Contact lenses with colloid photonic crystal structural color and preparation method of contact lenses

A colloidal photonic crystal, contact lens technology, applied in glasses/goggles, optics, optical components, etc., can solve the problems of pigment or pigment wearer discomfort, single color, eye diseases, etc., to improve the eye hypoxia , Bright colors, the effect of promoting oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

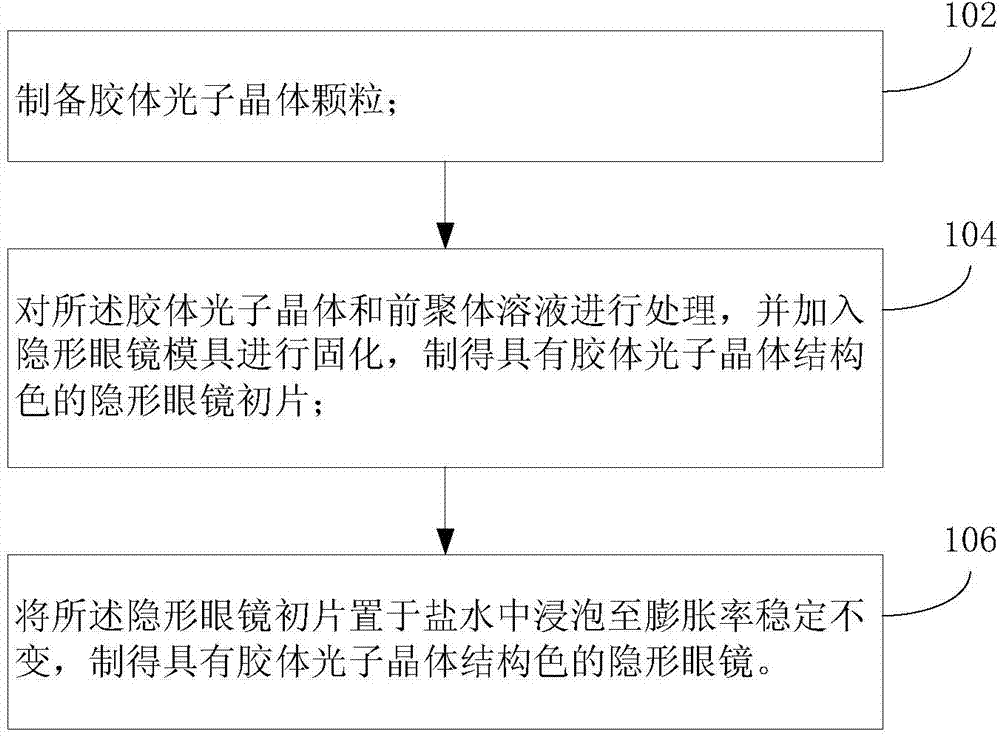

[0032] The preparation method of the contact lens with colloidal photonic crystal structural color of the present application comprises the following steps:

[0033] Step 102: Prepare colloidal photonic crystal particles.

[0034] Colloidal photonic crystals are prepared by self-assembly of monodisperse microspheres through gravity sedimentation, electrostatic force or capillary force. The shape of the prepared colloidal photonic crystal includes spherical, hemispherical, ellipsoidal, columnar or thin slice.

[0035] Monodisperse microspheres include polystyrene, polymethyl methacrylate, silicon dioxide, titanium dioxide, iron oxide, ferric oxide, gold and silver, or any combination of more. Specifically, it can be microspheres of polystyrene, polymethyl methacrylate, silicon dioxide, titanium dioxide, iron oxide, ferric oxide, gold, silver, or polystyrene, polymethyl methacrylate, di Modified microspheres of silicon oxide, titanium dioxide, iron oxide, iron oxide, gold,...

Embodiment 1

[0046] 1. Preparation of colloidal photonic crystal particles:

[0047] 10 mL of monodisperse polystyrene microspheres with a diameter of 180 nm were formulated into an emulsion with a mass concentration of 4.0 wt%, and then dispersed into 100 mL of hexadecanon containing surfactant Hypermer 2296 (2.0 wt%) Colloidal photonic crystal particles can be obtained by self-assembling in an oven at 50°C for 72 hours in alkanes. Then, the colloidal photonic crystal particles are fully washed with n-hexane to remove the n-hexadecane, and then dried to obtain the colloidal photonic crystal particles. The colloidal photonic crystal particles were dispersed into a mixed solution of hydroxyethyl methacrylate and methylene bisacrylamide (molar ratio 30:1), and Irgacure 2959 (mass volume ratio 0.5%) was used as the initiator.

[0048] 2. Curing treatment of prepolymer solution:

[0049] Add 100 microliters of the above-mentioned prepolymer solution mixed with colloidal photonic crystal part...

Embodiment 2

[0053] 1. Preparation of colloidal photonic crystal particles:

[0054] Monodisperse silica microspheres with diameters of 180 nanometers, 220 nanometers and 320 nanometers were self-assembled by pulling method to prepare colloidal photonic crystal films, and many small colloidal photonic crystal fragments could be obtained by tapping the film. Then, the colloidal photonic crystal fragments assembled by microspheres of different sizes were mixed and dispersed into the mixed solution of hydroxyethyl methacrylate and methylene bisacrylamide (molar ratio 30:1), and Irgacure 2959 (mass volume ratio 0.5% ) as the initiator.

[0055] 2. Curing treatment of prepolymer solution:

[0056] Add 100 microliters of the above-mentioned prepolymer solution mixed with colloidal photonic crystal particles into a mold for contact lens preparation, irradiate with an ultraviolet lamp at 0°C for 30 minutes, and cure to obtain a contact lens primary lens.

[0057] 3. Hydration treatment of contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com