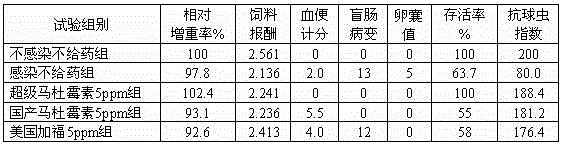

Application of super maduramycin in the preparation of drugs for preventing and treating poultry coccidiosis

A technology for livestock and poultry coccidiosis and maduramycin, applied in the field of livestock and poultry medicines, can solve problems such as increased technical difficulty, restrictions on the use and application range of maduramycin, chicken poisoning, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

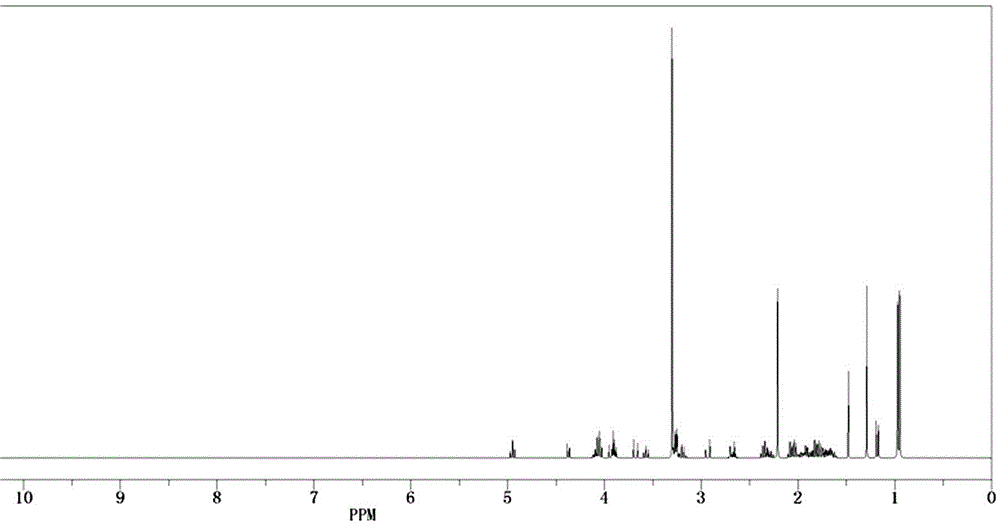

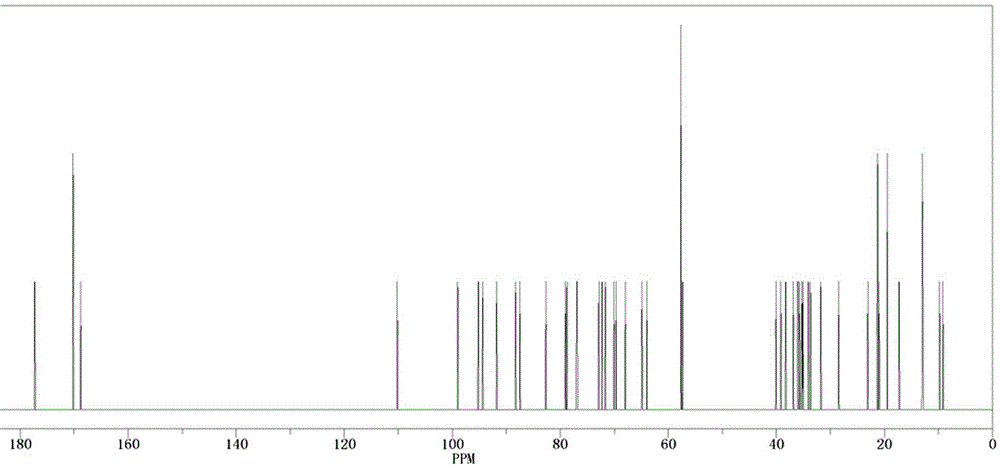

[0025] Super Maduramycin, its structural formula is as follows:

[0026] .

[0027] The synthetic method of above-mentioned super maduramycin, it comprises the following steps:

[0028] Accurately weigh 50g of maduramycin and 80ml of glacial acetic acid into a 1000ml three-neck flask, mix and stir for 2min at room temperature, and slowly add 116ml of acetic anhydride at a temperature of 5°C within 5min. Another 0.5ml of MSA was diluted with 8ml of glacial acetic acid and added to the three-necked flask within 10min. The temperature was raised to 60°C and the reaction was stirred for 50 minutes. After the reaction is over, pour the product into deionized water while stirring (the volume ratio of product to deionized water is 1:10), filter, wash the filter cake with deionized water to remove residual impurities and MSA, and then vacuum at 60°C After drying to constant weight, 51.3 g of white super maduramycin crystals were obtained.

Embodiment 2

[0030] Super Maduramycin, its structural formula is as follows:

[0031] .

[0032] The synthetic method of above-mentioned super maduramycin, it comprises the following steps:

[0033] Accurately weigh 50g of maduramycin and 80ml of glacial acetic acid into a 1000ml three-neck flask, mix and stir for 2min at room temperature, and slowly add 116ml of acetic anhydride at a temperature of 5°C within 5min. Another 0.5ml of MSA was diluted with 8ml of glacial acetic acid and added to the three-necked flask within 10min. The temperature was raised to 65°C and the reaction was stirred for 60 minutes. After the reaction, the product was poured into deionized water while stirring (the volume ratio of product to deionized water was 1:10), filtered, the filter cake was washed with deionized water, and then vacuum-dried at 60°C to constant weight to obtain 53.6g white super maduramycin crystals.

Embodiment 3

[0035] Super Maduramycin, its structural formula is as follows:

[0036] .

[0037] The synthetic method of above-mentioned super maduramycin, it comprises the following steps:

[0038] Accurately weigh 50g of maduramycin and 80ml of glacial acetic acid into a 1000ml three-neck flask, mix and stir for 2min at room temperature, and slowly add 116ml of acetic anhydride at a temperature of 5°C within 5min. Another 1ml of MSA was diluted with 8ml of glacial acetic acid and added to the three-necked flask within 10min. The temperature was raised to 65°C and the reaction was stirred for 60 minutes. After the reaction, the product was poured into deionized water while stirring (the volume ratio of product to deionized water was 1:10), filtered, the filter cake was washed with deionized water, and then vacuum-dried at 60°C to constant weight to obtain 52.4g white super maduramycin crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com