A metal double membrane bioreactor for sewage treatment

A membrane bioreactor, bioreactor technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the treatment cost and operation scale limit non-woven membrane bioreaction To achieve good pollutant removal effect, alleviate membrane fouling, and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The car wash of a chemical transportation company produces an average of 150 cubic meters of waste water for washing outside the car every day. The main pollution indicators are shown in Table 1.

[0019] Table 1 Characteristics of water quality indicators for washing wastewater outside the vehicle

[0020] index pH COD (mg / L) SS (mg / L) Oil (mg / L) waste water 7.3 156 1329 20

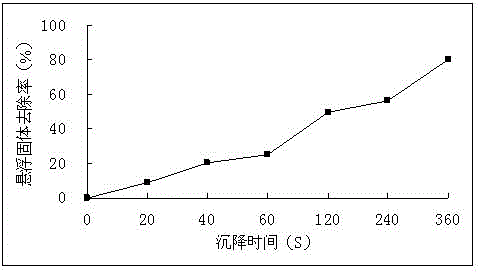

[0021] Because the actual car wash wastewater has high turbidity and contains some solids with larger particles. The results of the suspended solids settling experiment were as follows: figure 2 As shown, the settling characteristics of suspended solids in wastewater from vehicle flushing.

[0022] It can be seen that the sedimentation performance of suspended solids in wastewater is good, and after 6 minutes of sedimentation, the removal rate of suspended solids (medium-speed quantitative filter paper filtration) can reach 80%. Therefore, firstly, the primary se...

Embodiment 2

[0027] In a printing and dyeing wastewater treatment plant of an enterprise, the COD value of the treated effluent is 100-120mg / L, and the current new standard requires it to be below 60mg / L. Ozone + biological activated carbon, Fenton reagent method, activated carbon adsorption and other processes have been used for advanced treatment, but the results are not satisfactory, or the investment and operation costs are unacceptable.

[0028] Using metal iron-double-layer non-woven membrane bioreactor, the design water flux is 40L / m2.h. After running for a period of time, the system treatment effect is stable, and the system effluent COD can meet the treatment requirements, and sometimes the effluent COD value can be less than 30mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com