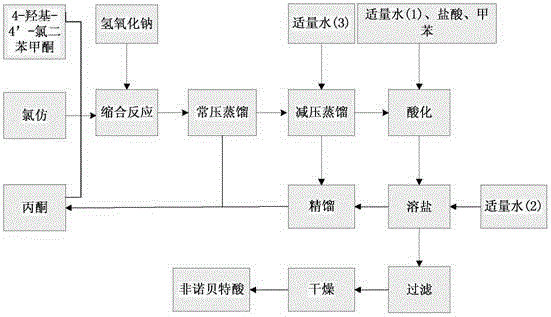

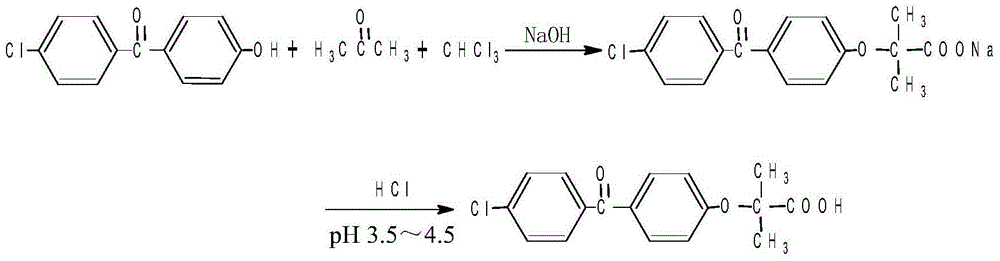

Method for preparing fenofibric acid by using inorganic alkali as catalyst

A technology of fenofibrate acid and inorganic base, applied in the field of catalyzed synthesis of fenofibrate acid, can solve the problems of high product cost, large consumption of raw materials, high cost, etc., and meet the requirements of large-scale industrial application, yield and quality assurance , The effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 120g of acetone and 50g of 4-hydroxy-4'-chlorobenzophenone into a three-necked flask equipped with electric stirring, a thermometer, and a reflux condenser. After stirring for 10 minutes, add 60g of sodium hydroxide, and control the stirring speed at 350r / min , then added dropwise 45 g of chloroform at 20-30° C., and slowly raised the temperature after the dropwise addition, and refluxed at 58-60° C. for 3.5 hours.

[0024] After the reflux reaction is finished, acetone is recovered by distillation below 70°C.

[0025] After the recovery of acetone is completed, add 100g of appropriate amount of water (1) and 130g of toluene, add 36% hydrochloric acid (about 60g) dropwise under stirring, acidify to pH=3.5-4.5, and then add an appropriate amount of 100g of water (2) to promote the feed liquid The medium salts are completely dissolved, the feed liquid is cooled to room temperature, filtered, and the filter cake is dried to obtain fenofibric acid.

[0026] After testi...

Embodiment 2

[0028] Add 120g of acetone and 50g of 4-hydroxy-4'-chlorobenzophenone into a three-necked flask equipped with electric stirring, thermometer and reflux condenser, and stir for about 10 minutes, add 60g of sodium hydroxide, and control the stirring speed at 350r / min .

[0029] Then 45g of chloroform was added dropwise at 20-30°C, and after the addition of chloroform was completed, it was kept at 20-30°C for 1.5h;

[0030] After the heat preservation is over, the feed liquid is heated and refluxed at 58-60°C for 3.5h.

[0031] Recover acetone by distillation below 70°C, then add an appropriate amount of 50g of water (3), conduct vacuum distillation below 75°C, and continue to recover acetone.

[0032] Then add 100g appropriate amount of water (1) and 130g toluene to the feed liquid, add dropwise 36% hydrochloric acid (about 60g), the feed liquid is acidified to pH=3.5~4.5, and then add 100g appropriate amount of water (2) to promote the completion of salts Dissolve, cool the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com