Marine petroleum drilling machine integrated network redundancy monitoring system

An offshore oil and monitoring system technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low reliability and stability, inconvenient operation and maintenance, complicated control, etc., and achieve a simple structure of software and hardware. , reduce economic losses, the effect of clock synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

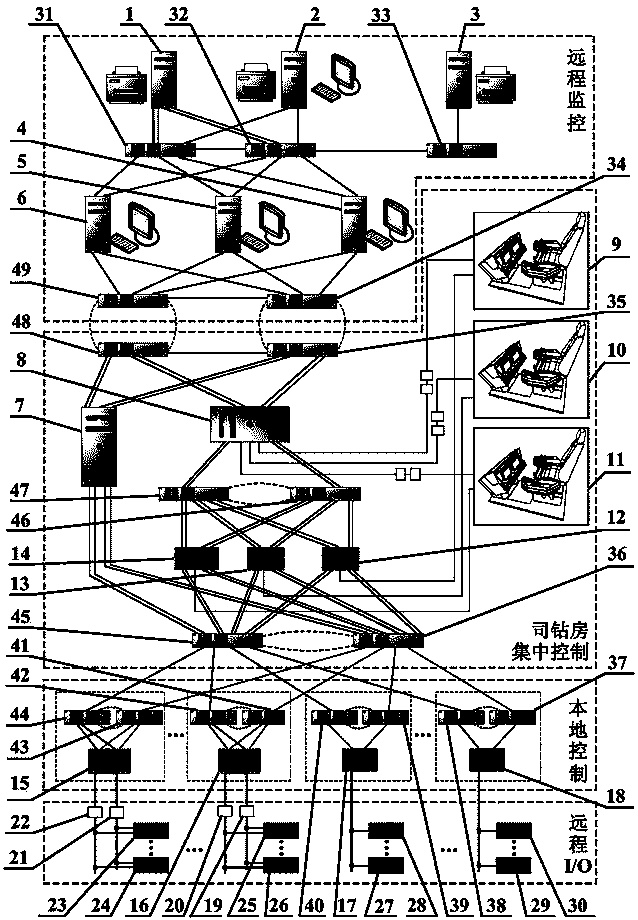

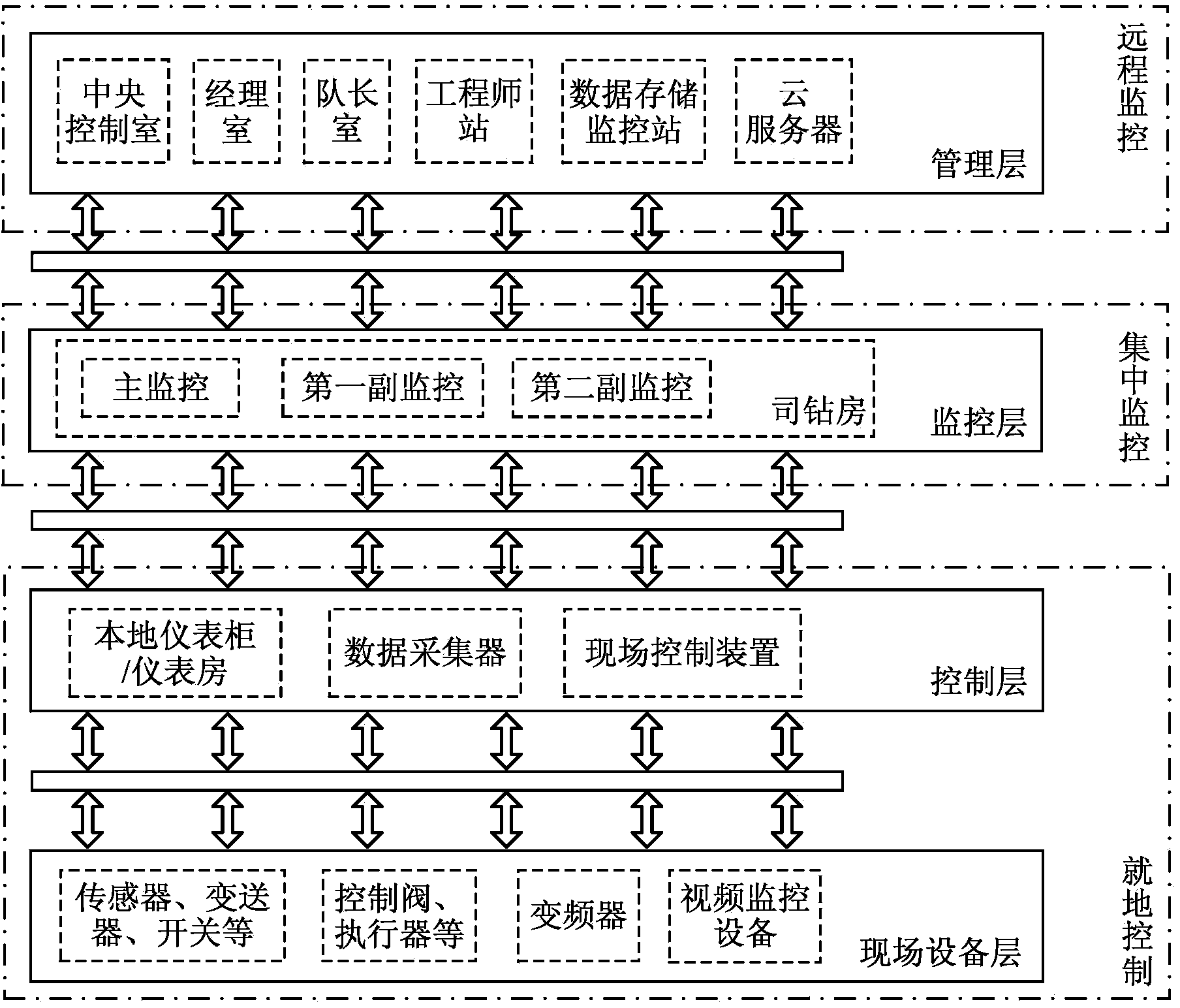

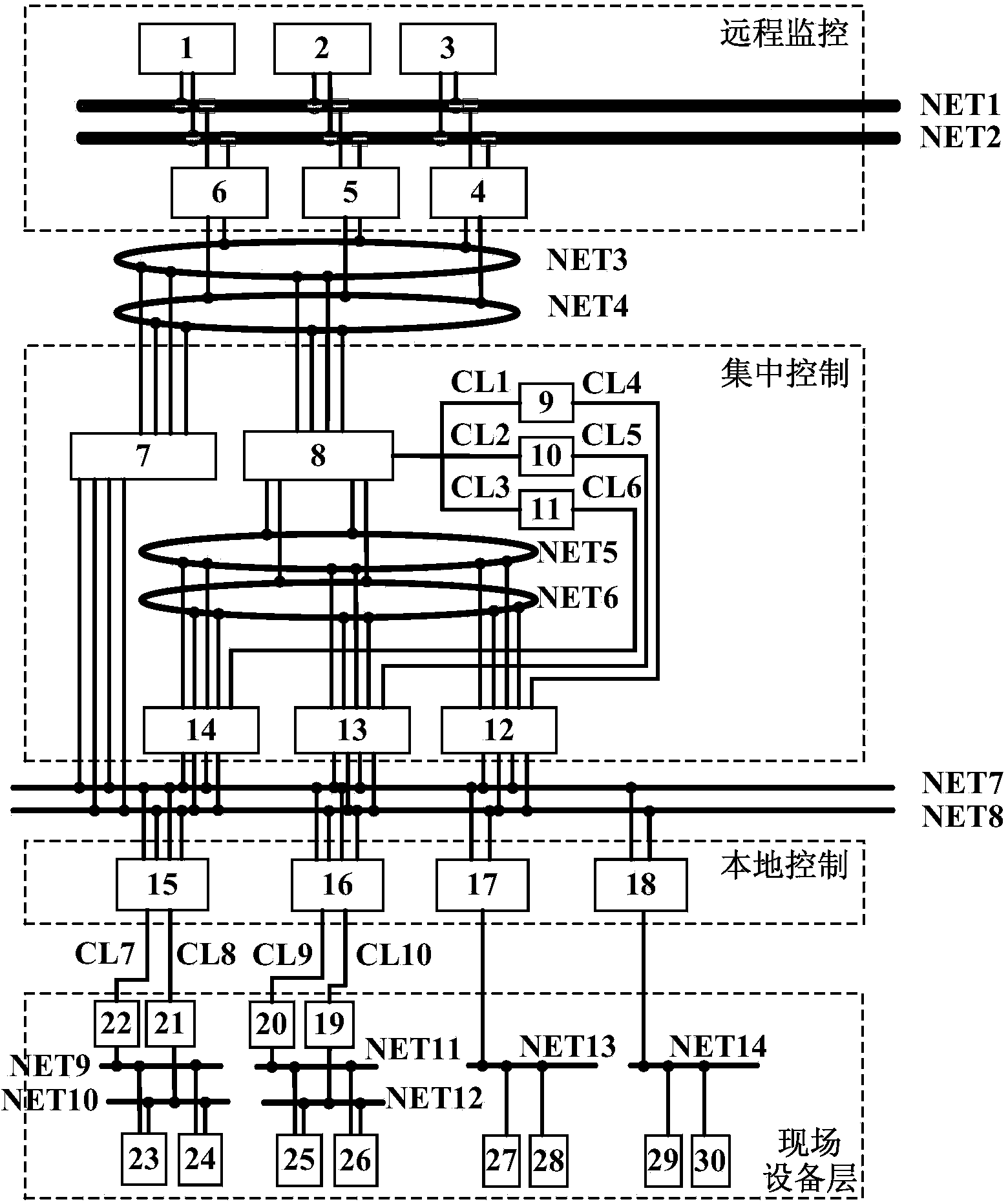

[0041] see figure 1 , the offshore oil drilling rig integrated network redundancy monitoring system of the present invention includes a network structure of "3 networks and 4 layers": "3 networks" are real-time Ethernet, real-time Ethernet, and field bus from top to bottom; "4 layers" from top to bottom From top to bottom are the management layer, monitoring layer, control layer and field device layer. The management layer can realize remote monitoring, the monitoring layer can realize centralized monitoring, and the control layer and field device layer can realize local control. The monitoring layer and the management layer are connected through a dual redundant Ethernet switch; the control layer and the monitoring layer are connected through a du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com