. In fact, diphenylphosphine chloride is used as one of the raw materials, and 1,2-bis(biphenylphosphine) is obtained by reacting with metal sodium, 2-bromochlorobenzene, etc. benzene. Concrete preparation process is as follows:

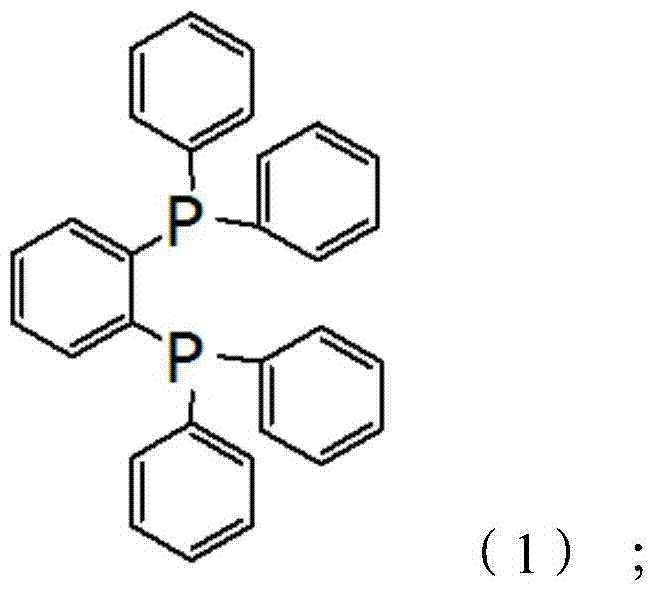

[0027] The structure of 1,2-bis(biphenylphosphoryl)benzene is shown in formula (1):

[0028]

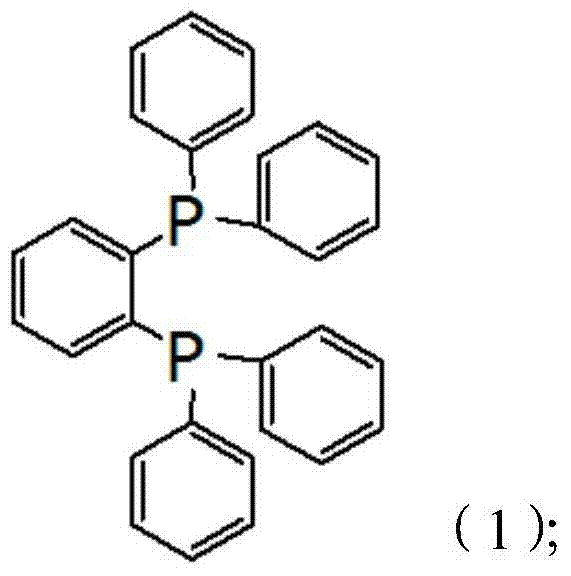

[0029] The structural formula of diphenylphosphine chloride is as shown in formula (2):

[0030]

[0031] Add 2 liters of toluene to a 20 liter anhydrous four-neck flask, then add 500 grams of sodium metal under nitrogen protection, heat to reflux for 2 hours and stir. When the metallic sodium melts into sodium beads, gradually add a mixture of 2200 g of diphenylphosphine chloride and 1 liter of toluene dropwise. Control the temperature at 120 degrees, after the addition, control the temperature...

Embodiment 2

[0033] Add 1.8 liters of toluene to a 20-liter anhydrous four-neck flask, then add 450 grams of sodium metal under nitrogen protection, heat to reflux for 2 hours and stir. When the metallic sodium melts into sodium beads, gradually add a mixture of 2100 g of diphenylphosphine chloride and 1 liter of toluene dropwise. Control the temperature at 100°C. After the addition, control the temperature at 100°C. React for 11 hours until the reaction system turns yellow to produce sodium diphenylphosphine. Cool slowly to room temperature and add 7.8 liters of tetrahydrofuran (THF) in batches to dissolve sodium diphenylphosphine, and stir at room temperature for 1.5 hours. Then cool down to 18 degrees and gradually add 850 grams of 2-bromochlorobenzene dropwise. The temperature was controlled below 18 degrees and the reaction was stirred at room temperature for 11 hours. Concentrate the mixture under reduced pressure, then add 2.8 liters of methanol at 30°C and stir to crystallize to ...

Embodiment 3

[0035] Add 2.2 liters of toluene to a 20-liter anhydrous four-neck flask, then add 550 grams of sodium metal under nitrogen protection, heat to reflux for 2 hours and stir. When the metallic sodium melts into sodium beads, gradually add a mixture of 2300 g of diphenylphosphine chloride and 1 liter of toluene dropwise. Control the temperature at 130°C. After the addition, control the temperature at 130°C. React for 12 hours until the reaction system turns yellow to produce sodium diphenylphosphine. Cool slowly to room temperature and add 8.2 liters of tetrahydrofuran (THF) in batches to dissolve sodium diphenylphosphine, and stir at room temperature for 1 hour. Then cool down to 20 degrees and gradually add 950 grams of 2-bromochlorobenzene dropwise. The temperature was controlled below 20 degrees and the reaction was stirred at room temperature for 12 hours. Concentrate the mixture under reduced pressure, then add 3.2 liters of methanol at 30°C and stir to crystallize to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com