Multi-phase high-speed AC motor system

An AC motor, high-speed technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of large harmonic components of the stator current, achieve strong fault tolerance, improve efficiency, and eliminate pulsating torque effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

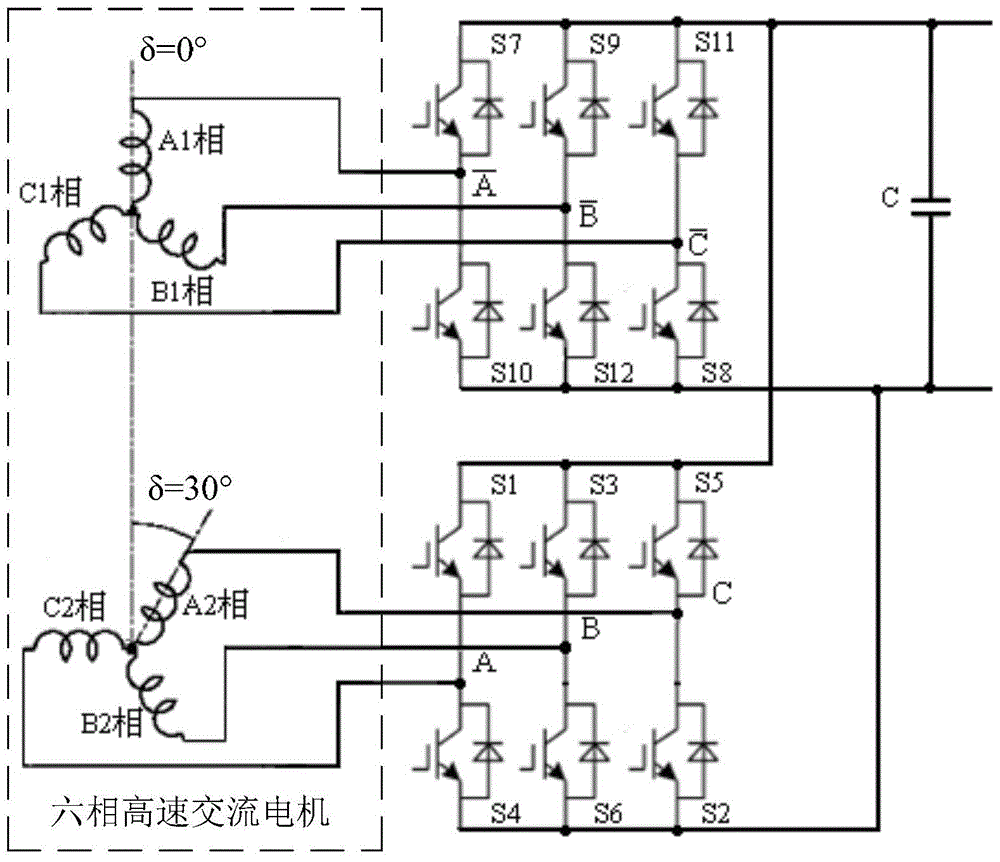

[0025] Embodiment 1: The multi-phase high-speed AC motor system described in this embodiment includes: an m-phase high-speed AC motor and m / 3 three-phase power converters, wherein m is the phase number of the motor, m=3k, k is a positive integer greater than 1;

[0026] The m-phase high-speed AC motor includes a stator and a rotor;

[0027] The stator includes: m / 3 sets of three-phase annular windings and annular iron cores, the phase difference between the corresponding phases of adjacent two-phase annular windings in each set of three-phase annular windings is δ electrical angle, and δ satisfies δ=±180° / m; each set of three-phase toroidal windings is star-connected, and the three output terminals of each three-phase winding are respectively connected to the three AC input terminals of a three-phase power converter in one-to-one correspondence;

[0028] m / 3 three-phase power converters share a DC bus, and the output currents of the corresponding phases of two adjacent three...

specific Embodiment approach 2

[0031] Embodiment 2: The multi-phase high-speed AC motor system described in this embodiment includes: an m-phase high-speed AC motor and an m-phase power converter, wherein m is the phase number of the motor, and m is a natural number greater than or equal to 5 ;

[0032] The m-phase high-speed AC motor includes a stator and a rotor;

[0033] The stator includes: m-phase annular windings and annular iron cores, the phase difference between adjacent two-phase annular windings is δ electrical angle, and δ satisfies δ=±360° / m; the output ends of each phase of the m-phase annular windings are respectively It is connected to an AC input terminal of the m-phase power converter in one-to-one correspondence; the output current difference between adjacent phases of the m-phase power converter is δ electrical angle;

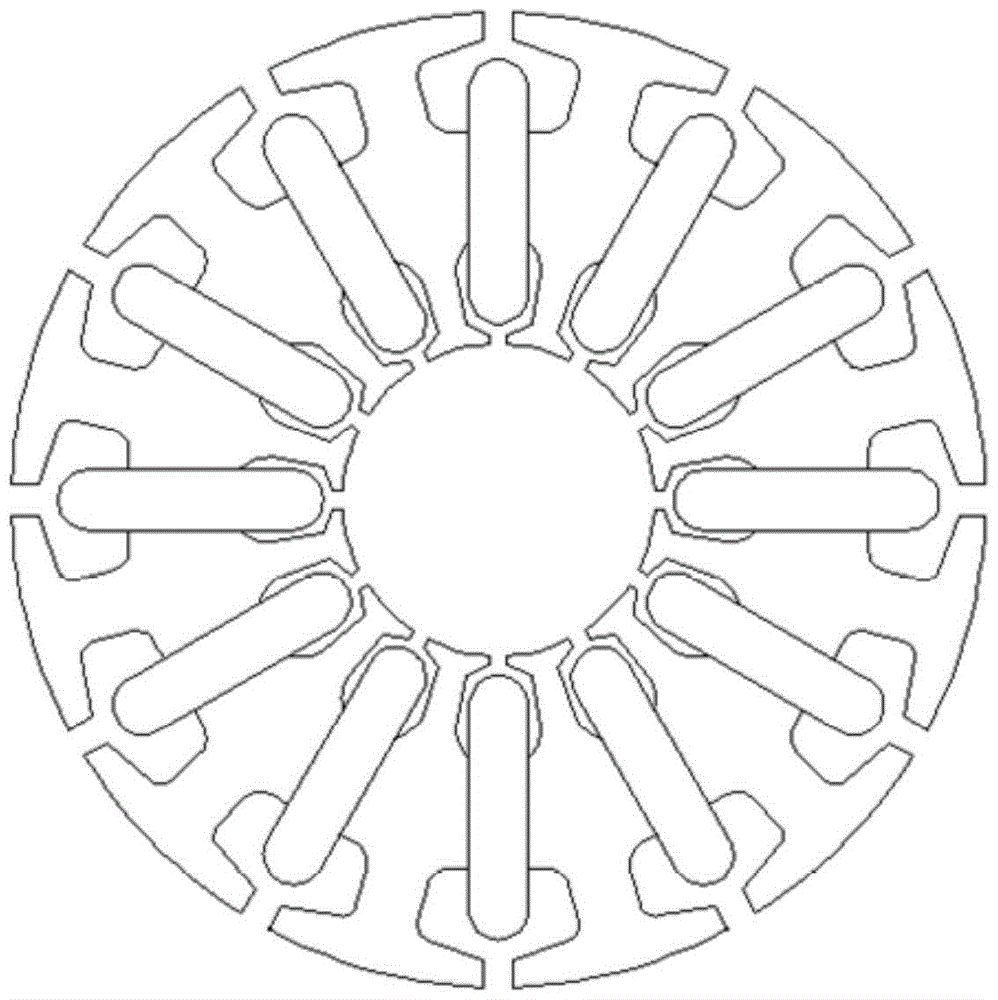

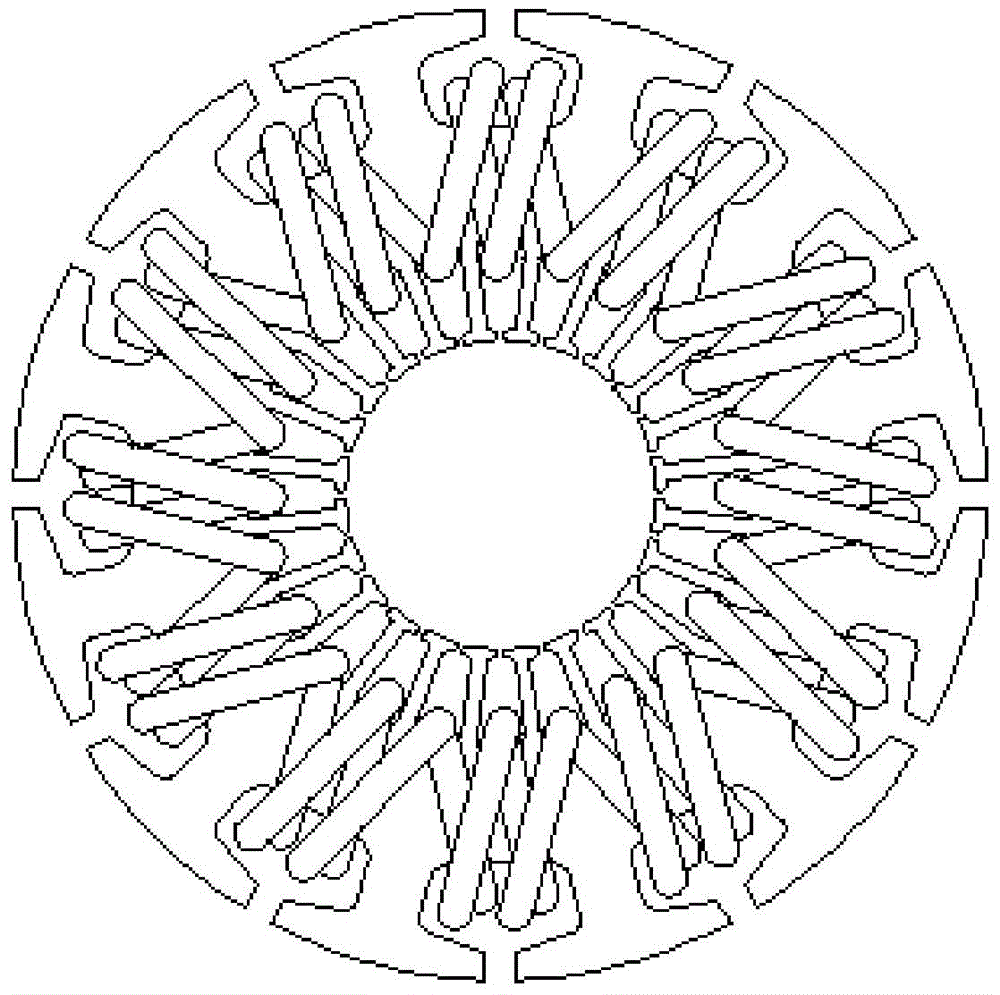

[0034] The inner side wall of the annular iron core is provided with Z slots, and the outer side wall is provided with y slots. The slots on the inner side wall and the ...

specific Embodiment approach 3

[0035] Specific embodiment three: This embodiment is to further illustrate the multi-phase high-speed AC motor system described in specific embodiment one or two. In this embodiment, when the number of slots on the inner side wall of the annular core is Z=2mp, where p is The number of pole pairs of the m-phase high-speed AC motor;

[0036] Z=y, and the grooves on the inner wall and the grooves on the outer wall correspond one by one;

[0037] The m-phase annular winding is embedded in the slot on the inner side wall of the annular core, and the m-phase annular winding is a single-layer structure. Only one effective side of a rectangular coil is embedded in each inner side wall slot, and the opposite side of the effective side of the rectangular coil is embedded. in the outer wall groove corresponding to the inner wall groove.

[0038] In practical applications, according to the multi-phase high-speed AC motor system structure described in this embodiment, when m=6, as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com