Method for quickly synthesizing diethyl hypophosphite at low pressure, and diethyl hypophosphite product and application of product

A technology of diethyl hypophosphite and hypophosphite, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the hidden safety hazards and product shortages of increasing equipment investment and operation. The problems of economy and long reaction time can reduce the amount of ethylene, reduce the investment cost and improve the synthesis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

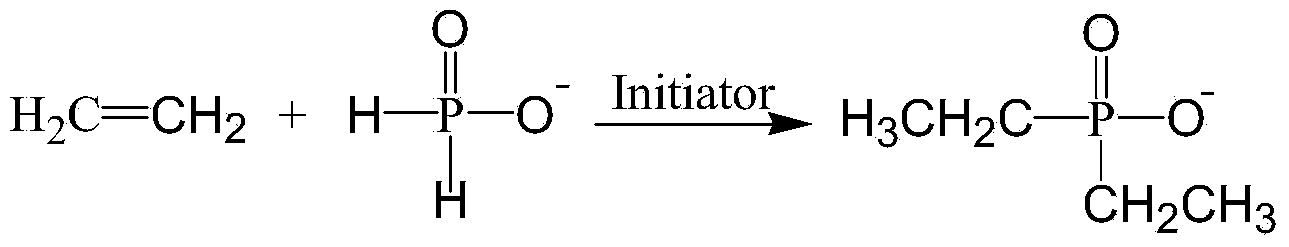

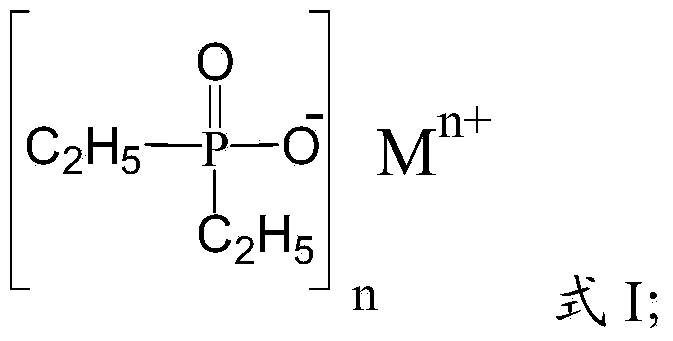

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 274.1g of sodium hypophosphite in 1600g of water, then transfer the solution to a 3L autoclave, add 3g of concentrated sulfuric acid and 36g of n-butanol, heat up to 95°C, feed ethylene, and control the pressure in the autoclave to be constant at 0.3MPa , and then use a peristaltic pump to continuously pump a sodium percarbonate solution with a concentration of 2%, and the reaction ends in about 2.5 hours. The reactor was depressurized and cooled to about 90°C, and 775 g of 46% aluminum sulfate solution of octadecahydrate was added to the reactor within 60 minutes, and a white precipitate was gradually precipitated. Filter, wash with hot water, and dry under vacuum at 150°C. The yield was 96.3%. The precipitates were subjected to elemental analysis by energy spectrum, and the results are shown in Table 1.

[0037] Table 1

[0038] element

Embodiment 2

[0040] The implementation process is the same as in Example 1, except that the pressure in the reactor is constant at 0.5 MPa, the time required for the completion of the reaction is 2 h, and the final yield of the precipitate obtained is 95.7%. The precipitates were subjected to elemental analysis by energy spectrum, and the results are shown in Table 2.

[0041] Table 2

[0042] element

Embodiment 3

[0044] The implementation process was the same as in Example 1, except that the pressure in the reactor was constant at 0.1 MPa, the time required for the completion of the reaction was 3 h, and the final yield of the precipitate was 94.5%. The precipitates were subjected to elemental analysis by energy spectrum, and the results are shown in Table 3.

[0045] table 3

[0046] element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com