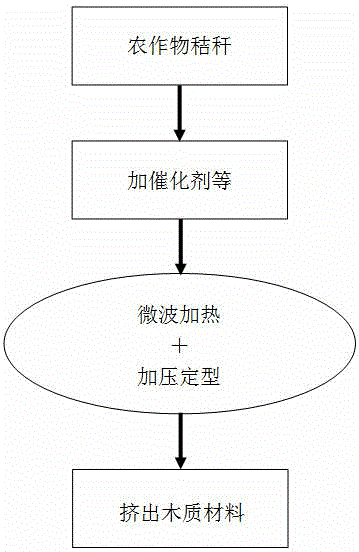

Method for making environment-friendly wood material through microwave shaping of straws

A technology of wood materials and straw, which is applied in the field of microwave shaped straw to manufacture environmentally friendly wood materials, can solve the problems of processing technology limitations, difficulty in meeting requirements, low production efficiency, etc., and achieve the effects of avoiding health damage, good sound insulation effect, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

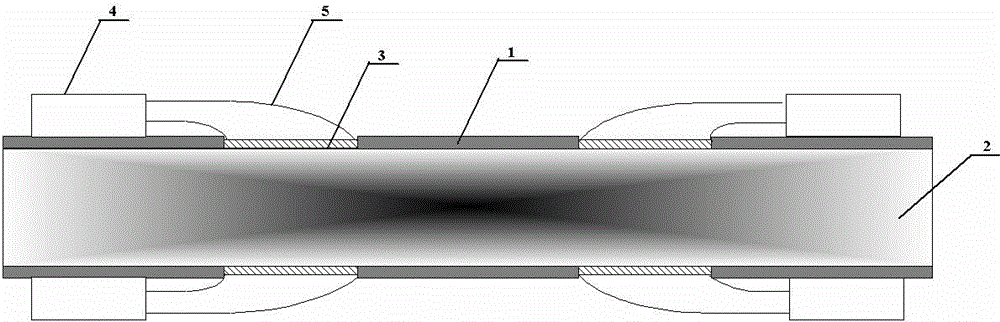

[0035] Specific embodiment: directly harvested wheat straw is mixed with 3% sulfuric acid catalyst, and squeezed into the microwave reaction cavity through a feeder. The reaction chamber is cylindrical and made of stainless steel. Several 1 kW magnetrons are arranged outside the chamber to generate microwaves with a frequency of 2450 MHz. The microwave is transmitted through the waveguide, and enters the reaction chamber from the glass window on the surface of the chamber, and deeply heats the raw material of wheat straw in the chamber, heating to 150 ℃ within 15 minutes, so that the straw dries and produces lignin, increasing the viscosity of the material. The microwave reaction chamber is also used as an extrusion die. Under the condition of continuous feeding from the feeder, the straw is pressed and shaped at 150 ℃ and extruded into a long cylindrical stick material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com