Pyrrolidine ionic liquid, and preparation method, electrolyte and capacitor thereof

A technology of ionic liquid and pyrrolidine, which is applied in the field of pyrrolidine ionic liquid and its preparation, can solve the problems of stability, safety and electrochemical performance to be improved, and achieve the effect of improving excellent electrochemical performance, stability and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation process of the pyrrolidine ionic liquid electrolyte of the present invention can be roughly divided into the following three steps:

[0036] Methyl pyrrolidine→alkylpyrrolidine halide→pyrrolidine ionic liquid→pyrrolidine ionic liquid electrolyte

[0037] The first step is to prepare alkylpyrrolidine halides through the reaction of methylpyrrolidine and haloalkane RX;

[0038] The reaction formula is as follows:

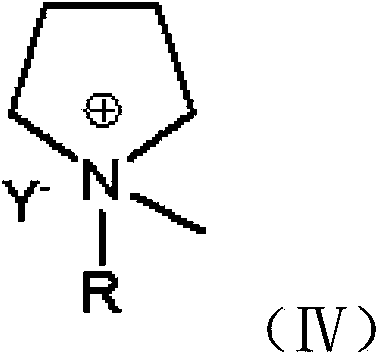

[0039]

[0040] Among them, X is a halogen, preferably chlorine, bromine or iodine atom; R is a methoxyalkyl group with the following general formula (II): CH 3 O(CH 2 ) n (II), wherein n is 2, 3 or 4;

[0041] The haloalkane RX here is more precisely a methoxy haloalkane, and the oxygen in the chemical formula is connected to the carbon in the form of an ether bond.

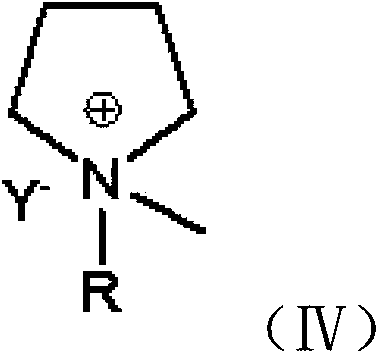

[0042] The second step is to prepare pyrrolidine ionic liquid through ion exchange carried out by inorganic salt MY and alkylpyrrolidine halide;

[0043] The reaction for...

Embodiment 1

[0061] The pyrrolidine ionic liquid provided in Example 1 is specifically: N-methoxyethyl-N-methylpyrrolidine tetrafluoroborate liquid ionic liquid, and its structural formula is:

[0062]

[0063] The preparation method of above-mentioned ionic liquid, comprises the following steps:

[0064] (a) Preparation of alkylpyrrolidine halides

[0065] Add 85g (1mol) of methylpyrrolidine and 104.0g (1.1mol) of methoxychloroethane into a 250ml flask respectively. in N 2 Under the protection of the atmosphere, the temperature was raised to 70° C., and the reaction was stirred for 40 h. Let stand to cool, and wash three times with ethyl acetate. Vacuum drying at 80° C. for 24 h gave a light yellow solid as N-methoxyethyl-N-methylpyrrolidine chloride salt with a yield of 80%.

[0066] (b) Preparation of pyrrolidine ionic liquid

[0067] Add 94.8g (0.5mol) N-methoxyethyl-N-methylpyrrolidine chloride salt, 57.8g (0.53mol) NaBF in 250ml flask 4 and 130ml of deionized water (that is,...

Embodiment 2

[0071] The pyrrolidine ionic liquid provided in Example 2 is specifically: N-methoxypropyl-N-methylpyrrolidine hexafluorophosphate ionic liquid, and its structural formula is:

[0072]

[0073] The preparation method of above-mentioned ionic liquid, comprises the following steps:

[0074] (a) Preparation of alkylpyrrolidine halides

[0075] Add 85g (1mol) of methylpyrrolidine and 160.7g (1.05mol) of methoxybromopropane into a 250ml flask respectively. in Ar 2 Under the protection of atmosphere, the temperature was raised to 60° C., and the reaction was stirred for 60 h. Let stand to cool, and wash three times with ethyl acetate. Vacuum drying at 80°C for 36 h gave N-methoxypropyl-N-methylpyrrolidine bromide as a light yellow solid with a yield of 81%.

[0076] (b) Preparation of pyrrolidine ionic liquid

[0077] In the 250ml flask, add 124.1g (0.5mol) N-methoxypropyl-N-methylpyrrolidine bromide, 92g (0.5mol) KPF 6 and 100ml of deionized water (that is, the molar volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com