A method for preparing ethylbenzene from alkylation tail gas after catalytic dry gas is used to prepare styrene

A styrene and dry gas technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as unavailability, and achieve the effects of low cost, low reaction temperature and strong recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

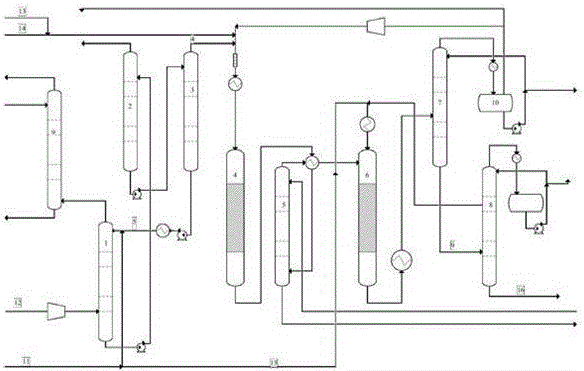

[0049] The present embodiment 1 provides a kind of such as figure 1 Shown a kind of method that ethylbenzene is produced by the alkylation tail gas after catalyzed dry gas system styrene, comprises the following steps:

[0050] 1) Hydrocarbonized tail gas 11 is pressurized to 1.7MPa by compressor and then enters the bottom of absorption tower 1; at the same time, benzene at 10°C is used as absorbent to enter the top of absorption tower 1; alkylated tail gas 11 and benzene cross-flow in absorption tower 1 After the contact, the tail gas is discharged from the top of the absorption tower 1, and the bottom liquid is benzene rich in ethane;

[0051] The tower top temperature 10 ℃ of described absorption tower 1, the tower bottom temperature 18 ℃ of absorption tower 1; Pressure 1.7MPa;

[0052] 2) The ethane-rich benzene is pumped into the desorption tower 2 for desorption;

[0053] The pressure inside the analysis tower 2 is 1.0MPa, the temperature at the top of the analysis to...

Embodiment 2

[0078] This embodiment provides a figure 1 Shown a kind of method that ethylbenzene is produced by the alkylation tail gas after catalyzed dry gas system styrene, comprises the following steps:

[0079] 1) Hydrocarbonized tail gas 11 is pressurized to 2.8 MPa by the compressor and then enters the bottom of absorption tower 1; at the same time, benzene at 14°C is used as absorbent to enter the top of absorption tower 1; alkylated tail gas 11 and benzene cross-flow in absorption tower 1 After the contact, the tail gas is discharged from the top of the absorption tower 1, and the bottom liquid is benzene rich in ethane;

[0080] The tower top temperature 20 ℃ of described absorption tower 1, the tower bottom temperature 25 ℃ of absorption tower 1; Pressure 2.8MPa;

[0081] 2) The ethane-rich benzene is pumped into the desorption tower 2 for desorption;

[0082] The pressure inside the analysis tower 2 is 1.5MPa, the temperature at the top of the analysis tower 2 is 30°C, and t...

Embodiment 3

[0107] This embodiment provides a figure 1 Shown a kind of method that ethylbenzene is produced by the alkylation tail gas after catalyzed dry gas system styrene, comprises the following steps:

[0108] 1) The hydrocarbonized tail gas is pressurized by the compressor to 2.0MPa and then enters the bottom of the absorption tower 1; at the same time, benzene at 12°C is used as the absorbent to enter the top of the absorption tower 1; after the cross-flow contact between the hydrocarbonated tail gas and benzene in the absorption tower 1 , the tail gas is discharged from the top of the absorption tower 1, and the bottom liquid is benzene rich in ethane;

[0109] The tower top temperature 12 ℃ of described absorption tower 1, the tower bottom temperature 22 ℃ of absorption tower 1; Pressure 2.0MPa;

[0110] 2) The ethane-rich benzene is pumped into the desorption tower 2 for desorption;

[0111] The pressure inside the analysis tower 2 is 1.2MPa, the temperature at the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com