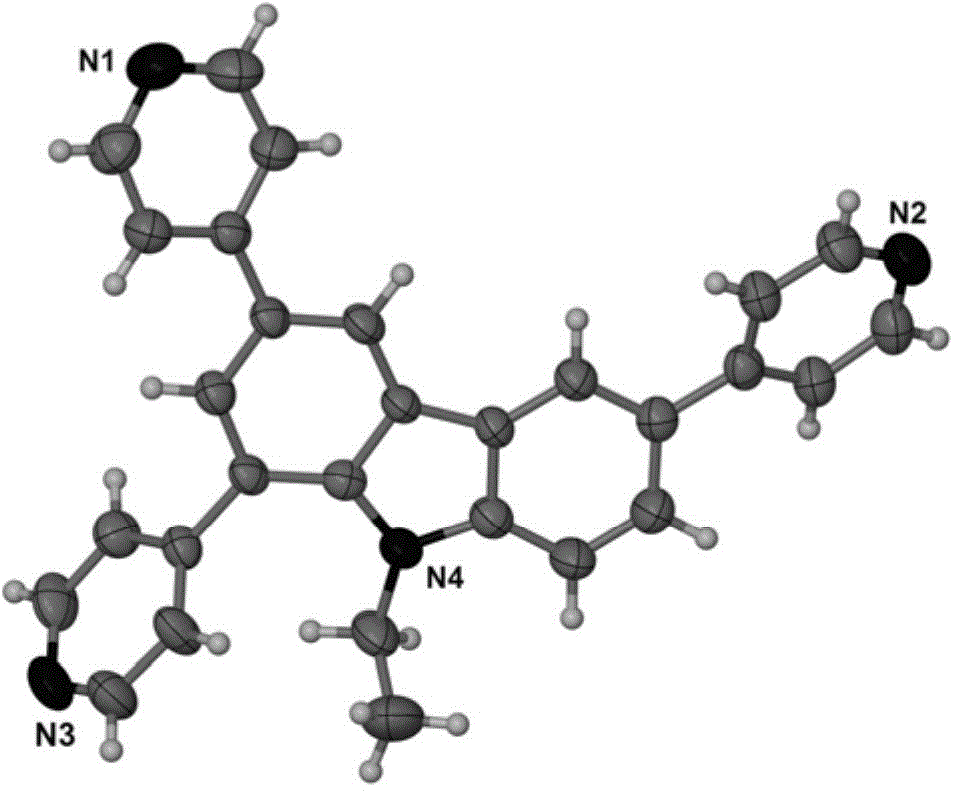

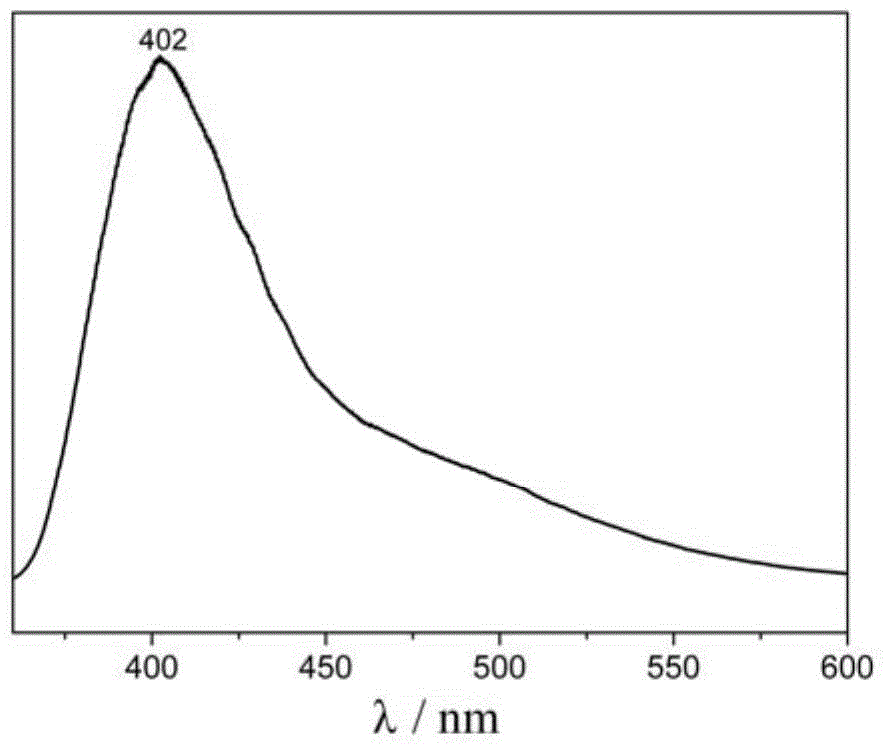

A kind of tripyridine carbazole purple fluorescent material

A technology of tripyridine carbazole purple and pyridine carbazole purple, applied in the field of material chemistry, can solve problems such as hindering the pace of full-color device and white light device industry and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 1,3,6-tribromo-9-ethylcarbazole (1.296g, 3mmol), 4-pyridineboronic acid (1.106g, 9mmol) and potassium carbonate (2.073g, 15mmol) into a 250mL reaction device , then add toluene / ethanol / water (75mL / 15mL / 5mL) mixed solvent; take out the air in the reaction device and fill it with nitrogen, and repeat the operation 3 times; then weigh tetrakis (triphenylphosphine) palladium (0.693g , 0.3mmol) into the reaction mixture, vacuumize and fill with nitrogen, repeat the operation 3 times; reflux reaction at 80°C for 1.5 days under nitrogen atmosphere; cool to room temperature after the reaction, separate the liquid, and extract the aqueous phase with dichloromethane for 3 time, combine the organic phases, wash the organic phases with saturated brine for 3 times, then dry them with anhydrous magnesium sulfate, and filter the filtrate under reduced pressure; remove the solvent in the filtrate to obtain a crude product, then use ethyl acetate as a rinse The reagent was separat...

Embodiment 2

[0022] Weigh 1,3,6-tribromo-9-ethylcarbazole (0.864g, 2mmol), 4-pyridineboronic acid (2.213g, 18mmol) and potassium carbonate (8.293g, 60mmol) into a 250mL reaction device , then add toluene / ethanol / water (90mL / 60mL / 18mL) mixed solvent; take out the air in the reaction device and fill it with nitrogen, and repeat the operation 3 times; then weigh tetrakis (triphenylphosphine) palladium (0.0578g , 0.05mmol) into the reaction mixture, vacuumize and fill with nitrogen, repeat the operation 3 times; under nitrogen atmosphere, reflux reaction at 85°C for 3 days; after the reaction, cool to room temperature, separate the liquid, and extract the aqueous phase with dichloromethane 3 times, the organic phases were combined, washed 3 times with saturated brine, and then dried with anhydrous magnesium sulfate, and the filtrate was filtered under reduced pressure; the solvent in the filtrate was removed to obtain a crude product, and then ethyl acetate was used as the eluting agent. Separ...

Embodiment 3

[0024] Weigh 1,3,6-tribromo-9-ethylcarbazole (1.296g, 3mmol), 4-pyridineboronic acid (1.475g, 12mmol) and potassium carbonate (3.455g, 25mmol) into a 250mL reaction device , then add toluene / ethanol / water (90mL / 30mL / 10mL) mixed solvent; take out the air in the reaction device and fill it with nitrogen, and repeat the operation 3 times; then weigh tetrakis (triphenylphosphine) palladium (0.173g , 0.15mmol) into the reaction mixture, vacuumize and fill with nitrogen, repeat the operation 3 times; reflux reaction at 95°C for 2 days under nitrogen atmosphere; naturally cool to room temperature after the reaction, separate the liquid, and use dichloromethane for the water phase Extracted 3 times, combined the organic phase, washed the organic phase 3 times with saturated brine, dried with anhydrous magnesium sulfate, and filtered the filtrate under reduced pressure; removed the solvent in the filtrate to obtain a crude product, and then used ethyl acetate as The eluent was separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com