Genetically-engineered bacterium realizing high production of hyaluronic acid and application thereof

A technology of genetically engineered bacteria and hyaluronic acid, which is applied in the field of genetically engineered bacteria with high hyaluronic acid production, can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

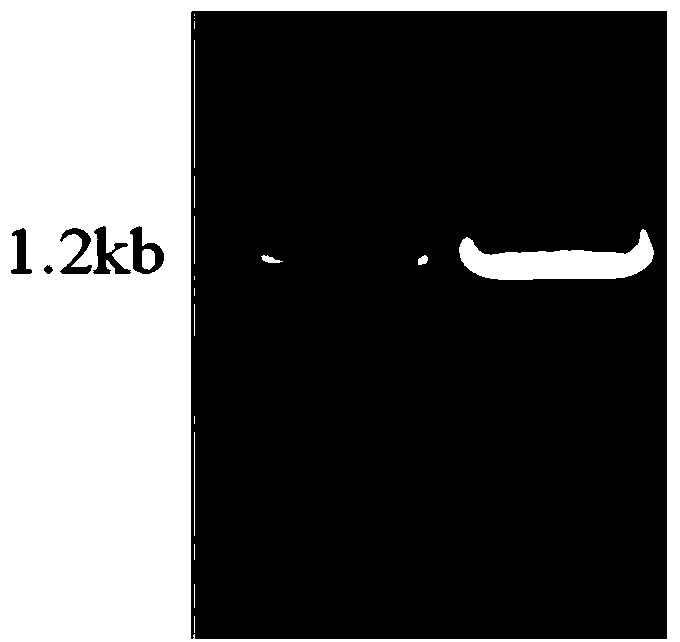

[0045] Construction of Corynebacterium glutamicum-Escherichia coli shuttle plasmid carrying hyaluronan synthase sHasA gene and CgHasB and CgHasC genes

[0046] Construction of plasmid pXMJ19-A: Based on the codon preference of Corynebacterium glutamicum and Escherichia coli, the gene sequence shasA of hyaluronan synthase sHasA was designed and chemically synthesized, as shown in SEQ ID No:1. The codon usage frequency of this gene and the protococcal Streptococcus equi hyaluronan synthase gene in Corynebacterium glutamicum is analyzed, and it is found that SEQ ID No:1 does not contain the highly rare codon (frequency of use) of Corynebacterium glutamicum 0-10%), and the number of common rare codons is only 29, which is also greatly reduced compared to 63 in the original gene. The codon usage frequency of SEQ ID No:1 in Escherichia coli was also analyzed, and it was found that SEQ ID No:1 is also suitable for expression in Escherichia coli, and does not contain highly rare codon...

Embodiment 2

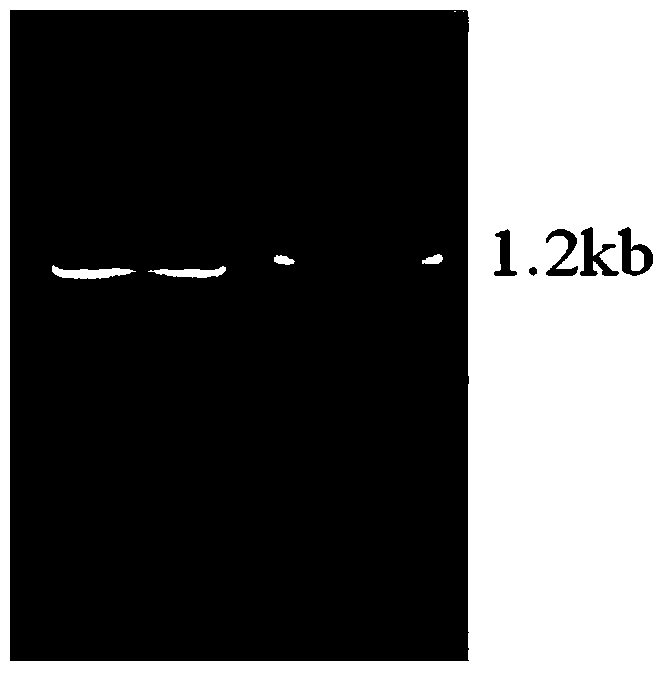

[0059] Construction of genetically engineered bacteria expressing hyaluronan synthase gene shasA and overexpressing CgHasB and CgHasB

[0060] The recombinant plasmid pXMJ19-A carrying hyaluronan synthase sHasA, the recombinant plasmid pXMJ19-AB overexpressing sHasA and CgHasB, and the recombinant plasmid pXMJ19-ABC overexpressing sHasA, CgHasB and CgHasC constructed in Example 1 were used as The competent cells of Corynebacterium glutamicum ATCC13032 are transformed by electroporation, and genetically engineered bacteria C.glu A, C.glu AB and C.glu ABC producing hyaluronic acid can be obtained. Add 5 μL of recombinant plasmid and 100 μL of Corynebacterium glutamicum ATCC13032 competent cells to a 1.5mL centrifuge tube, mix well, add a 0.1cm electroporation cup, and ice-bath for 30min; adjust the voltage of the electroporator to 1.8kV, and put the electroporation cup into Press the electric shock button on the electroporator; after the electric shock, add 1mL of SOC recovery m...

Embodiment 3

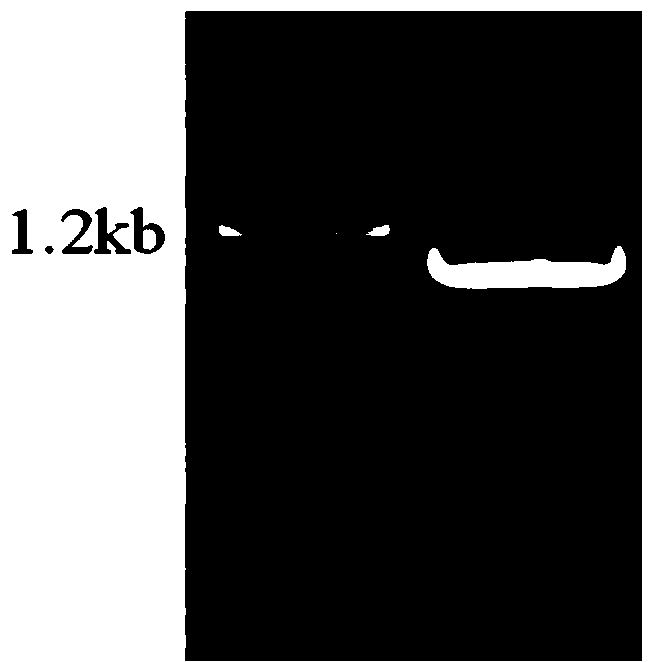

[0062] Production of Hyaluronic Acid Using Genetically Engineered Bacteria C.glu A, C.glu AB and C.glu ABC

[0063] The genetically engineered bacteria C.glu A, C.glu AB and C.glu ABC that will be transferred into the Corynebacterium glutamicum C.glu P of original plasmid pXMJ19 and embodiment 2 are inoculated in LB liquid culture medium (containing 5 μ g / mL Chloramphenicol), cultured at 37°C and 200rpm for 16 hours, inserted into LB liquid medium with a glucose concentration of 40g / L at a ratio of 5%, cultivated at 37°C and 200rpm for 3h, added IPTG (final concentration 1mM) , continue culturing for 24 hours, and centrifuge at 8000 rpm at room temperature to obtain a hyaluronic acid-containing fermentation broth. Take 1 mL of the obtained fermentation broth and add 1 mL of 0.1% w / v SDS solution to mix, incubate at room temperature for 20 minutes; centrifuge at 12,000 rpm for 10 minutes, transfer the supernatant to a new 10 mL EP tube, add 2 times the volume of ice ethanol, 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com