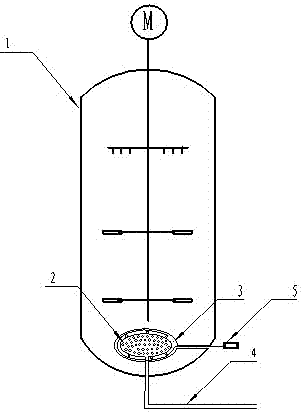

Air distributor of fermentation tank utilizing ultrasonic waves for defoaming

An air distributor and fermenter technology, which is applied to specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biochemical instrument, etc., can solve the problem of not effectively eliminating air bubbles, and save electricity and energy Consumption, increase fermentation dissolved oxygen, and improve the effect of fermentation product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

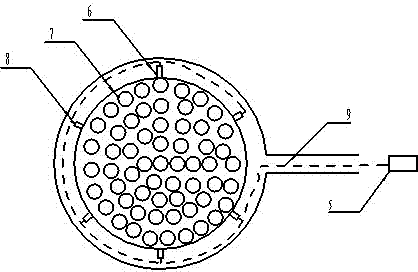

[0029] Example 2 The structure of the fermenter air distributor using ultrasonic defoaming can still refer to the attached figure 1 , but different from Example 1, the volume of the fermentor is 500m 3 , the diameter of the air distributor 2 is 4m, 1.5m away from the bottom of the fermenter shell 1, and the diameter of the annular steel pipe 3 is 90cm. The transducers 6 are arranged inside the annular steel pipe 3 and are connected by welding, and there are 8 transducers.

[0030] Example 3 The structure of the fermenter air distributor using ultrasonic defoaming can still refer to the attached figure 1 , but different from Example 1, the volume of the fermenter is 350m 3 , the diameter of the air distributor 2 is 3.5m, 1.25m away from the bottom of the fermenter shell 1, and the diameter of the annular steel pipe 3 is 65cm. The transducers 6 are arranged inside the annular steel pipe 3 and connected by welding, and there are 6 transducers.

[0031] According to the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com