Non-sintered alkaline-residue ceramsite with high alkaline residue mixing amount and manufacturing method thereof

A technology of ceramsite and caustic soda, which is applied in the field of caustic soda slag-free ceramsite with high alkali slag content and its manufacturing field, which can solve the problems of land resource destruction and energy waste, and achieve the effects of reducing pollution, reducing energy consumption, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

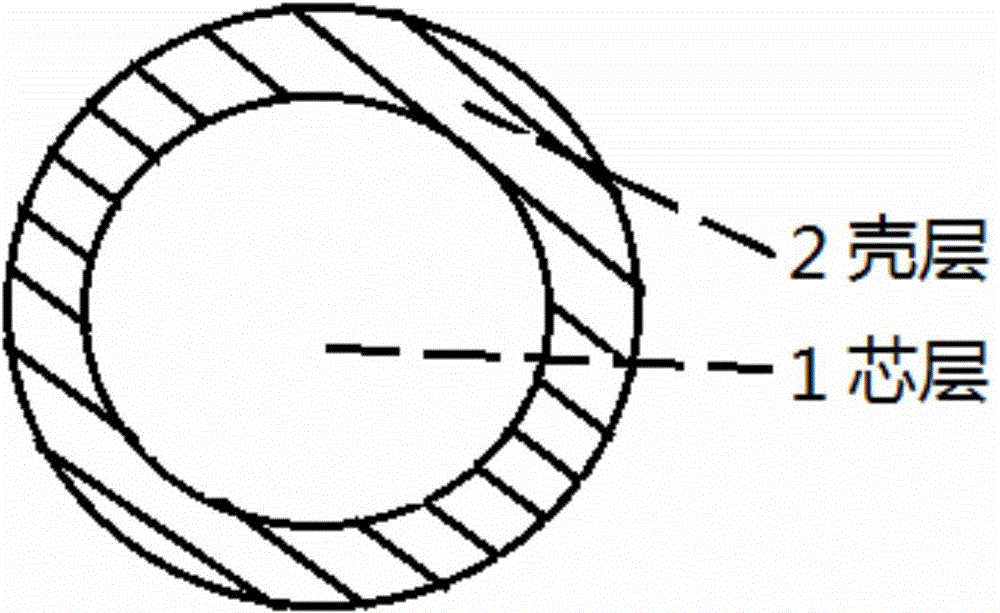

[0032] Alkali slag core layer: 40wt% alkali slag, 30% fly ash, 30wt% glass powder; cement shell: 35wt% cement, 35wt% glass powder, 30% fly ash; aqueous solution: NaOH2%, water 98%; The water-cement ratio of the core layer: 0.2; the water-cement ratio of the shell layer: 0.3.

[0033] The dry material ratio of the shell layer and the core layer is 0.5. Considering the size and irregular shape of the ceramsite and a small amount of adhesion between the ball-forming disc and the shell slurry during the wrapping process, the mass percentage of each ceramsite shell layer is about 20. -30wt%, the shell thickness is about 2-3mm. After curing for 5 days, the chloride ion capacity of ceramsite soaked in deionized water for 24 hours is about 0.7% (accounting for the total amount of chloride ions).

example 2

[0035] Alkali slag core layer: 45wt% alkali slag, 25% fly ash, 30wt% glass powder; cement shell: 40wt% cement, 30wt% glass powder, 30% fly ash; aqueous solution: NaOH2%, water 98%; The water-cement ratio of the core layer: 0.2; the water-cement ratio of the shell layer: 0.3.

[0036] The dry material ratio of the shell layer and the core layer is 0.5. Considering the size and irregular shape of the ceramsite and a small amount of adhesion between the ball-forming disc and the shell slurry during the wrapping process, the mass percentage of each ceramsite shell layer is about 20. -30wt%, the shell thickness is about 2-3mm. After 5 days of curing, the chloride ion capacity of ceramsite soaked in deionized water for 24 hours is about 1% (accounting for the total amount of chloride ions).

example 3

[0038] Alkali slag core layer: alkali slag dosage 50wt%, fly ash 25%, glass powder 20wt%, lime 5wt%; cement shell layer: cement 45wt%, glass powder 35wt%, fly ash 20%; aqueous solution: NaOH2%, Water 98%; core water-cement ratio: 0.2; shell water-cement ratio: 0.3.

[0039] The dry material ratio of the shell layer and the core layer is 0.5. Considering the size and irregular shape of the ceramsite and a small amount of adhesion between the ball forming disc and the shell slurry during the wrapping process, the mass percentage of each ceramsite shell layer is about 20. -30wt%, the shell thickness is about 2-3mm. After curing for 5 days, the chloride ion capacity of ceramsite soaked in deionized water for 24 hours is about 1.6% (accounting for the total amount of chloride ions).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com