Method for preparing fatty alcohol through hydrogenation of fatty acid methyl ester in presence of temperature control catalytic system

A technology of fatty acid methyl ester and catalytic system, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of short catalyst life, large mass transfer and diffusion resistance, etc. The effect of good performance and good temperature control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

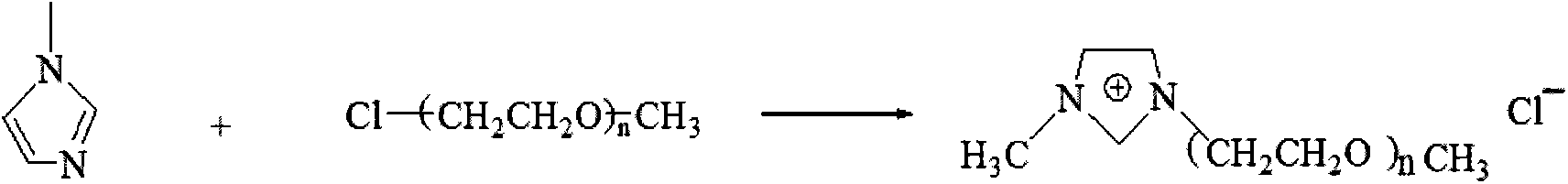

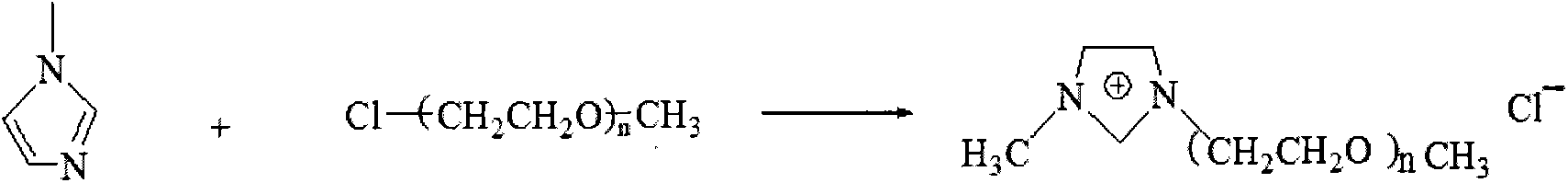

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the temperature control ionic liquid catalytic system Pd / IL PEG-750 (Pd content is 1%) 1.0g and fatty acid methyl ester 10.0g are added to the reaction kettle, and after being replaced with 1-2MPa hydrogen for 5 times, then filled with 6Mpa hydrogen, kept at 210°C for 4 hours, after the reaction, take out the reaction vessel Kettle, cooled to room temperature, depressurized to open the kettle, the upper product was taken out, and the organic solvent was removed by distillation under reduced pressure to obtain the product fatty alcohol, and the hydroxyl value and iodine value were measured. The product fatty alcohol had a hydroxyl value of 195mgKOH / g and an iodine value of 20g / 100g. The catalyst in the lower layer is re-added to the reactants without any treatment, and is directly recycled.

Embodiment 2

[0027] Embodiment 2: the temperature control ionic liquid catalytic system Pd / IL PEG-750 (Pd content is 5%) 0.8g, fatty acid methyl ester 10.0g are added to the reaction kettle, after 5 times of replacement with 1-2MPa hydrogen, then filled with 5Mpa hydrogen, 200 ℃ heat preservation reaction for 5h, after the reaction, take out the reaction kettle Kettle, cooled to room temperature, depressurized and opened the kettle, the upper product was taken out, and the organic solvent was removed by distillation under reduced pressure to obtain the product fatty alcohol. The hydroxyl value and iodine value of the product fatty alcohol were measured, and the product fatty alcohol had a hydroxyl value of 170mgKOH / g and an iodine value of 30g / 100g. The catalyst in the lower layer is re-added to the reactants without any treatment, and is directly recycled.

Embodiment 3

[0028] Embodiment 3: the temperature control ionic liquid catalytic system Pd / IL PEG-400(Pd content is 10%) 1.2g and fatty acid methyl ester 10.0g are added to the reaction kettle, replaced with 1-2MPa hydrogen for 5 times, then filled with 4Mpa hydrogen, and kept at 190°C for 6h. After the reaction, take out the reaction kettle Kettle, cooled to room temperature, depressurized and opened the kettle, the upper product was taken out, and the organic solvent was removed by distillation under reduced pressure to obtain the product fatty alcohol, and the hydroxyl value and iodine value were measured. The product fatty alcohol had a hydroxyl value of 148mgKOH / g and an iodine value of 38g / 100g. The catalyst in the lower layer is re-added to the reactants without any treatment, and is directly recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com