PC (Polycarbonate)/PET (Polyethylene Terephthalate) composition and preparation method thereof

A technology of composition and transesterification inhibitor, which is applied in the field of materials, can solve problems such as poor compatibility, affecting the performance and application of blending systems, and achieve the effects of easy control, high flame retardancy, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

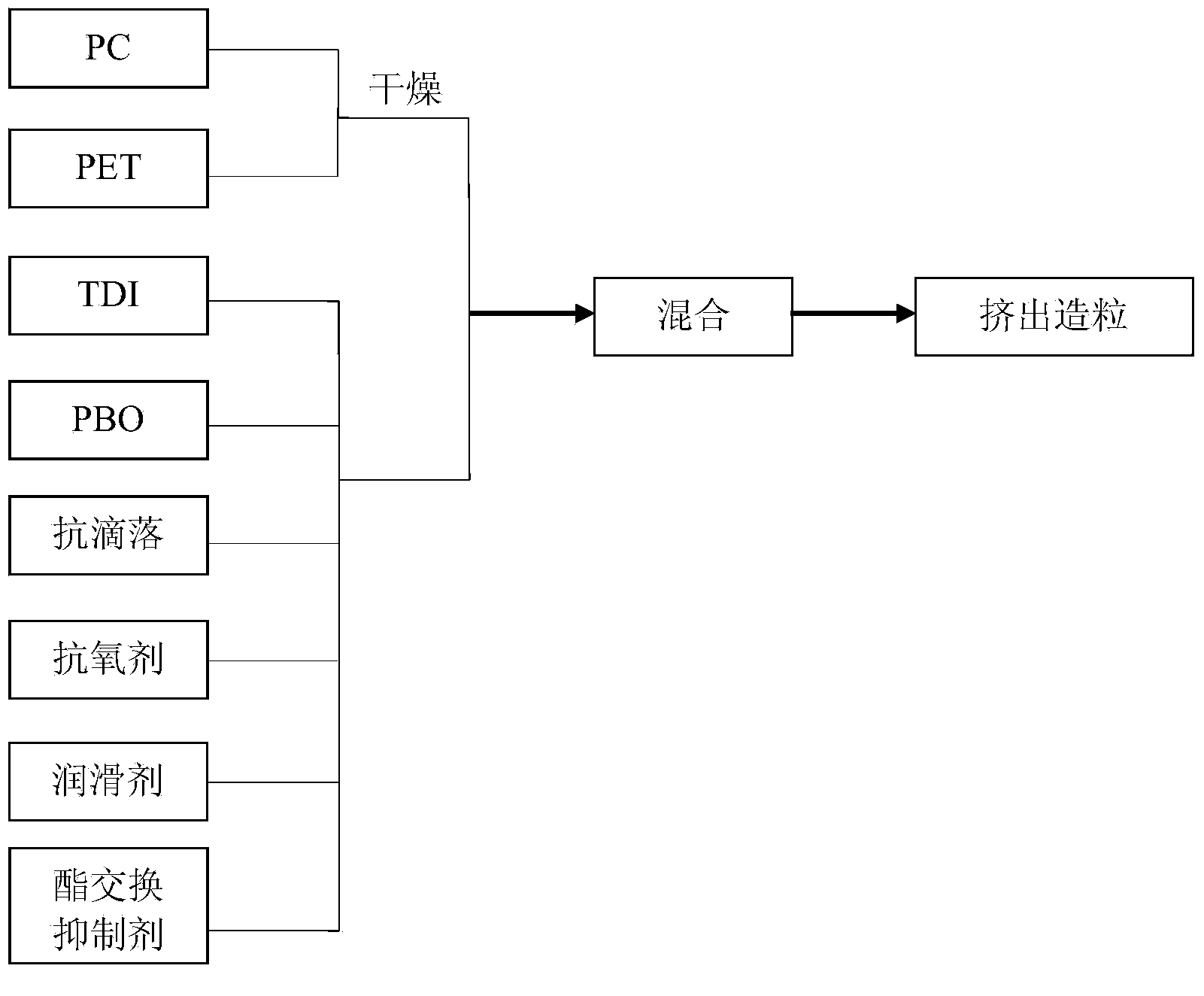

Method used

Image

Examples

Embodiment 1

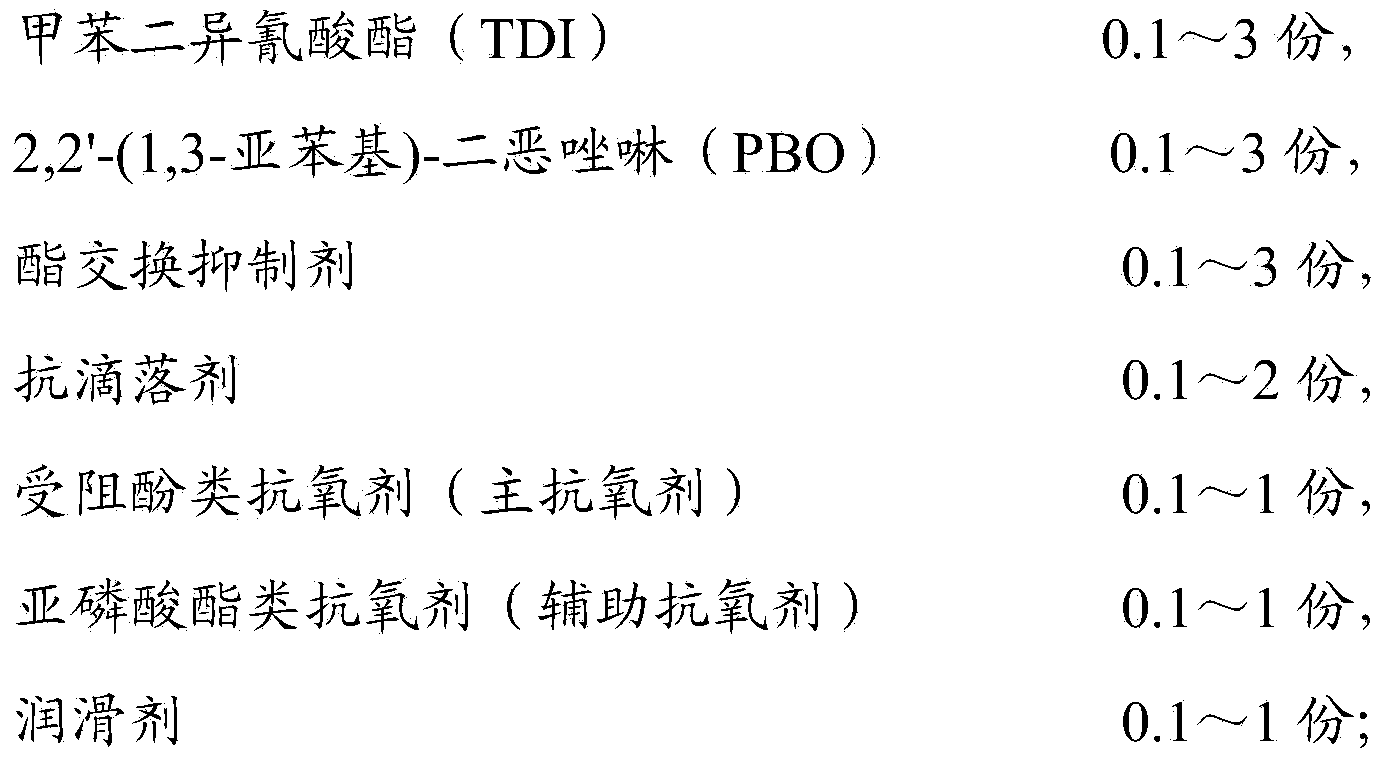

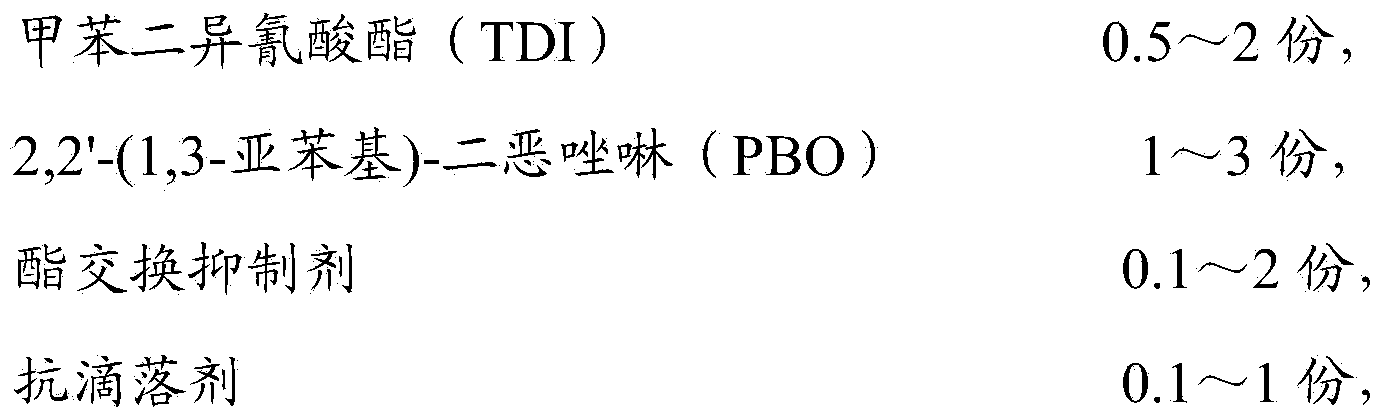

[0103] In this example, a PC / PET composition is prepared by an in-situ reaction compatibilization method, which is prepared from the following raw materials:

[0104] Polycarbonate (PC, number average molecular weight is 30000) 95 parts,

[0105] 5 parts of polyethylene terephthalate (PET, intrinsic viscosity 0.93dL / g),

[0106] The sum of parts by weight of polycarbonate (PC) and polyethylene terephthalate (PET) is 100 parts,

[0107]

[0108] The preparation method of above-mentioned PC / PET composition, comprises the following steps:

[0109] (1) Place the polycarbonate (PC) at 110°C and dry it for 4 hours, and place the polyethylene terephthalate (PET) at 80°C and dry it for 4 hours. After cooling, the polycarbonate and Add polyethylene terephthalate to the high-speed mixer for pre-mixing;

[0110] (2) Toluene diisocyanate (TDI), 2,2'-(1,3-phenylene)-bisoxazoline (PBO), transesterification inhibitor triphenyl phosphate (TPP), anti-dripping agent , hindered phenolic a...

Embodiment 2

[0114] In this example, a PC / PET composition is prepared by an in-situ reaction compatibilization method, which is prepared from the following raw materials:

[0115] Polycarbonate (PC, number average molecular weight is 15000) 90 parts,

[0116] 10 parts of polyethylene terephthalate (PET, intrinsic viscosity 0.64dL / g),

[0117] The sum of parts by weight of polycarbonate (PC) and polyethylene terephthalate (PET) is 100 parts,

[0118]

[0119] The preparation method of above-mentioned PC / PET composition, comprises the following steps:

[0120] (1) Place the polycarbonate (PC) at 110°C and dry it for 4 hours, and place the polyethylene terephthalate (PET) at 80°C and dry it for 4 hours. After cooling, the polycarbonate and Add polyethylene terephthalate to the high-speed mixer for pre-mixing;

[0121] (2) Toluene diisocyanate (TDI), 2,2'-(1,3-phenylene)-bisoxazoline (PBO), transesterification inhibitor triphenyl phosphate (TPP), anti-dripping agent , hindered phenolic ...

Embodiment 3

[0125] In this example, a PC / PET composition is prepared by an in-situ reaction compatibilization method, which is prepared from the following raw materials:

[0126] Polycarbonate (PC, number average molecular weight is 23000) 85 parts,

[0127] Polyethylene terephthalate (PET, intrinsic viscosity 0.72dL / g) 15 parts,

[0128] The sum of parts by weight of polycarbonate (PC) and polyethylene terephthalate (PET) is 100 parts,

[0129]

[0130] The preparation method of above-mentioned PC / PET composition, comprises the following steps:

[0131] (1) Place the polycarbonate (PC) at 110°C and dry it for 4 hours, and place the polyethylene terephthalate (PET) at 80°C and dry it for 4 hours. After cooling, the polycarbonate and Add polyethylene terephthalate to the high-speed mixer for pre-mixing;

[0132] (2) Toluene diisocyanate (TDI), 2,2'-(1,3-phenylene)-bisoxazoline (PBO), transesterification inhibitor triphenyl phosphite (TPPi), anti-dripping Agent, hindered phenolic ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com