12kV-5000A/63kA armored fixation type double-bus cabinet

A 12kv-5000a, 1.12kv-5000a technology, applied in busbar/line layout, substation/distribution device enclosure, substation/switchgear cooling/ventilation, etc. Problems such as not in place, points and not in place, etc., to ensure the rated peak withstand current, facilitate handling and installation, and reduce the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

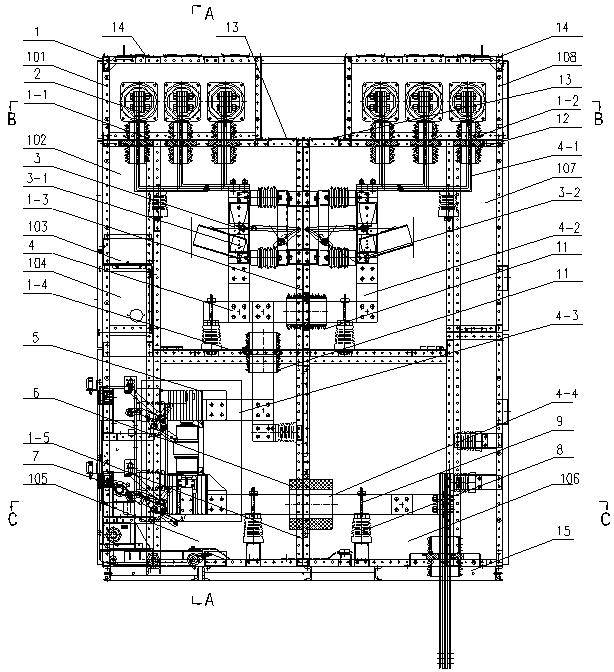

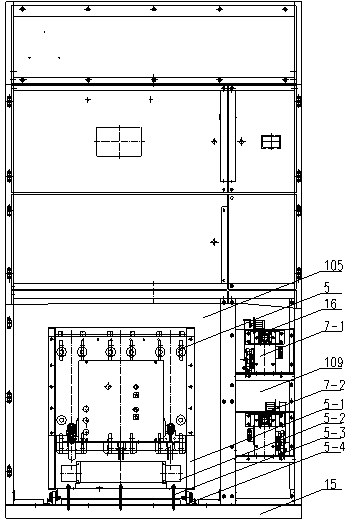

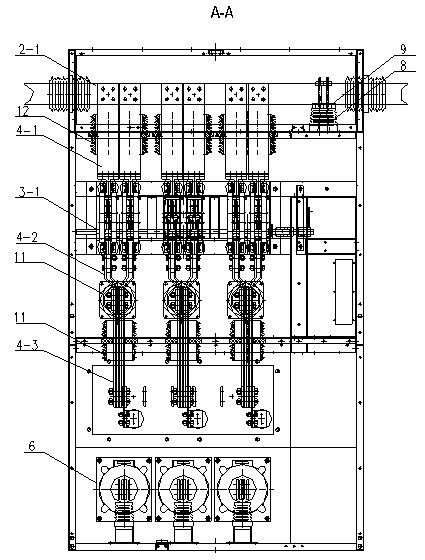

[0056] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

[0057] Such as Figure 1 to Figure 5 As shown, the present invention includes an armored cabinet body 1, and the armored cabinet body 1 divides the interior of the cabinet body into nine compartments through internal partitions, which are respectively the working main busbar room 101 located at the front top of the armored cabinet body 1, the The spare main bus room 108 at the top of the back of the armored cabinet 1, the working isolation room 102 located in the middle of the front of the armored cabinet 1, the spare isolation room 107 located in the middle of the back of the armored cabinet 1, and the lower part of the front of the armored cabinet 1 The circuit breaker room 105, the incoming line room 106 located at the lower part of the back of the armored cabinet body 1, the mechanism room 109 located on the right side of the circuit breaker room 105, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com