Sand Casting Method for Medium Pressure 22nd Stator Blade of H-Class Combined Cycle Steam Turbine

A combined cycle and sand casting technology, which is applied to casting molding equipment, molds, cores, etc., can solve problems such as difficult to meet, and achieve the effects of reducing procurement costs, reducing pollution, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

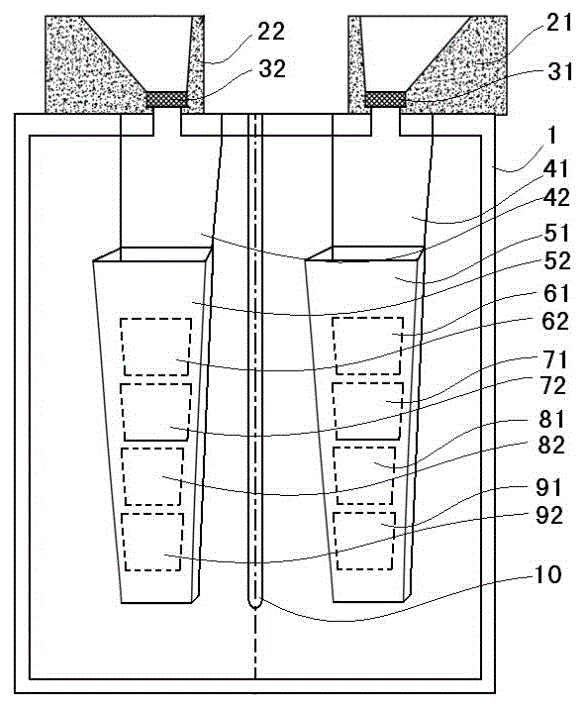

[0064] The specific implementation of the sand casting method for the medium-pressure 22nd-stage stator blade of the H-stage combined cycle steam turbine of the present invention is given below in conjunction with the accompanying drawings.

[0065] see figure 1 . A sand casting method for the 22nd stage stator vane of medium pressure stage H combined cycle steam turbine, comprising the following steps:

[0066] (1) Process design

[0067] ①Mould design: In order to improve production efficiency, two static blades are set in the same sand box 1: the first static blade 51 and the second static blade 52 models.

[0068] ② Pouring position and pouring and riser design: According to the structural characteristics of the blade due to the obvious thickness gradient from the large end to the small end, in order to make the machining allowance as small as possible, the vertical pouring and riser (including the first riser 41 , The second riser 42) The body pouring method; this can fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com