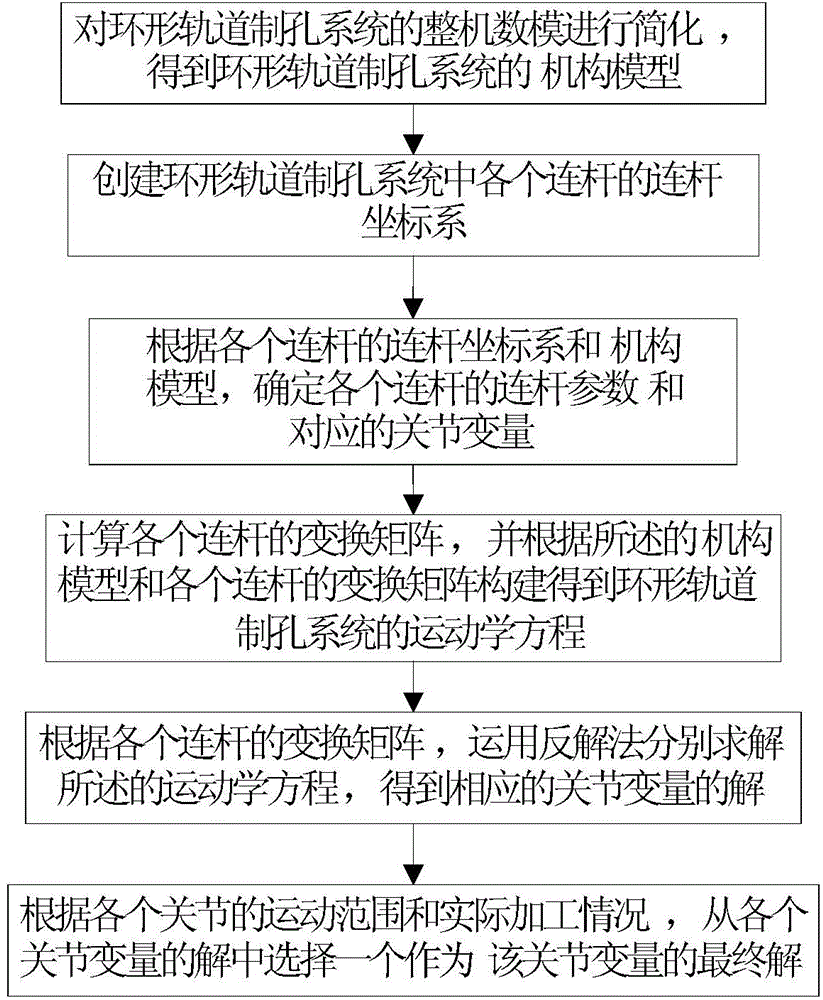

Method for acquiring joint variables by inversely solving kinematical equation of annular track hole making system

A technology of kinematic equations and circular orbits, applied in the direction of digital control, electrical program control, etc., can solve the problems of increased hole-making workload, high precision, and low hole-making efficiency, simplifying the calculation and analysis process, and improving the calculation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below with reference to the drawings and specific embodiments.

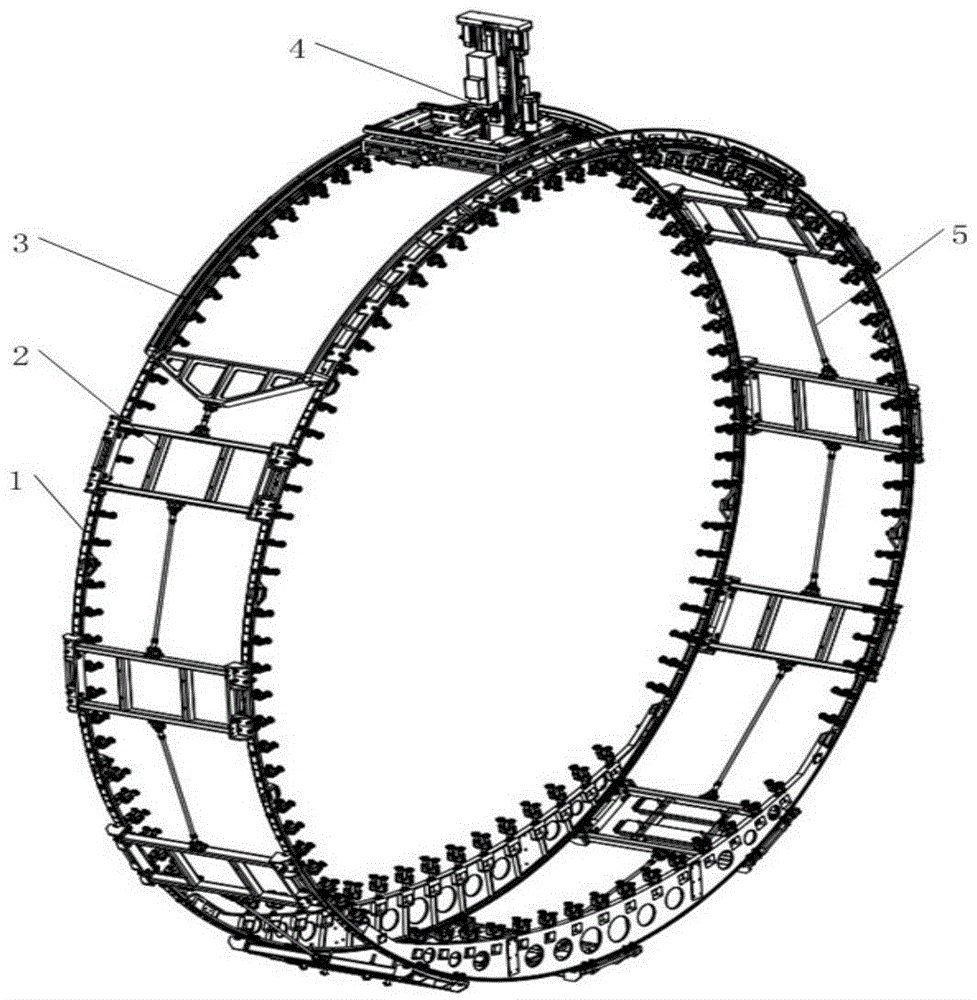

[0060] Such as figure 1 As shown, the hole-making device of this embodiment includes: an annular track module 1 , a track cage module 2 , an arc-shaped track module 3 , an automatic hole-making unit 4 and a cage link (link) 5 . The circular track module 1 is placed outside the aircraft fuselage, and the track holder module 2 is used to maintain the shape of the circular track module 1, and is connected with the arc track module 3 to form a ring around the circular track module 1, which is automatically made The hole unit 4 is slidingly fitted on the arc track module 3 .

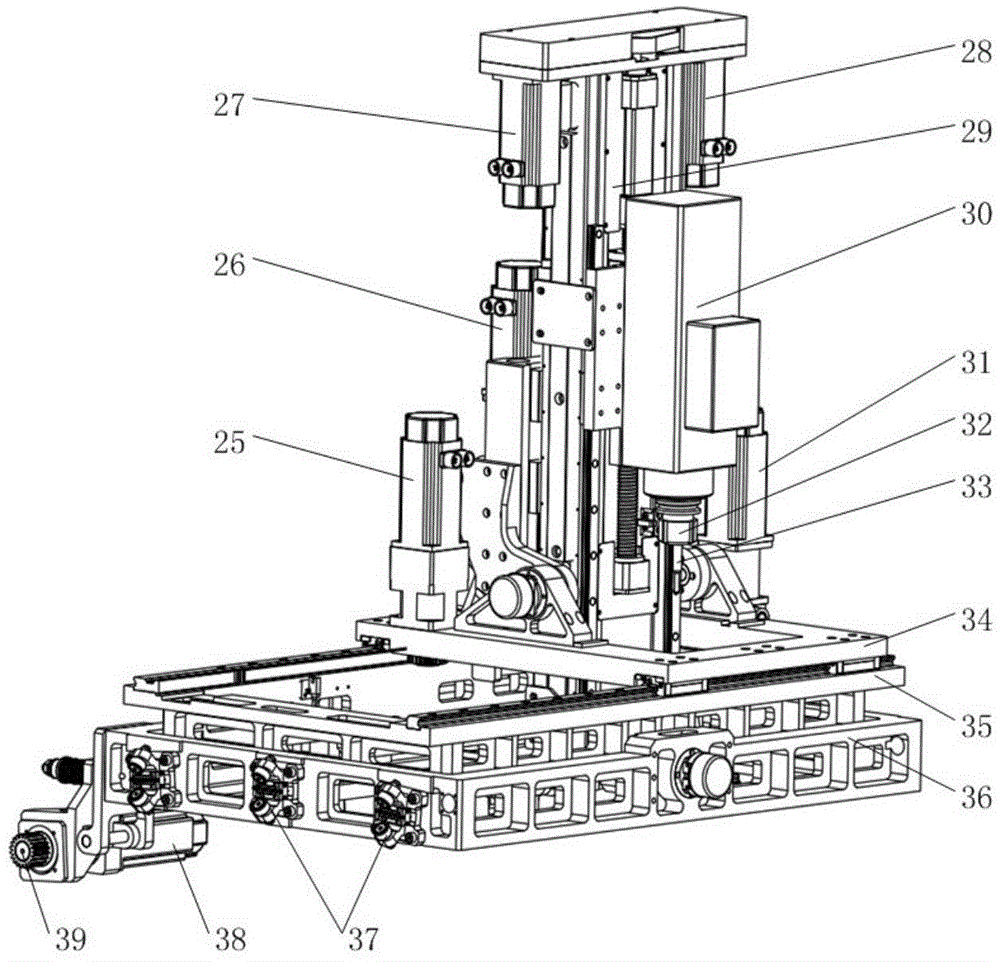

[0061] Such as figure 2 As shown, the automatic hole making unit 4 includes: Y-axis servo motor 25, B-axis servo motor 26, Z1-axis servo motor 27, Z2-axis servo motor 28, intermediate pallet 29, electric spindle 30, A-axis servo motor 31, fast Tool changing handle 32, cutting tool 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com