Static suppressor with overcurrent protection functions, and manufacturing method thereof

A technology of electrostatic suppression and overcurrent protection, applied in the direction of overvoltage protection resistors, current response resistors, resistors, etc., can solve the problem of reducing the space requirement of the circuit board and the number of devices, the difficulty of batch continuous production, and the inability to meet the surface Soldering and other problems, to achieve the effect of excellent overcurrent and overvoltage protection, low production cost and small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

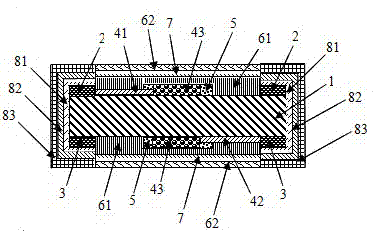

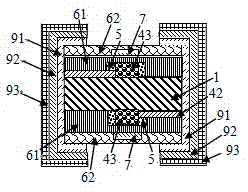

[0057] An electrostatic suppressor with an overcurrent protection function, comprising: a ceramic substrate 1, a front electrode 2 and a back electrode 3 respectively formed on the upper and lower surfaces of the ceramic substrate 1, and respectively formed on the upper surfaces of the upper and lower surfaces of the ceramic substrate 1 The electrode 41 and the lower surface electrode 42, the insulating layer 5 covering the middle position of the surface electrode, the upper surface electrode gap 411 and the lower surface electrode gap 421, the upper insulating layer gap (51) and the lower insulating layer gap (52), fill the The pressure-sensitive material layer 43 in the above-mentioned gap covers the surface electrodes 41 and 42, the insulating layer 5 and the first protective layer 61 of the pressure-sensitive material layer 43, so that at least one of the front electrode 2 or the back electrode 3 at both ends of the ceramic substrate 1 Form the melt layer 7 electrically con...

Embodiment 2

[0065] In the manufacturing steps of the electrostatic suppressor with overcurrent protection function described in Embodiment 1: in the tenth step, the melt layer 7 uses a bonding process to spot weld at least one metal alloy wire to both sides of the front electrode 2 and the back electrode 3. end;

[0066] Other steps are with embodiment 1.

Embodiment 3

[0068] In the manufacturing steps of the electrostatic suppressor with overcurrent protection function described in Embodiment 1: in the tenth step, the melt layer 7 is spot-welded to both ends of the front electrode 2 by using a bonding process at least one metal alloy wire;

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com