Water electrolysis cup

A water cup and electrolytic power supply technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as deterioration, difficulty in reaching the standard of water quality at the factory, outdated treatment process in water plants, etc., and achieve sterilization. Improved purification ability and low redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

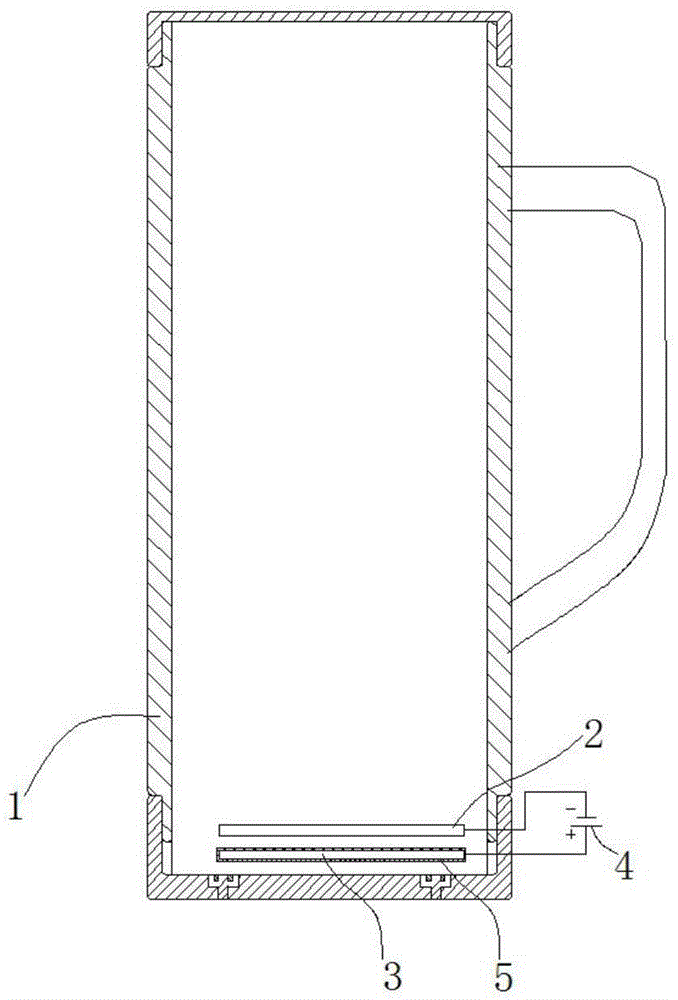

[0052] Refer to the electrolysis water cup of this embodiment figure 1 , Including a tank 1 with a water filling port and a water pouring port on the top and an electrolysis power supply 4. The inner bottom of the tank 1 is provided with a pair of cathode electrodes 2 and anode electrodes 3. The cathode electrodes 2 and anode electrodes 3 are respectively connected to the positive and negative electrodes of the electrolysis power supply 4 pole. In this embodiment, the electrolytic power supply 4 is a high-level, narrow-pulse-width regulated 30 volt DC pulse power supply, and an alternating pulse power supply can also be used (but the forward voltage is greater than the reverse voltage).

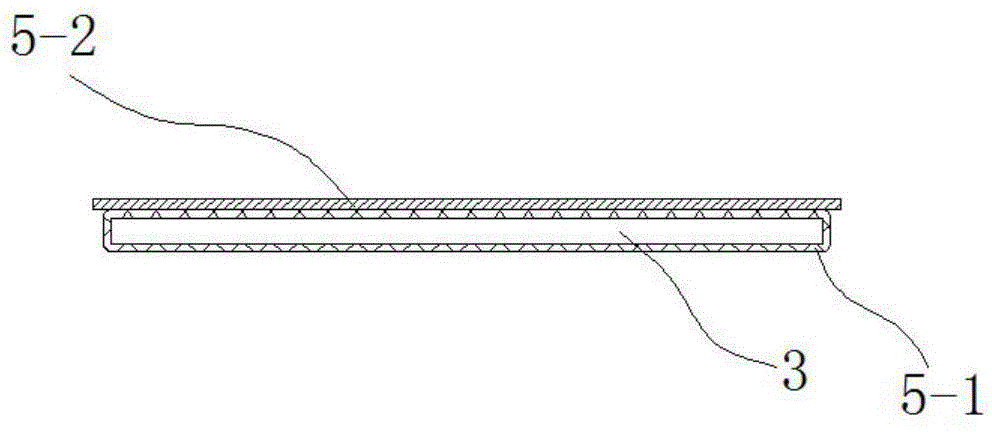

[0053] In this embodiment, a water-permeable membrane 5 is provided between the cathode electrode 2 and the anode electrode 3. The water-permeable membrane 5 is close to the anode electrode 2 and covers the entire surface of the anode electrode 3, that is, the water-permeable membrane 5 covers th...

Embodiment 2

[0073] The electrolyzed water cup of this embodiment is basically the same as that of the first embodiment. The difference from the first embodiment is that the distance δ between the water-permeable membrane 5 and the cathode electrode 2 in this embodiment is 0 mm, that is, the water-permeable membrane 5 is in close contact with the cathode at the same time. Electrode 2 and anode electrode 3. The water-permeable membrane 5 still uses a PVDF ultrafiltration membrane with an average hydrophobic pore size of 0.03 microns and a thickness of 0.1 mm.

[0074] Perform water electrolysis experiments on the electrolyzed water cups of this embodiment and embodiment 1. The source water is city-supplied tap water, ORP=+320mv, pH=7.1, TDS=148mg / L, other experimental conditions are the same as those of embodiment 1, two experiments The results are shown in Table 2:

[0075] Table 2

[0076]

[0077]

[0078] Analysis of results

[0079] 1) Within a certain range, as δ increases, the hydrogen con...

Embodiment 3

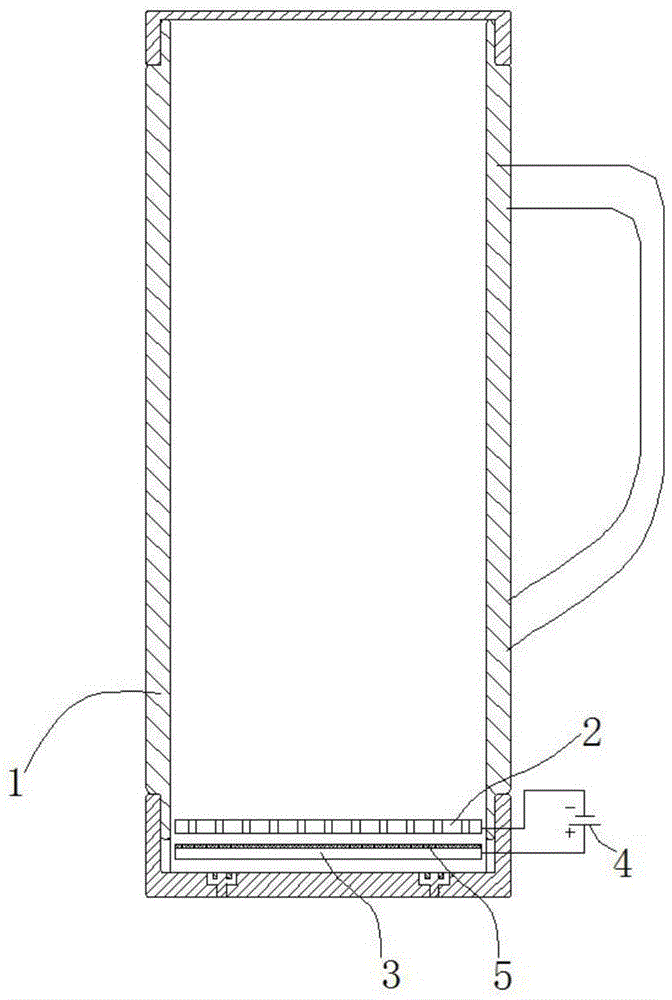

[0082] The electrolyzed water cup of this embodiment is basically the same as the first embodiment, such as figure 2 As shown, the different changes from the first embodiment are: 1) A first through hole 8 is opened on the cathode electrode 2 with a diameter of 1 mm; 2) A water-permeable membrane 5 covers part of the surface of the anode electrode 3 (anode electrode The entire surface facing the cathode electrode 2); 3) The distance δ between the water-permeable membrane 5 and the cathode electrode 2 is 2 mm.

[0083] The electrolysis water cup of this embodiment is subjected to a water electrolysis experiment. In this embodiment, 24 first through holes with a diameter of 1mm are uniformly distributed on the cathode electrode, and the electrolysis time is 20 minutes. Other experimental conditions and detection methods are the same as those of the first embodiment. The experimental results are as follows in Table 3:

[0084] table 3

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com