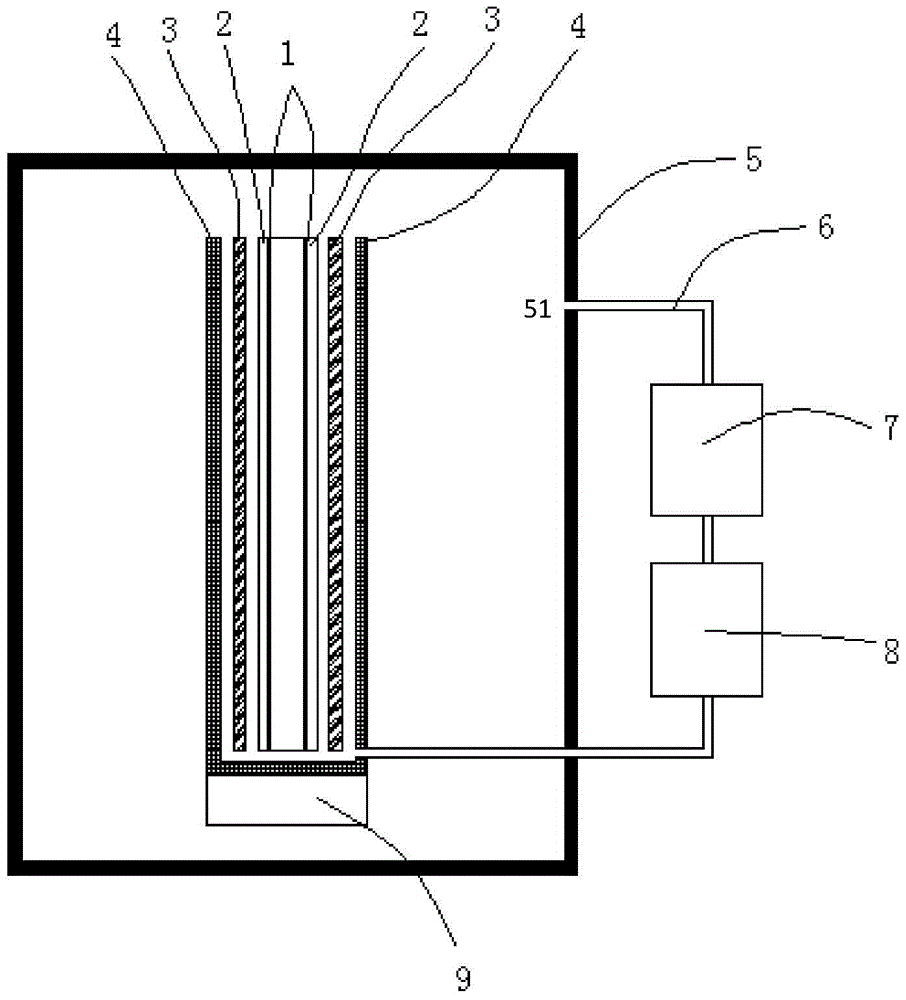

Casting mold for rod-shaped silicon material and casting method thereof

A technology for casting mold and silicon material, which is applied in the field of rod-shaped silicon material casting mold and its casting, and can solve the problems of expansion, deformation and damage of the casting mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043] In the following examples and comparative examples, the cast rod-shaped silicon material has a length of 1200 mm and a diameter of 60 mm. Vibration refers to the eccentric vibration of the motor, the vibration power is 250W, the frequency is 1000Hz, and the vibration time is 10min. Annealing refers to resistance wire heating, the heating temperature is 700° C., and the heating time is 2 hours. In Comparative Example 3, the heating time is 4 hours. Cooling refers to blowing argon gas at about 40°C into the casting mold, the cooling time is 2h, and other factors are the same.

[0044] Table 1: The difference between the process in the embodiment and the comparative example

[0045]

shock

annealing

cool down

Example

Have

Have

Have

Comparative example 1

no

no

no

Comparative example 2

no

Have

Have

Comparative example 3

no

Lengthen

Have

Comparative example 4

Have

no

Have

Comparative example 5

Have

Have

no

[0046] The process difference betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com