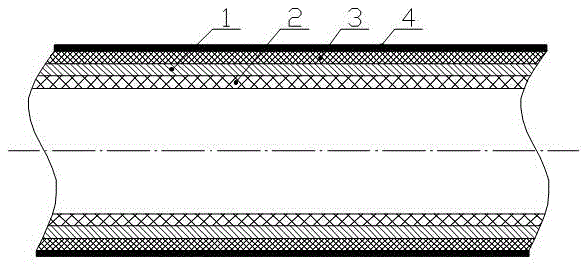

Steel wood plastic composite pipe

A technology for composite pipes and wood-plastic composite materials, applied in the field of steel-wood-plastic composite pipes, can solve the problems of pipeline corrosion, limited service life of anti-rust paint, corrosion and peeling of anti-rust paint, etc., to improve flame retardant performance and improve fire performance. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The fireproof coating layer of the steel-wood-plastic composite pipe of the present invention is made of the following raw materials in parts by weight: 26 parts of resin matrix, 22 parts of solvent, 46 parts of P-C-N flame retardant system, 6 parts of flame retardant synergist, 5 parts of filler, auxiliary Appropriate dose.

Embodiment 2

[0019] The fireproof coating layer of the steel-wood-plastic composite pipe of the present invention is made of the following raw materials in parts by weight: 30 parts of resin matrix, 28 parts of solvent, 52 parts of P-C-N flame retardant system, 10 parts of flame retardant synergist, 10 parts of filler, auxiliary Appropriate dose.

Embodiment 3

[0021] The fireproof coating layer of the steel-wood-plastic composite pipe of the present invention is made of the following raw materials in parts by weight: 28 parts of resin matrix, 25 parts of solvent, 49 parts of P-C-N flame retardant system, 8 parts of flame retardant synergist, 8 parts of filler, auxiliary Appropriate dose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com