Energy-saving and emission-reducing town sewage treatment system

A technology for urban sewage, energy saving and emission reduction, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems to achieve the effect of stable hydraulic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

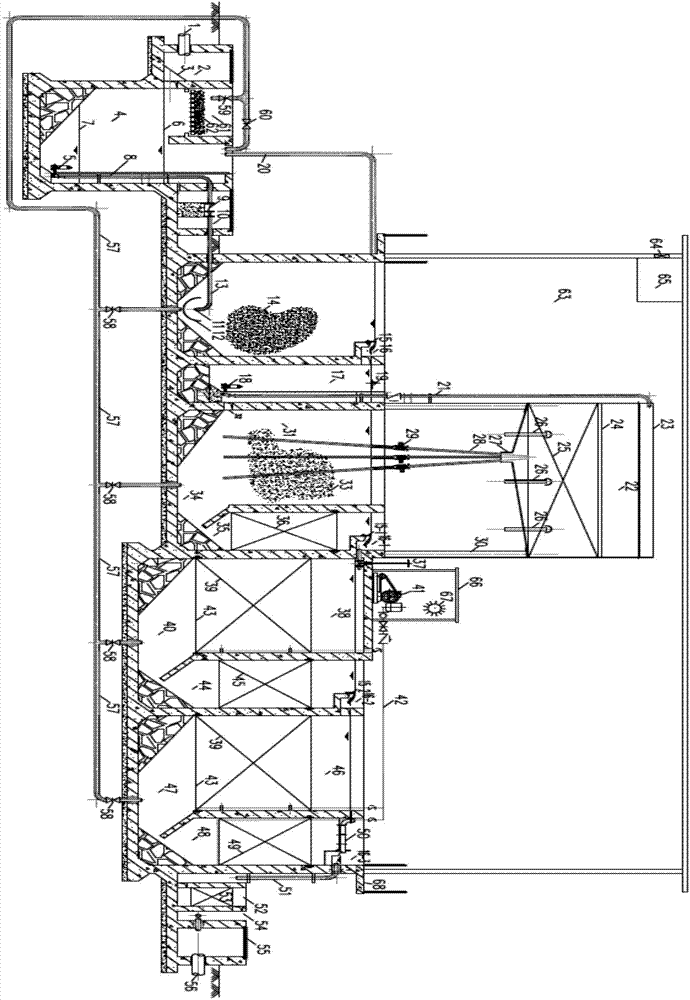

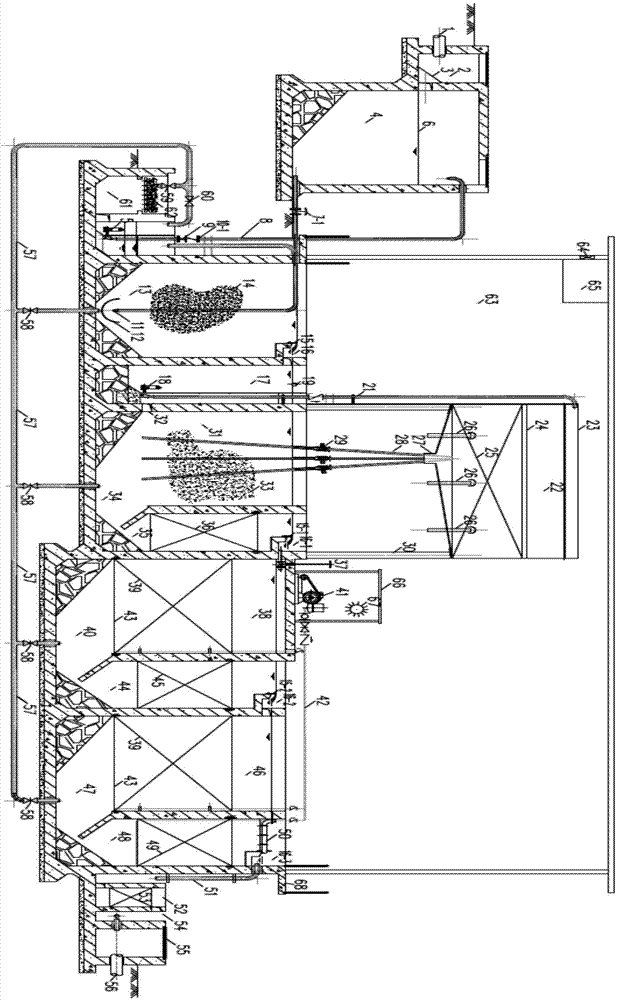

[0080] Embodiment 1 The structure and technology of sewage treatment system of the present invention

[0081]The lifting type is used as the leading process technology to make an explanation, see the structure figure 1 :

[0082] 1. Sewage is collected through the municipal pipe network, and enters the grille pool 2 at the front end of the sewage treatment device from the water inlet pipe 1. Artificial grilles or mechanical grilles 3 are installed in the grille pool 2 to remove larger sewage that may block The solid matter in the self-stirring lift pump 5 is regularly transported out for disposal.

[0083] The sewage treated by the grid 3 enters the adsorption pool 4, and the sewage self-stirring lifting pump 5 is installed in the adsorption pool 4, and the self-stirring lifting pump 5 realizes high water level 6 operation and low water level 7 shutdown. Sewage self-stirring lift pump 50 is preferred to choose the automatic stirring sewage pump, which is characterized by: th...

Embodiment

[0134] Embodiment New small town processing experiment

[0135] Newly built small towns, the annual average climate is around 18°C, the average minimum temperature in winter is 6-8°C, the summer is hotter, and the daily maximum temperature in July and August is above 35°C. The scale of sewage treatment is 5,000 tons / day (250 tons / hour), implemented in two phases, the scale of sewage treatment in the first phase is 2500 tons / day (125 tons / hour).

[0136] 1. Sewage is treated by lifting, and the structural units are as follows:

[0137] 1. There are four groups of adsorption pools, and the process size of a single group is:

[0138] 4.8m×4.8m×4.5m, the pool capacity is 414.72m 3 ;

[0139] 2. There are four groups of anoxic pools, and the process size of a single group is:

[0140] 4.8m×4.8m×4.5m, the pool capacity is 414.72m 3 ;

[0141] 3. There are four groups of aeration tanks, and the process size of a single group is:

[0142] 7.5m×4.8m×4.9m, the pool capacity is 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com