Method for purifying amylose and amylopectin of wheat

A technology of amylose and amylopectin, applied in the field of biochemistry, to achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The purification of embodiment 1 common wheat amylose and amylopectin

[0034] 1. Extraction of wheat grain starch

[0035] Extraction of starch from wheat grain flour according to the modified Martin method. A certain amount of wheat grain is ground into flour with a filter screen and the bran is removed. Weigh 100g of flour, put the flour and water into the dough mixer (600W) according to the weight ratio of 2:1 and stir for 30min. After mixing, transfer the dough to a clean container and let it stand at room temperature for 30 minutes. Wrap the rested dough with 6 layers of gauze, put the gauze and dough in a large beaker, add 600mL of water three times to knead and wash the dough, and the washed emulsion is the crude starch extract. Transfer the starch solution into a centrifuge tube, centrifuge at 3500×g for 5 min, and pour off the supernatant. Scrape off the yellow gelatinous layer at the top of the precipitate as much as possible, and the white precipitate at...

Embodiment 2

[0040] The detection of embodiment 2 wheat amylose and amylopectin purity

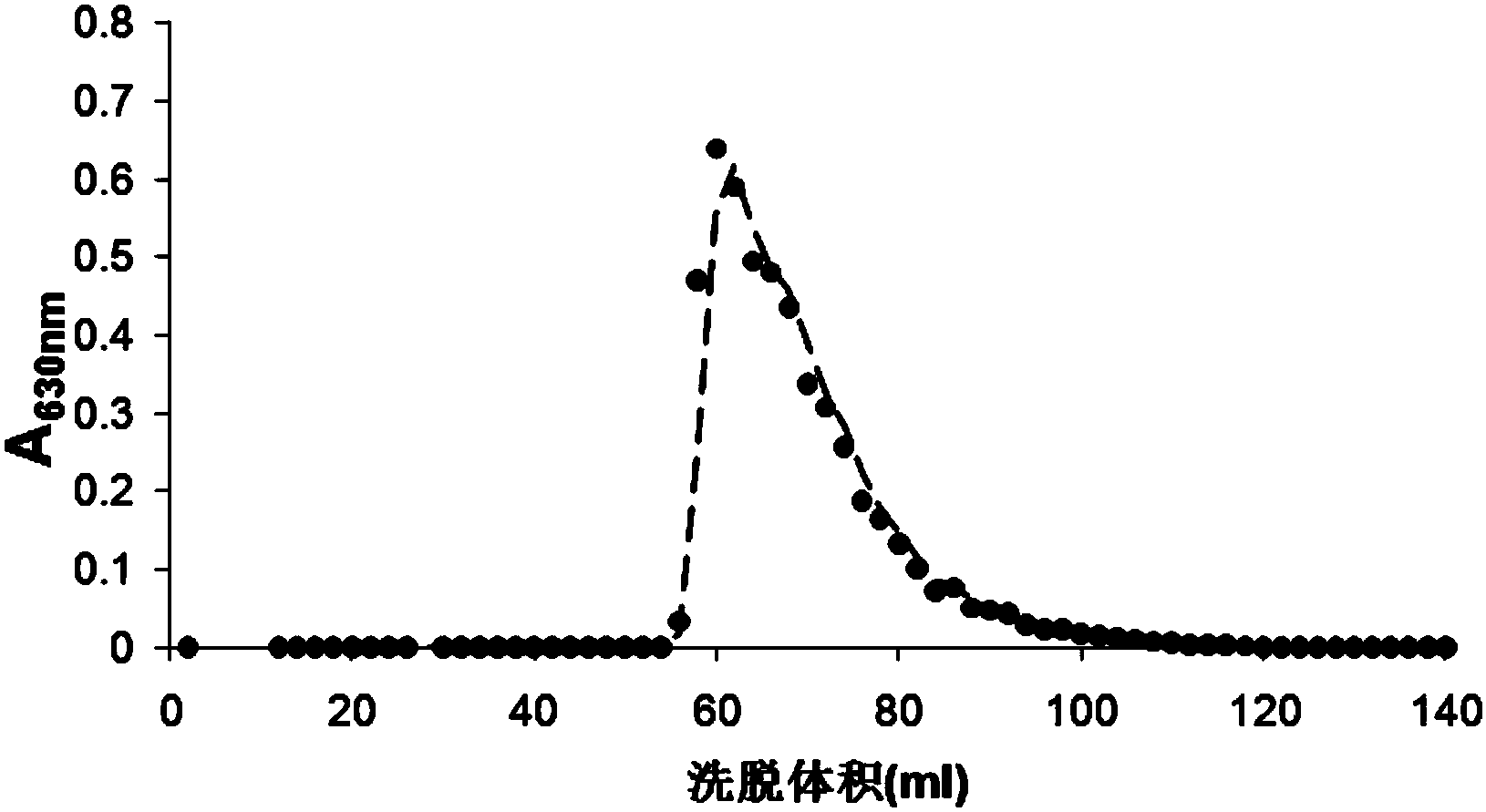

[0041] In order to ensure that the amylose and amylopectin extracted by the present invention can be used for accurate determination of the content and composition of wheat starch by colorimetry, it is necessary to detect the purity of both. The purity of amylose and amylopectin extracted in Example 1 was detected by iodine-binding color reaction and gel chromatography.

[0042] Disperse 100 mg of amylose and amylopectin extracted in Example 1 with 1 mL of absolute ethanol, add 9 mL of NaOH solution (1 mol / L) and heat in a boiling water bath for 15 min, shaking from time to time until the solution becomes clear. Add 60 mL of double-distilled water to the boiled solution, adjust the pH to 3.6 with 0.5 M HCl, and then adjust the volume to 100 mL. This solution is used as the working solution for subsequent analysis. Take 1.5mL of the above-mentioned amylose or amylopectin working solution, and add 20μl ...

Embodiment 3

[0043] Example 3 Comparison of Wheat Source and Potato Source Amylose and Amylopectin Absorption Spectra

[0044] In order to ensure that the amylose and amylopectin extracted by the present invention can be widely used in the determination of the starch content and composition of wheat grains by colorimetry, PI520554, PI614034, Liangmai No. 4, Mianmai 37, and Shumai were extracted according to Example 1. Amylose and amylopectin of wheat varieties such as 375, Shumai 482, and Zhengmai 9023. Disperse 100mg of each wheat-derived amylose and amylopectin with 1mL of absolute ethanol, add 9ml of NaOH solution (1mol / L) and heat in a boiling water bath for 15min, shake it from time to time until the solution becomes clear, then dilute to 100mL as a storage solution. Take 4 mL of amylose storage solution and 2.5 mL of amylopectin storage solution from each wheat source respectively, add 30 mL of double distilled water, adjust the pH to 3.6 with 0.5 M HCl, add 500 mL of iodine reagent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com